Businesses today attach the term sustainable to products and activities ranging from fish and furniture to energy consumption and architecture. Their stated focus is on preserving natural resources and protecting earth’s environment. In a more narrow sense, however, machining in manufacturing has always pursued a form of sustainability. Machining competitively priced, high quality products enables a manufacturer to make a profit and thereby sustain its existence as a business.

Throughout history, manufacturers have sought ways to make their machining processes more efficient and cost-effective. Those efforts involve ongoing development of advanced and precise production machinery, improved cutting tools and optimisation of cutting systems overall. Specific strategies include high speed machining, high feed machining, high-performance machining and digital machining.

The recent initiative called sustainable machining aims at reducing raw material consumption, energy use and generation of waste throughout the product life cycle to a level that at least is in balance with the carrying capacity of our planet. Oftentimes, general discussion of sustainability concentrates on large global environmental issues but overlooks the basic elements of price, cost, customer satisfaction, process knowledge and reliability. When it comes to sustainability in machining, true success starts with simple, straightforward steps and analysis.

Sustainable pricing

Every business faces the challenge of setting sustainable prices for its goods or services. The price must be high enough to cover costs and produce a profit, but low enough that it doesn’t drive customers to competitors. A manufacturer can set a higher price if the customer perceives that the product provides sufficient value for what is paid.

On the other hand, if pressure from customers and competitors results in setting the price too low, profit margins suffer. When the price is below the cost of producing the product, losses result. If competitive pressures push the price too low, those designing and machining the product have to find ways to produce it cheaper, faster and better to cut production costs and support a sustainable profit margin.

Invisible costs

However, in many businesses the point where costs stop, and profits start is unclear. That is because the real costs themselves also are unclear. Hidden, ignored or unknown factors are not part of the cost calculation. Typical invisible costs include unplanned downtime, rejected workpieces and broken tools. These costs are not considered representative or “real.” The attitude or mindset that results in some cost factors becoming invisible is not limited to production staff; it can exist company wide.

Achieving a sustainable cost structure requires making the invisible visible. Manufacturing staff must examine and evaluate the machining process as well as the structure and flow of the organisation’s activities overall to uncover hidden costs.

Customer satisfaction

Customer satisfaction is a key element of economic sustainability. A customer wants to know when his or her order will arrive. Lead time, in a customer’s mind, begins when they place an order. And lead time is not exclusively production time. If machining a part involves three weeks process time, but administrative activities eventually take another two weeks, a shop must be honest with itself and its customers and state a lead time of five weeks. Metalworking equipment suppliers including Seco Tools provide tool inventory management, tool identification and machine monitoring systems that enable shop personnel to track customer jobs and maximise a shop’s ability to meet lead time goals and maintain customer satisfaction. (See sidebar)

Waste and measurement

Efficient manufacturing minimises wasted time, energy and raw material. Issues surrounding the waste products of machining such as chips, cutting oils and coolant are complex. Manufacturers traditionally consider the waste products as an unavoidable result of the process and believe that change is difficult to accomplish and, thus, has been minimal. The attitude in much of the machining world is “that’s how it goes, it’s just something to deal with.”

Effectively minimising waste and preserving resources requires thorough understanding of workpiece material characteristics and machining processes. Gaining that understanding involves accurate measurement of process factors to determine exactly what is being done and what the results really are. True accuracy avoids the use of round figures; round figures usually indicate incomplete knowledge of the process at hand and hinder valid determination of results when changes are made. If a shop claims its manufacturing efficiency is “above 60%,” is that 61% or 95%? Both are above 60%. Similar, cutting speed described as “around 200 m/min” is not trustworthy information. The speed more likely will actually be 195 m/min or 206 m/min than an estimated round number.

In one case, a shop owner was convinced that his facility utilized 70% (round number) of the time available for machining. Careful measurement determined that actual utilisation was only 34%. In simplified terms, among every three machines in that facility, one would be working, and the other two were idle. So, the shop owner’s undisciplined measurement (guessing) proved basically worthless.

Salary and sustainability

In analysing sustainability in relation to global labour costs, assessment of labour productivity should exclude salary costs. Labour productivity equals production turnover, minus the costs of purchased goods and services, divided by the number of employees, divided by a unit of time.

This formula measures labour productivity without influence of labour costs and enables valid comparisons of labour productivity among countries or businesses with differing salary scales. The salary of a skilled machine operator in a Western nation, for instance, may be ten times that of an operator in a lower-salary country, but that difference doesn’t indicate actual productivity. It is possible that the 10 operators in a low-salary country produce fewer parts, at lower quality, than the one operator in the West.

However, if actual labour productivity (as measured above) in the lower-salary country is at the same level as the Western country, then achieving economically sustainable productivity in the Western country requires investment in innovative technology and production methods and continuing education of manufacturing staff.

High labour productivity indicates that manufacturing personnel possess thorough insight into what they are doing and have comprehensive knowledge and skills. This enables them to work faster, realise their full competence and gain higher job satisfaction. For a skilled operator, machining is frustrating when unanticipated events occur. That happens frequently in today’s high mix, low volume production scenarios as the products and small lot sizes change very quickly. However, skilled, multi-disciplined operators can rapidly adjust operations to overcome bottlenecks and other disruptive events.

Reliable process

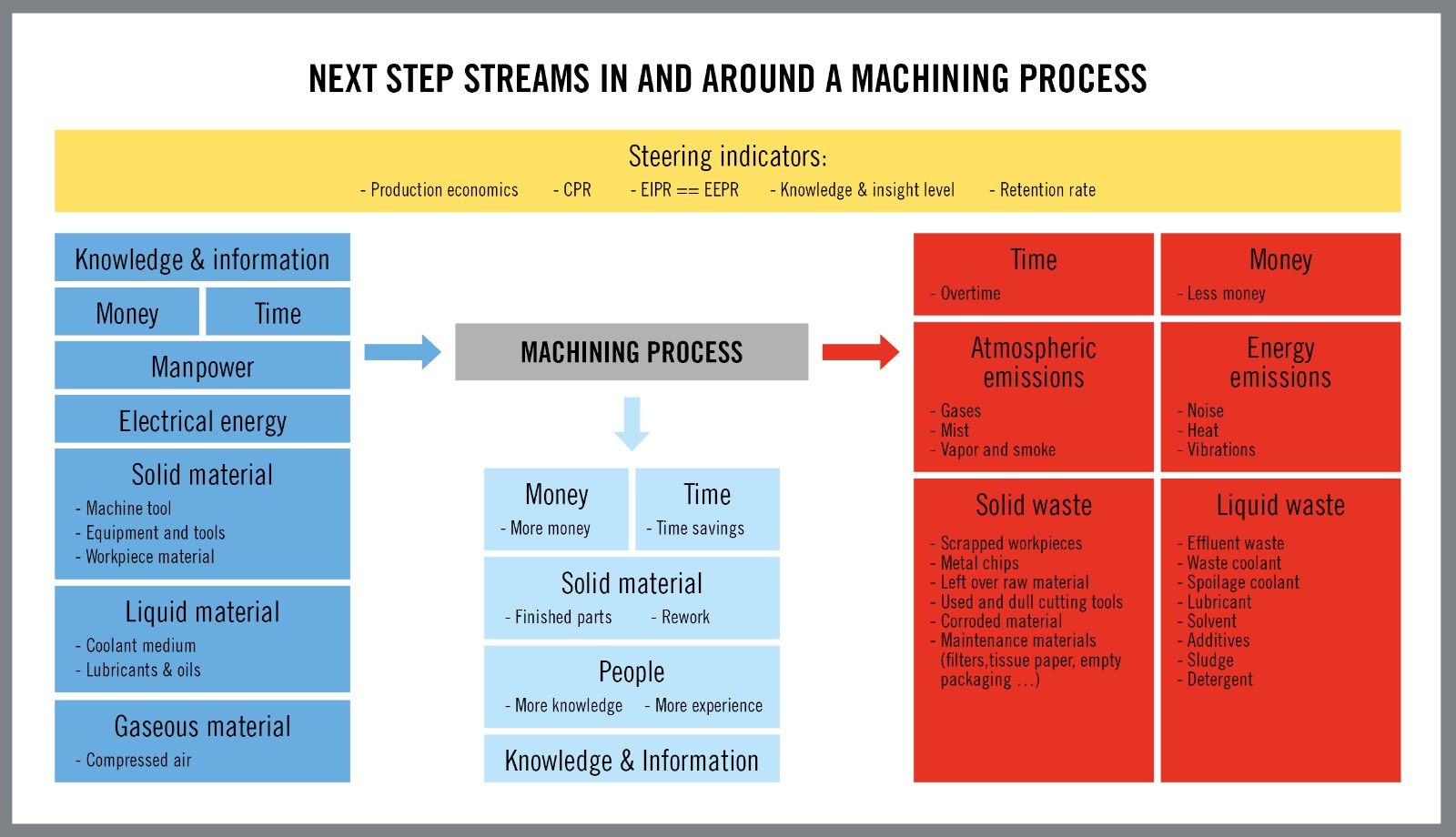

A sustainable machining process is reliable and predictable and minimises energy waste. An unreliable process results in reworked or scrapped workpieces and waste of the raw material, energy and labour used to produce the rejected work.

Similarly, from a sustainability perspective, work in process (WIP) is essentially waste. From an economic point of view, WIP represents lost money, lost time and wasted floor space. In addition, there is always the possibility that a stored semi-finished workpiece can be damaged as it moves through the logistics system. Accordingly, a shop should have as little WIP as possible.

Reducing energy consumption

Throughout history, manufacturing has found ways to accomplish greater results with less energy. For example, in the beginning of the 1980s many workshops had machines with 70 or more kilowatts of power. Today, milling machines with 7 kilowatts of power provide productivity that can be higher than that of those machines ten times more powerful. A sustainable machining process minimises energy consumed per cubic mm or cubic inch of material removed. Minimising energy consumption automatically results in less wasted energy, making machining a more environmentally friendly operation.

Maximising efficiency

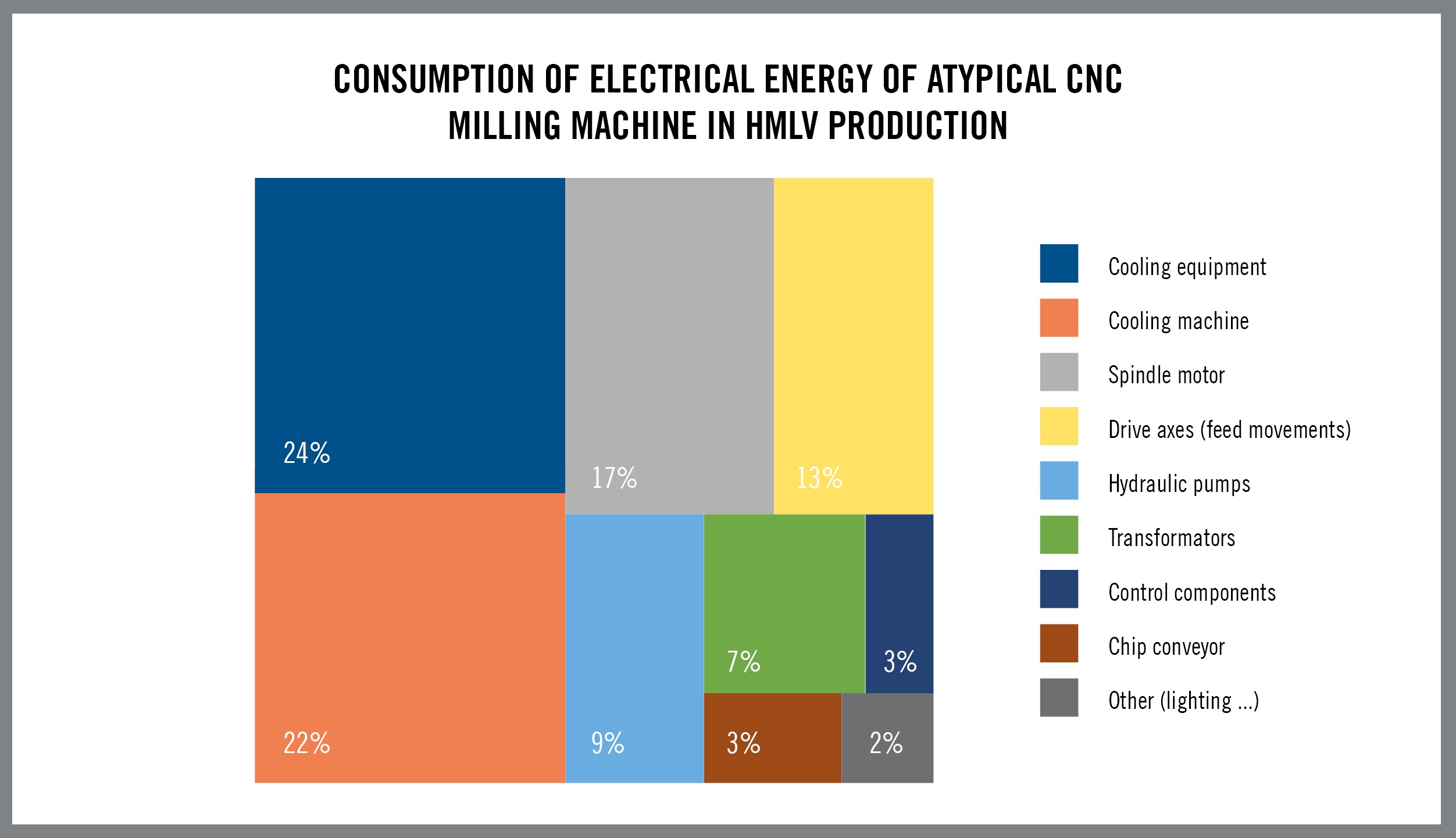

Figure 3 shows electrical energy consumption by a five-axis machining centre for one working day. (These data were gathered from just one machine and represent a general reference.) Surprisingly, the main spindle does not consume the majority of the energy the machine uses. The main spindle and axis drive motors typically use only 30 % of the energy, while various cooling systems employ 44 %, and pumps, transformers, machine control and other systems consume the rest. Consequently, when the machine is not cutting, most of the machine’s other systems continue to use energy.

Efficient use of energy can significantly boost product output with minimal increase in overall energy usage. In one scenario, actual machining of a part takes one hour. If programming, setup and waiting time require six hours, the machine will produce two parts in an eight-hour day. When the machine is cutting, energy consumption can be considered to be 100%, or nominally one unit. The cutting operation uses 20% of the energy, so when the machine is not cutting it consumes 80% of an energy unit. Therefore, total energy consumption for the day is 6.8 units while the machine produces two parts.

A second scenario follows analysis of the process with special attention to eliminating wasted time. The analysis enables idle time to be reduced to 5 hours, a cutback of 16.5%. Now three hours of cutting time are available, permitting the production of three parts. Total energy consumption per day is 7 units, or 3 % more than in scenario one.

Producing one workpiece in scenario one requires 3.4 energy units, while in scenario two, production of each workpiece requires 2.2 units of energy. Energy consumption per workpiece in scenario two decreases 36% on only a 3% increase in daily energy consumption. Producing three workpieces in scenario one would require the machine to run longer and consume more energy. Sustainable machining is not necessarily about consuming less energy, but it is about doing more with the energy consumed.