Commitment to listening to customer needs is what allows you not only to have customers, but to develop long-term relations with them. Grow a reputation as a reliable business partner. And through that – grow your customers' base.

In 2020, an unprecedented epidemic swept through the world, radically changing people's everyday life, and shaking manufacturing industry profoundly. Some of the effects were not anticipated, leaving businesses in more risk than expected. Quarantines and lockdowns of affected suppliers left cracks in supply chains, sending manufacturers scattered around, looking for substitutes, to keep their production going.

The best way for companies to survive short-term market fluctuations is through advance risk management, medium- and long-term planning, and necessary and urgent changes and innovative thinking. From centralized manufacturing to decentralized manufacturing, it is an urgent challenge for all manufacturers to maintain the centralization and consistency of information, and even establish data centers.

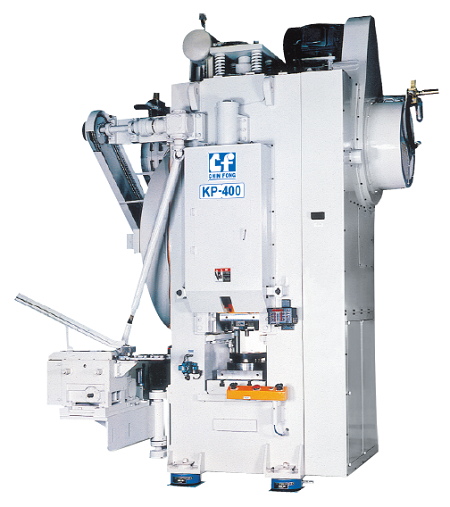

Smart machine is at the heart of Chin Fong’s technological innovations. Starting from single-press smart solution, the company has then moved on to multi press connection and cloud computing, linking ERP management and even AI computing system to analyze big data.

Chin Fong: Solution-driven provider/partner/supplier

Video Link: https://www.youtube.com/watch?v=MQrHsQUaR1U

Chin Fong is committed to the needs of its customers. They understand that the importance of intelligent transformation is the key to a customer’s future success. With decades of experience in equipment manufacturing, Chin Fong has encountered numerous customer cases involving automation integration of large production lines. They helped each client plan their ROBOT/AGV/ARV/AOI automation applications according to their needs and different stages of transformation.

Through professional machine selection consulting services, combined with "iForming PMS - Intelligent Forming Productivity Management System" solution, Chin Fong has always stood by their customers' side and become a solid partner.

However "to improve is to change; to be perfect is to change often". Following that idea, Chin Fong never stops developing new features and upgrading existing ones. Therefore, in response to the ever-expanding customer demands the company has implemented not only scanning code and fingerprint authentication to meet the workplace safety requirement, but also facial recognition and even iris recognition system.

Chin Fong iForming PMS Flexible Solution

Based upon its proven technical know-how, Chin Fong is promoting iForming, an intelligent forming solution. This trusted intelligent forming tool enables customers to quickly and cost-effectively introduce intelligent applications. Whether it is a generic stamping press, transfer press, forging press, or servo press, all can be integrated into one platform, allowing Chin Fong presses to provide customers with the best smart manufacturing solution for forming.

From a specification standpoint, this smart forming solution presents production process data in real time through a visual plant management software and hardware interface (also known as a Real-Time Situation Room), which can be used as a reference for production process, manufacturing management and decision optimization to transform a traditional stamping factory into a smart factory.

Chin Fong's smart factory solutions are ahead of the industry standards as they keep to strategically developing their products to provide a smart production model for their customers. Smart transformation should never be a headache. It should be the solution. With that in mind, Chin Fong is committed to helping its customers improve their manufacturing process through smart manufacturing and Industry 4.0.

Thus, the company has introduced a smart management system for supervisors to know the progress of their factories in real time. That improves traditional manpower and equipment management, and then extend to material and logistics management, and finally reaching the factory smart 4M1E (Man, Machine, Material, Method and Environment) management method.

In the early stage, Chin Fong observed that most customers were concerned about the high cost of introducing smart management solutions in their initial stages of transformation and development, not to mention the time cost and risk.

Therefore, Chin Fong developed its own iForming PMS system solution and implemented it in its own factory – which serves as a technology demonstrator. As the ultimate goal is to make smart manufacturing more accessible for customers, iForming PMS solutions currently comes with the machines as the added-value, not as an additional product.

After-sales service is an important point in Chin Fong's smart transformation solution. Chin Fong's sales visit customers along with their engineers and service staff to collect feedback and address technology-related customization needs. One of Chin Fong’s customer ever met system integration issue. Chin Fong thus worked with a third-party system provider to develop a common application-programming interface (API). This program combines enterprise resource planning and manufacturing execution system (ERP/MES) to respond quickly to the changes in production process. Thus, management decision makers can integrate this in the shop floor tracking system (SFT), linking data in a more compatible and convenient way.

iForming not only improves supply and demand forecast, but also lengthens response time. It gathers historical information through big data, and introduces AI machine learning. iForming integrates instant messages to notify customers proactively, which results in an actively growing and intelligent system, exclusively for customers. Recently, Chin Fong collaborated with ASUS and Axiomtek to create an intelligent forming defect detection solution, which is the latest upgrade of iForming’s extension suite.

The "Intelligent Forming Defect Detection Solution" is based on iForming's management system. It combines AI visual inspection system and high performance AI edge computing for highly efficient production real-time data and quality information aggregation, as a part of iForming's extended functions. The solution also features wave pattern detection capability. By learning a small amount of defect data through a special algorithm, the inspection system can automatically learn and calculate other defect possibilities, allowing defect detection accuracy to reach over 97%. By observing the waveform, it can also detect vibration and even noise abnormalities, and quickly report the inspection results through the firewall-equipped Ethernet and private cloud, and display them on the Real-Time Situation Dashboard to realize 24-7 intelligent factory management.

With strong R&D drive and passion to serve customers, Chin Fong's Intelligent Forming Productivity Management System (iFPMS) solution for the stamping industry was recognized by the 29th Taiwan Excellence Award in 2020.

Exceptional customer service: Competitive advantage

Established in 1948, Chin Fong Machine Industrial Co., Ltd. is not only the largest mechanical press manufacturer in Taiwan, but also one of the top five manufacturers in the world. As a global leader in forming technology with total solution, Chin Fong understands that it is an important strategy to help customers build smart factories, enhance their competitiveness and bring new developments to the market. Therefore, Chin Fong analyzes users' experience and customer data collected by one year, and uses AI technology to find out the useful data for system optimization and then upgrade customers' system. Such close cooperation demonstrates the solid trust and satisfaction between Chin Fong and its customers.

To date, 100% of customers who have imported iForming have renewed their orders with additional features, which means that customers are really using this smart production model and found it extremely useful. In the future, by making the popular features standardized, Chin Fong will not only reduce the cost of implementation for customers, but also enhance the added value of the product and develop a customized solution for each customer.

Despite the rapid changes in the global market, what remains the same is that customers care most about product quality and service. In response to customers' remote maintenance needs, Chin Fong provides after-sales service via mobile device app, so the data is updated online with zero time difference. Today, Chin Fong is transforming from a manufacturing based industry to a service based "Manufacturing Service Industry", creating greater added value through integration of hardware and software.

Finally, the most important thing to remember any enterprise is that there are no results inside its walls. For Chin Fong, the result of a business is a satisfied customer. The goal is to have a customer service that is not just the best but legendary.

Video Link: https://www.youtube.com/watch?v=nGmYzseXeEI

For more information, please visit Chin Fong's Website: https://www.chinfong.com/en/index.php