By: Kathryn Gerardino-Elagio

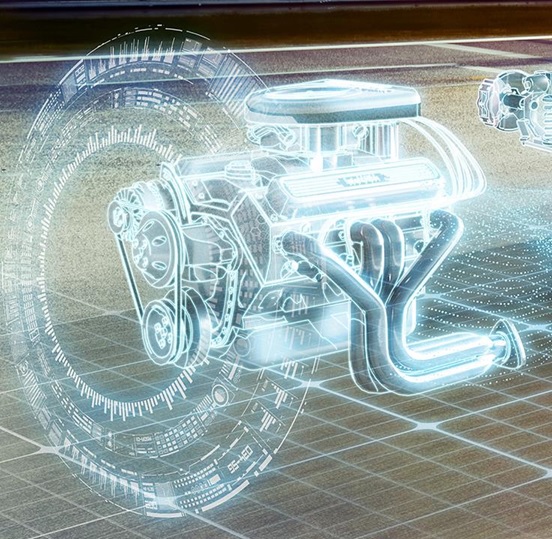

There is a lot of buzz about digital twin. Everybody defines it differently, and a quick search will generate a dozen results and definitions. Today, most of the definitions of digital twins are typically from vendors. Each creating their own definition to highlight their focus and perceived competitive advantage. Some definitions of digital twin include: a connected product, a 3D design or simulation model of a product – things Siemens Digital Industries Software has been doing for years.

During the 2020 Siemens Media and Analyst Conference, Stuart McCutcheon, Global Vice President Global Sales and Customer Success, discussed how digital twin can help drive innovation and business value, and how Siemens broad solution offering can provide the most comprehensive digital twin.

Stuart McCutcheon

According to Stuart, there are some business challenges customers are solving with digital twin. They invlove: shortening the overall design and manufacturing lifecycles, while managing increased product complexity; being more responsive to changes in market demands –from product volume changes to product mix or to a sudden need to start making a brand new product like what Vinfast did with our help, switching to designing and making ventilator in weeks.

“As you look through the many definitions, there are a couple of common characteristics. The digital twin is a virtual representation of a physical object. Like the physical object, it evolves over time with changes. This is the basic definition of the digital twin,” he explained.

What is a digital twin?

“At Siemens, our definition and understanding is of a more comprehensive digital twin that has more precise characteristics. Some believe that there are multiple digital twins for a product. Our perspective is there is only one digital twin for a product that includes and supports numerous lifecycle phases along with the respective representations and models of physical behaviour. This concept is important to understand when we describe the characteristic of a comprehensive digital twin,” Stuart remarked.

Siemens view of a digital twin is that it must be comprehensive and have these characteristics: 1) Precise virtual representation that matches exactly the physical product configuration or process flow and steps at any point in time. 2) It participates across the lifecycle to simulate, predict and optimise the product or production system. 3) As a product gets more complex, it requires more complex models to define its behaviour. So the complexity of the digital twin is directly connected to the complexity of the product.

A product has one digital twin, with multiple supporting representations, views or models. A complex digital twin can include models, CAD, CAE, software binary, ECU, wire harness models, the released BOM and so on.

He explained that a digital twin evolves over time, just like a product, with configurations, versions and inter-relationships. A closed-loop digital twin provides an integrated feedback system to validate, compare, optimise and even control behaviour by directionally between the physical product and its digital twin –such as a Windmill on a remote hilltop sending sensor data and gearbox, and to drive a simulation model that can predict the performance and wear of the gearbox.

What makes Siemens credible?

Siemens is credible to deliver the most comprehensive digital twin because of its deep and broad software portfolio, the Xcelerator portfolio, which they are able to deliver the industry’s most comprehensive digital twin.

The company provides solutions that span the complete lifecycle, cross domain understanding of data and configuration management across the virtual and physical worlds.

Stuart stated, “We are a leader in process automation, which we combine with deep multi-industry and domain knowledge, as a manufacturer – so not only do we make the software, we use it ourselves. We have a long history of connecting the virtual and physical worlds.”

“The Mendix low-code app development platform is making it easier than ever before to leverage and expose data inside the digital twin,” he added.

Dimensions of comprehensive digital twin

The comprehensive digital twin has different dimensions and level of complexity based on the complexity of the physical product it is twined with, such as: digital twin lifecycle; digital twin cross domains; depth of modelling simulating a digital twin cross domain cross lifecycle; change management and configuration of simulation model to model to asset; closed loop digital twin; and complexity of high volume assets.

Stuart revealed, “The first dimension we consider is industry & industry segment. Each have different characteristics & business drivers. High-tech companies have rapid design cycles and produce high volume of products and relatively short customer lifecycle. Shipbuilders take years to design and manufacture a single product for as long as 10 years that will be in service, and maintained for decades. Therefore when we look at where digital twin can bring value, we always look at it from an industry perspective working out where we can bring the largest value.”

Teamcenter manages the massive amounts of virtual life cycle data, the versions and configurations of data throughout the lifecycle and manages the relationships between information, such as design, (mechanical electrical software), simulation, and manufacturing service all under change control.

MindSphere – the company’s Industrial IOT solution - connects to the physical products/assets, collecting and managing information from these assets, such as time series data streams collected from sensors. Across the Xcelerator portfolio, there are solutions that can leverage data from both these domains and forma a closed loop digital twin along the lifecycle. The closed loop digital twin allows a company to closely connect the physical products to the virtual models and correlate real world behaviour with virtual simulation models. This improvise the accuracy of the simulation model, which in turn can be leveraged to optimise the product design.

He mentioned, “For the purposes of the cross industry framework, we simplify the digital lifecycle down to three key stages: design, manufacturing and service; and this simplified view is applicable across nearly all industries.”

Summary

Stuart said, “Digital twin provides real business value and you can start at any point of the lifecycle - in product design, on factory floor or in the field. The Siemens digital twin provides the most comprehensive set of capabilities and integration across the lifecycle domains.”

Product digital twin helps navigate complex systems and materials by allowing the building of product twins from hierarchical layers of related models (e.g., electrical, mechanical, thermal, energy, etc.) that supports individual analysis and as an integrated system of systems. The closed-loop digital twin provides the ability to feedback real-world data into the virtual representation to refine and optimise.

Digital twin enables the individual process stages to be seamlessly linked to create a consistent interconnected set of models and in-context data. The best practice is connecting the digital twin with its physical pair, keeping them in sync and traceable over their lifecycle, including changes in configurations, versioning, revisions, servicing, location changes, and data and system interconnections.

“The best practice is connecting the digital twin with its physical pair, keeping them in sync and traceable over their lifecycle,” he finally added.