A new tool grinding technology process is currently being developed to reduce excessive non-productive times and increase productivity in tool production. It is based on work carried out by Dr.-Ing. Mirko Theuer of the IFW (Institute of Production Engineering and Machine Tools, Leibniz University of Hannover) for his dissertation. The resulting new generating grinding process holds enormous business and scientific potential.

The peripheral cutting edges of drills, end mills and other rotationally symmetrical cutting tools are usually produced by a sequence of different grinding processes. However, each grinding operation, e.g. for the rake and flank face, requires different grinding tools. This requirement in combination with the necessity to consecutive machine the different cutting edges of the cutting tool result in high non-productive times due to frequent idle movements of the machine and the grinding tool changes.

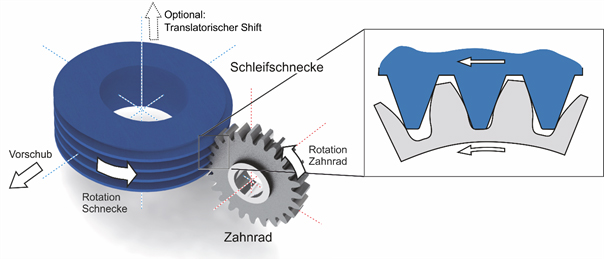

At the Institute of Production Engineering and Machine Tools (IFW) of the Leibniz University Hannover, a new tool grinding process has recently been developed in order to address the mentioned challenges and increase the productivity during tool manufacture. The process kinematics of this process are similar to the continuous generating grinding process of gears (Figure 1), which has been established for the hard fine machining of gears in the last century due to its high productivity. In addition to an increased process productivity, its improved manufacturing quality (e.g. pitch accuracy) compared to competing processes such as discontinuous profile grinding was particularly decisive for this development.

Figure 1: Process kinematics of a continuous generating grinding process

For a long time, however, the generating grinding process was not suitable for the production of the strongly asymmetrical and undercut tooth geometry of cutting tools. Therefore, it has exclusively been used for the machining of gears in the past. In order to produce an asymmetrical cutting tooth geometry with sharp cutting edges for a cutting tool instead of the involute of a gear tooth, specific process modifications had to be made. For example, the geometry of the grinding tool (grinding worm) and the process parameters were influenced in a specific manner so that the undercut cutting edge of end mills and drills can be produced. As a result, the process allows the simultaneous machining of all peripheral geometry elements of a cutting tool in one step. This means that all rake and flank faces are manufactured in a single process step and with a single grinding tool.

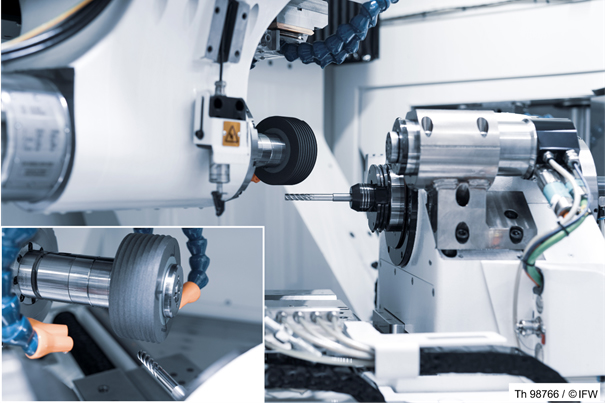

The further development of the process included simulations of the grinding process in order to identify fundamental relationships between the process parameters, the grinding worm geometry and the target geometry of the cutting tool. Based on this knowledge, the IFW succeeded in deriving a design methodology for the targeted adjustment of the geometry of the cutting wedge. This methodology makes it possible to determine suitable process parameters and grinding worm geometries for producing a required cutting edge geometry of the cutting tool. Following these theoretical process considerations, a generalized derivation of the axis couplings required for the process was performed. This is necessary to make the process applicable not only on continuous generating grinding machines, but also on conventional machines used for cutting tool production (Figure 2). To verify these couplings, a cylindrical grinding wheel was profiled with a grinding worm geometry that was determined in the simulation and then used to grind end mills made of high-speed steel.

Figure 2: Continuous generating grinding of cutting tools

These advances allowed to demonstrate the practical usability of the process on commercially available tool grinding machines. When investigating the quality of the ground cutting tools it was found that, despite the very early stage of development of the grinding process, the geometric quality and cutting edge quality of the produced cutting tools are already on a similar level with conventionally ground tools. An additional study has shown that process times comparable to the state of the art can be achieved in the manufacture of milling tools. However, a very high optimization potential with regard to the new grinding process remains to be exploited in the future. For example, in contrast to the very well researched conventional tool grinding process, neither an optimization of the process parameters, the coolant supply nor the grinding tool specification has yet been carried out. In addition, there are process-specific productivity advantages which, in the new generating grinding process, result from the use of multi-start grinding worms or shift movements. Those advantages can significantly increase process productivity and are technologically not applicable to conventional tool grinding process: The shift movement (Figure 1) enables new sections of the grinding worm being continuously engaged during grinding. This may be used to compensate the occurring grinding tool wear and to keep the high production quality constant, even in large-scale production. However, the ideal utilization of this potential is still being researched at IFW, as is the use of multi-start grinding worms, which can lead to a multiplication of the process productivity.

In final investigations the manufactured cutting tools were used in a milling process in order to compare their performance to conventionally ground end mills. In these tests, it was found that the service life of the milling tools can be increased by up to 15% if the newly developed continuous generating grinding process is utilized. The substitution of the conventional tool grinding process by the newly developed generating grinding process thus represents an immense economic and scientific potential that can be further exploited in the future. In addition to the already mentioned advantages, the possibility of manufacturing unequally pitched cutting tools by continuous generating grinding will be investigated. This will allow to produce all milling tool geometries that are relevant to industry with the new manufacturing process. Furthermore, all findings obtained in the recent studies can be transferred to the manufacture of other rotationally symmetrical cutting tools like drills, saw blades, disc cutters and reamers. The economic and technological advantages of the new continuous generating process can thus be transferred to a wide range of other applications.

The authors would like to thank the German Research Foundation (DFG) for financially supporting the research project "Continuous generating grinding of cutting gears 2" (grant number DE 447/153-2).

Source: Kontinuierliches Wälzschleifen von Zerspanwerkzeugen, Disseration, Mirko Theuer IFW 02/2020, 29.04.2020 (ISBN 978-95900-441-1)