ALFA: Redstone AC servo robot

ALFAROBOT has 33-years-experience in developing robots for injection moulding machines. The company has launched different series of models suitable for injection moulding machines from 50T to 6000T. Among them, the Redstone AC servo robot is full servo driven robot, which can be used for IML, metal part inserting and some other application required for high accuracy. The Redstone robot is used for showing the nut insert, with precision gear reducer box, the repeat precision is ±0.1mm. This is ideal for the production of home appliances.

Dongguan Alfa Automation Technology Limited

Tel: +86-769 8318 0326

Fax: +86-769 8318 0329

E-mail: info@alfarobot.com

Website: www.alfarobot.com

Booth: 11P41

ARBURG: Digitalisation & additive manufacturing

Arburg is focusing on digitalisation and resource conservation while other highlights include the Freeformer for the industrial additive manufacturing and a smart Allrounder in the “Factory of the Future”. The LSR version of an Allrounder from the Golden Electric series is being presented to the international trade fair scene for the first time. The exhibit demonstrates the production of demanding lenses for the automotive industry. Also on demonstration is the fully automated manufacturing of pipette tips. An Allrounder 470 H. A Freeformer 300-3X shows the combination of two components and support material to create a functional component, using a hard/soft combination.

ARBURG (Shanghai) Co., Ltd.

Tel: +86-21 6085 2188

Website: www.arburg.com

Booth: 10J21

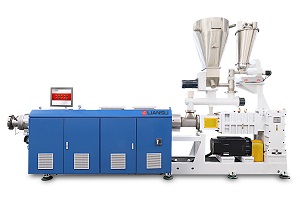

Bausano: Twin-screw extruders

The new MD Series of Twin Screw Extruders imparts greater durability, exceptional performance and great energy savings. The MD Plus and MD Nextmover twin screw extruder series are the most innovative solutions in the field of extrusion. The extruders feature screw geometry designed to improve efficiency; transmission system capable of reducing torque effort to a quarter improving performance and extending the life of the system latest generation motors and a valuable, intuitive tools for analysing consumption. Born from Bausano experience and the ongoing research of increasingly performing technologies and solutions, the new MD Plus and Nextomover extruders for plastic materials improve line productivity and reduce costs and energy consumption. Each extruder is unique, even different from the others belonging to the same series. What never changes is the ability to optimise production, cutting down costs and passing any tests with exceptional results.

Bausano & Figli S.p.A

Tel: +39.0124.26326

E-mail: info@bausano.com

Website: https://www.bausano.com/

Booth: 10G51

Brückner: BOPP film stretching lines

Brückner Maschinenbau presents its stretching line concepts with significant efficiency increases and for future recycling solutions. The high-speed, high-output BOPP film stretching lines are the widest, fastest and most productive within the industry - with speeds above 600m/min and hourly outputs over 8.5 tonnes. New line concepts for the production of BOPE films are also featured. The lines have the flexibility to produce BOPP films. The new inline coater for all BOPP and BOPE lines makes the production of extremely thin functional layers within the nano range possible. Due to the extreme thinness, the layers don’t disrupt the sorting and recycling, but cater, for example, for an improved adherence during metallising and excellent barriers in combination with aluminium oxide coating.

Brückner Maschinenbau GmbH & Co. KG

Tel: +49 8662 63-9278

E-mail: karlheinz.weinmann@brueckner.com

Website: www.brueckner.com

Booth: 10P23

Chen Hsong: All-electric injection moulding machine

SUPERMASTER SPARK series All Electric Injection Moulding Machine is designed to cater to a wide range of applications from ultra-thin-walled moulding (such as high-speed packaging) to thick-walled, high-pressure parts (such as optics). The machine is facilitated by a proper balancing of multiple, complex and even contradictory performance requirements. It features the Agile Boost Control technology that uses a proprietary ultra-high-response servo system to produce levels of responsiveness capable of going from 0 to 2000 rpm in less than 30 msec. The technology is faster than the traditional all-electric machines, and produces a shorter cycle, and higher precision injection and clamping actions for quality outputs. Moreover, a revolutionary Auto Stress Release System (ASRS) is employed to dynamically monitor the actual motion of the injection screw via high-speed digital pressure transducers and to make real-time adjustments to the screw motion.

The Chen Hsong Group

Tel: +852 2665 3222

E-mail: comm@chenhsong.com

Website: www.chenhsong.com

Booth: 12H41

Colines: MDO unit for films production

COLINES® has always been investing in its R&D department as it is totally aware that the flexible packaging market is strongly and constantly evolving. The company highlights the development of its MDO (Machine Direction Orientation) units. After focusing on the mono-orientation of CPP film, achieving a significant downgauging while creating better mechanical and optical features for the film, COLINES spent the last months developing innovative features of the mono-orientation of CPE film. MOPE offers amazing features, which could be crucial for creating a valid alternative to some existing products in various markets. Step by step COLINES® is getting the best results in this field, thanks to the ongoing developments of the MDO units.

COLINES spa

Tel: +39 032148 6311

E-mail: marketing@colines.it

Website: www.colines.it

Booth: H89

Davis-Standard: Total extrusion and converting solutions

Davis-Standard, LLC is set to market total solutions encompassing product capabilities and support services. Global aftermarket services and equipment technology for sheet, foam, blown film, thermoforming, pipe, profile and tubing, cast film, extrusion coating, and liquid coating are among the highlights. Specific to Asia, Davis-Standard’s high-output systems for medical tubing, cast film, blown film and extrusion coating have been essential to medical and packaging applications. Davis-Standard also features its dsX flex-pack™ 300S, a single station extrusion and lamination line.

Davis-Standard, LLC

Tel: +86-21 5407 1910

Website: www.davis-standard.com

Booth; 10R11

ENGEL: Digital solutions to injection moulding

ENGEL focuses on recent and upcoming trends as it takes part in the Factory of the Future exhibit. The all-electric and tie-bar-less ENGEL e-motion 80 TL injection moulding machine is equipped with many digital products from ENGEL's inject 4.0 program. While smart assistance systems from ENGEL's iQ series help plastics processors to leverage the full potential of the injection moulding machine, even if qualified personnel are not present at all times, digital service products are all about ensuring high productivity in order to remain able to deliver even in the event of a crisis. ENGEL is continually developing its smart assistance system portfolio. The latest products to be presented in Shenzhen include iQ process observer and iQ melt control.

ENGEL Machinery (Shanghai) Co., Ltd.

Tel: +86-21 5151 9292

Fax: +86-21 5151 9298

E-mail: info.cn@engel.at

Booth: Industry 4.0 – Factory of the Future, hall 11

Ever Polymer: TPE resin

With EVERLON as it main brand, Ever Polymer specialises in the development and applications of TPE. Four major application series — EVERMedi, EVERSeal, EVERPeel and EVERAuto — have been further created according to different professional fields, with the aim to satisfy the demands for global TPE markets in terms of the top four high-end application areas, namely medical devices, food packaging, commodity sector, and automobile parts. All materials complied with regulations association, such as REACH, Rohs, FDA and USP VI etc.

Ever Polymer Co., Ltd.

Tel: +886-3 312 5717

Fax: +886-3 312 5718

E-mail: Vincent.liao@everlon.com.tw

Website www.everlon.com.tw

Booth: 16R38

FCS: Intelligent manufacturing solutions

FCS Group presents its injection machines in the range of all-electric, multi-component and power saving. These are applied in various industries likes houseware, packaging, optical element and medical appliance. In addition to the FB series, all machines are electric-driven which shows the innovation of FCS electric injection technology. “iMF 4.0 Intelligent ManuFactory System” can be mounted on the injection moulding machines and use intelligent sensing modules to improve product yield and reduce production waste. It can be used regardless of the brand of the injection machine, so that the production manager can promptly grasp the production status, thus seizing the "intelligent" manufacturing opportunities for customers.

FCS Group

Tel: +886-6 595 0688

Fax: +886-6 595 1129

E-mail: fcsco@fcs.com.tw

Website: www.fcs.com.tw

Booth: 9B21

FIMIC: Automatic melt filter

FIMIC has 26 years of experience in designing and manufacturing of filter. FIMIC’s design of the filter is an innovation, entirely different from the melt filter in the market. The design of FIMIC filter is based on these ideas: Easy operation and maintenance, for different types of material and contamination, low operational cost, low melt loss, less worker needed, affordable spare part and flexible to work with different recycling extruders. FIMIC filter uses only one screen, punched screen or laser screen. Also, the filtration surface is very large compared to other filters on the market. The common issue for the melt filter on the market is too sensitive, the aggressive contamination could damage the parts on the filter and increases spare parts cost to the recyclers. FIMIC filter avoids this sensitivity on the mechanical parts, but to keep the high performance of filtration ability.

FIMIC SRL

Tel: +39 049 595 71 63

Fax: +39 049 595 80 96

E-mail: sales@fimic.it

Website: www.fimic.it

Booth: 10E71

Fomtec: Screwdriver & tool automation production line

Fomtec Plastic Machinery is presenting alternate die cores, which are connected to the turret structure of the machine. By rotating the turret, the die core is moved from one mould to the other for secondary moulding of the product. The product extension, through two types of models, product 1 and product 2 are combined for installation to reach the final products required by customers and realise the automation process. The company has also overcome the automation difficulties with its screwdriver which enables improvement in the visual system and automation. It has also been able to integrate injection moulding machine with automatic production line to reduce labour costs.

Fomtec Plastic Machinery (Guangzhou) Co.,Ltd.

Tel: +86-139 2886 9836

Fax: +86-20 3685 0100

E-mail: os@fomtec-group.com

Website: www.fomtec-group.com / www.fomtec-vimm.com

Booth: 11A5

Forwell: Quick mold change system

Forwell’s Quick Mold Change System includes mould clamps, a control box and a power unit. The system is ideal for injection moulding machine/die casting machine, where the benefits include: reduced die change time; diverse products in small lots; reduced inventory; improved productivity and quality; reduced labour costs, among others. The Quick Mold Change System is controlled by hydraulic, which makes it safe and easy to operate.

Forwell Precision Machinery Co., Ltd.

Tel: +886-4 834 5196

Fax: +886-4 834 5197

E-mail: p02@forwell.com.tw

Website: www.forwell.com

Booth: J901

Guangdong Blesson: Single screw extruder

The BLD50-40 Single Screw Extruder features the latest design of large L/D ratio, good plasticisation and dispersion with high output. It has an optimised spiral grooving feed bush design, with high efficient material feeding, and WEG permanent magnet synchronous motor, high efficiency and energy saving, low noise operation. The extruder is installed with Taiwan-made gearbox, Siemens 12” Touchable Screen Operating System and iNOEX Gravimetric System, heater with insulation for fast heating and energy saving operation. Electrical parts include ABB inverter, ABB or Schneider contactor, ABB or Schneider breaker, CELDUC or CRYDOM solid state relay.

Guangdong Blesson Precision Machinery Co., Ltd.

Tel: +86-760 8850 0303

Fax: +86-760 8850 0303

E-mail: info@blesson.cn

Website: www.blesson.cn

Booth: 6B01C

Guangdong Costar: Extrusion line

The SJ75/85/75-2200 LDPE 3-Layer Film Extrusion Blown Machine includes the Syncro brand 6+6+6 dosing unit and auto thickness control air ring. It is integrated with Taiwan-made die head, B+R system control, rotary tower take up, and central gap type winder. It is suitable for food, medical, chemical industry and other applications.

Guangdong Costar Machinery Technology Co., Ltd

Tel: +86-760 2397 6181

Fax: +86-760 2397 6180

E-mail: sales@costar8.com

Website: www.costar8.com

Booth: 5L41

Guangdong Liansu: Flexible industrial control system

Guangdong Liansu Machinery Manufacturing Co., Ltd. presents at Chinaplas 2021 its flexible industrial control system based on FLEXCON+ equipment control+data interconnection that is specially developed for plastic extrusion production line that is integrated with PLC control system and information PC system. The two systems run at the same terminal at the same time, making it possible the high integration of program control, data acquisition and analysis.

Guangdong Liansu Machinery Manufacturing Co., Ltd

Tel: +86-757 2388 8340

Fax: +86-757 2388 8558

E-mail: info@liansu.com

Website: www.ls-extrusion.com

Booth: 8F45

HRSflow: Cylinder

The new S Series Cylinder is now available: the new compact solution by HRSflow allowing a reduced pitch and suitable for technical materials. It provides several benefits for customers. Firstly, thanks to its compactness, the plate thickness can be lowered; and secondly, its reduced width allows for a minimum nozzle pitch of 37 mm (1.46 in) in order to meet two main market needs: compactness and accuracy. Suitable for the production of technical and electronic parts and consumer goods, it is the ideal solution for small shot-weights and multicavity applications.

HRSflow, member of INglass

Tel: +86-571 8668 6999

Fax: +86-571 8668 6901

E-mail: grace.huang@hrsflow.com

Website: www.hrsflow.com

Booth: 14G41

Jiangsu Victor: All electric injection blow moulding machine

All electric injection blow moulding machine is Jiangsu Victor’s breakthrough in green energy. Each mechanical action of this machine is driven by servo motor. Compared with hydraulic injection blow moulding machine, it has the following advantages: 40-50% energy saving than hydraulic machine (depending on product); clean and low noise, meet customer's special requirement on cleanliness; wide speed control range and good responsiveness; high precision and repeatability; improved the forming efficiency of products. Also featured is the MSZ30 in - mould labeling technology.

Jiangsu Victor Machinery Co., Ltd

Tel: +86-512-58921216

Fax: + 86-512-58441012

E-mail: sales@victorcn.com

Website: www.victorcn.com

Booth: 4B21

KRAIBURG TPE: TPEs for automotive

The multi-faceted benefits of THERMOLAST® K TPE compounds from KRAIBURG TPE are widely approved by major automotive OEMs for exterior and interior automotive applications. THERMOLAST® K TPE compounds feature excellent weather resistance, UV resistance and extremely good, cost effective processing. They also enable you to create visually attractive and high-quality surface for the exterior applications. In automotive interiors, TPEs assure surfaces are attractive and feel good to the touch. They improve soft-touch elements as well as reduce annoying rattling and creaking noises when used for damping elements.

KRAIBURG TPE Technology (M) Sdn Bhd

Tel: +60-3 9545 6393

E-mail: Info-asia@kraiburg-tpe.com

Website: www.kraiburg-tpe.com

Booth: 17A31

MAAG: Pump and filtration systems

MAAG Group is a broadly diversified global solutions provider of Pump & Filtration Systems, Pelletising & Pulverising Systems, Recycling Systems and Digitalisation for use in the polymer industry. Its ERF350 is a high-performance melt filter for the filtration of heavily contaminated polymer feedstock while its PEARLO® underwater pelletising system is ideal for the highly efficient and flexible production of spherical pellets with throughputs of up to 36,000 kg/h. The BAOLI®-3 is the third-generation dry-cut pelletiser for processing hard and soft materials, while extrex® gear pump in x6 class design are also featured.

Maag Pump Systems AG

Tel: +41-44 278 8200

E-mail: welcome@maag.com

Website: www.maag.com

Booth: 10Q01

Malex: Air bubble film machine

Malex high speed 5 layers (1600mm) air bubble film machine has a maximum running speed of 38m/min with 25g square metre. The machine adopts scientific design, double chilled water cylinder which improves the better cooling of silicon rubber roller, and helps the machine runs faster. Bubble forming cylinder is designed with double-direction cooling system for better bubble forming effect. Automatic cutting winder is good for labour cost saving with high output.

Malex Plastic Machinery Co., Ltd.

Tel: +86-757 2280 1782

Fax: +86-757 2280 1783

E-mail: info@malexco.com

Website: www.malexco.com

Booth: 5P51

m-hub: Global mobile app

m-hub is the first global mobile app for the plastic industry. The company aims to connect all the plastic supply chain through an all-around platform tailor-made on the needs of the industry by leveraging mobile technologies. The mobile app which aims to brake barriers and to support plastic professionals take a step towards a digital future.

m-hub S.r.l.

Tel: +86-188 5811 0893

E-mail: support@m-hub.com

Website: https://app.m-hub.com/cn

Booth: 14J27

Moretto: Auxiliary equipment

Moretto presents its exclusive gravimetric dosing unit, DGM Gravix, which is a robust, precise and unbeatable machine that ensures complete production flexibility and the highest precision levels even in presence of vibrations. X Comb is a compact and full electric mini dryer that ensures perfect polymer’s dehumidification thanks to the homogeneous treatment of the material inside the exclusive OTX (Original Thermal eXchanger) hopper, which solves the problem of falling flows to guarantee uniform dehumidification in a shorter time.

Moretto Marketing Office

Tel: +39 049 9396711

E-mail: marketing@moretto.com

Website: www.moretto.com

Booth: 10F41

SACMI: Cap manufacturing solution

With a market share of over 75% in China, SACMI is the country’s leading provider of plastic cap manufacturing solutions that use compression technology. Hence, SACMI presents its complete range that integrates the cap slitting and folding solution with in-line slit quality control. Advanced in-line controls at every stage and technological leadership in the manufacturing process allow SACMI to excel, offering the best solutions on the market to respond to the latest packaging-closure trends from a lightweight and integrated neck-capsule design perspective. Also on display is the SFM slitting solution for an AB 1881 COOL+ cap for CSD applications.

SACMI

Tel: +39-0542 607111

Website: www.sacmi.com

Booth: 10G41

Shantong MengXing: Thermoforming machine

The new generation of high-capacity thermoforming machine MFC9070 has a large forming area of max. 900mm*700mm. The mould locking force is 80 tonnes, cutting force is 90 tonnes. The forming mould is more flexible and it can be installed with servo plug assist. The forming station has the Gate Cut in Mould function to help customers to cut the cost. The stacking station contains multi-function features. Depending on different needs of different customers, downward stacking or manipulator stacking are both available.

Shantou MengXing Package Machinery CO., LTD.

Tel: +86-156 2675 1890

Fax: +86-754 8858 4033

E-mail: Mx1@stmengxing.cn

Website: www.stmengxing.com

Booth: 5A31

Shini: Dual-purpose water/oil heater

STM-W/O series dual-medium mould temperature control units are used as mould heaters to maintain mould temperature. The unit can be used in other similar applications, which can use water or heat transfer oil as the heat transfer medium for different production processes or conditions. Unit also has multiple options and accessories to meet various production process needs, such as a flow meter, manifold, hose, multi-coupling system, etc.

Shini Plastics Technologies, Inc.

Tel: +886-2 2680 9119

Fax: +886-2 2680 9229

E-mail: Shini@shini.com

Website: www.shini.com

Booth: 12M41

SI Group: Additives

SI Group, a global leader in the innovative technology of performance additives, process solutions, active pharmaceutical ingredients, and chemical intermediates presents its new advancements in plastic additives technologies and its rubber and chemical intermediate solutions at Chinaplas 2021. SI Group’s newest innovations including WESTON™ 705, ULTRANOX™ LC, and NAUGARD™ E-1 antioxidant and stabilisation solutions.

SI Group – Shanghai Co., Ltd.

Tel: +86-21 2422 9200

Fax: +86-21 2422 9300

Website: www.sigroup.com

Booth; 15D39

Sikora: Measuring, control, inspection systems

For online inspection and sorting of plastic material, SIKORA showcases the PURITY SCANNER ADVANCED. The system uniquely combines an X-ray with up to three optical cameras. For a 100 % quality control during the extrusion of pipes, SIKORA exhibits the CENTERWAVE 6000, a system based on millimeter wave technology. The device precisely measures the diameter, ovality, wall thickness, the inner profile as well as the sagging of the pipe. The X-RAY 6000 PRO measures the wall thickness, eccentricity, the inner and outer diameter and the ovality of hoses and tubes.

SIKORA AG

Tel: +49-421 48900-0

Fax: +49 421 48900-90

E-mail: sales@sikora.net

Website: www.sikora.net

Booth: 10G05

SOREMA: Recycling plants

SOREMA div. of PREVIERO N. SRL, offers a wide range of solutions including systems for cold/hot/chemical washing, pre-washing, material and colour sorting, wet grinding, drying, conveying and storing, continuous agglomeration and extrusion. Upon request Sorema can also offer modules for the up-grade of existing plants. Flexibility is given by the wide capacity that its plastic recycling machines can achieve.

SOREMA, div. of Div. of Previero N. srl

Tel: +39 031 63491 250

Fax: +36 031 63491 217

E-mail: sales@sorema.it

Website: www.sorema.it

Booth: 10E41

Tung Yu: Injection moulding machine

FIFO Injection Moulding Machine from Tung Yu has stable output and synchronisation by four injection cylinders design with double open side movement. The vertical structure is designed with screw, piston and barrel in line to have straight compound flow with less pressure loss. The FIFO design with latest compound injection yields stable product quality. Also, there is less remnants in feeding tube, which could save compound in purge. The multi-stage pressure control system and accurate compound calculation are appropriate for injection moulding variants.

Tung Yu Hydraulic Machinery Co., Ltd.

Tel: +886-49 225 3588

Fax: +886-49 225 2998

E-mail: tungyu@tungyu.com

Website: www.tungyu.com

Booth: 8F23

WM Thermoforming: Thermoforming machines

Real-time visit of the WM Thermoforming plant plus live demonstration of the thermoforming machines are highlights. The machines available for display in WM’s facilities include the FT and TWIST range (in-mould trimming with lower tilting platen), FC range (vacuum and pressure thermoforming machines with steel rule die cutting), and the FLEX92 (steel rule cutting machine with extensive mould matching).

WM Thermoforming

E-mail: sales@wm-thermoforming.com

Website: wm-thermoforming.com

Booth: 10K43

Wutung: UV curing & screen printing system

The Automatic UV Curing & Screen Printing System, CA-102, is designed for high volume single to multicolour screen printing, specially designed for round, oval and rectangle container or other special products. It is widely use on cosmetic, food products, beverages and more. The Screen Train is equipped with semi-auto loading system, tailor made automatic feeding system can also be customised. According to different printing package requirements, automatic labeling and hot stamping system can be installed.

Wutung Trading Co., Ltd.

Tel: +852 2426 9761

Fax: 00852-24890968

E-mail: roy@wutung.com.hk

Website: www.wutung.com.hk

Booth: 11P21

ZAMBELLO: Co-rotating gearbox

The Co-Rotating Gearbox – TST SERIES from Zambello responds to the needs of manufacturers who want to increase the power rates of co-rotation twin screw extruders. The TST (Twin Super Torque) Series is provided with a torque distribution system which is able to ensure a considerable increase of the output revs. (up to 1800 rpm.) and of transmissible torque density (up to 16 Nm/cm3 per shaft). The dimension of the gearboxes of the TST range available at present go from centre distances of 21.5 mm to 120 mm.

ZAMBELLO group- Asian Marketing Office

Tel: +886-7 614 1119

Fax: +886-7 614 1120

E-mail: service@zambelloasia.com

Website: www.zambelloasia.com/zambello.php

Booth: 10Y23