The COVID-19 pandemic continues to affect the global economy. There are more than 20 million cases recorded around the world, and death toll of more than 730,000 people. With no vaccine available, the medical sector is hard pressed to meet the challenges of providing much-needed services. In this aspect, the role of plastics become more important, as critical medical supplies, are made of plastics.

The virtual conference “Global Epidemic Control: Challenges and Opportunities for Medical Plastic Manufacturing” was organised by Ringier Events on 22-23 June and was attended by experts in the plastics industry dealing with medical packaging, high performance materials, advanced processing technology, and industry association representatives. One presentation was that of EMS-GRIVORY Asia, a business unit of EMS Group, represented by Mr. Andre Sutter, Key Account Manager, Industry, on Grilamid TR HT 200.

EMS-GRIVORY, a business unit of EMS Group, is a multinational company headquartered in Switzerland with its regional headquarters in Asia located in Suzhou, China. As a leading manufacturer of polyamides, EMS-GRIVORY offers an abundant range of polyamide products worldwide. Customer-oriented with strong focus on application development, the EMG-GRIVORY team is able to coordinate and support any development globally as it strives to be a development partner for customers through its cost-saving material solutions.

Mr. Andre Sutter, Key Account Manager-Industry

Grilamid TR and its special properties

Grilamid TR grades are transparent amorphous thermoplastic polymers based on polyamides which, due to their composition, combine the excellent properties of semi-crystalline polyamide 12 grades with those of an amorphous thermoplastic in a unique way. Since Grilamid TR is amorphous, it displays glass-like transparency; and because it is based on polyamides, it also displays high chemical and stress crack resistance, good flexural bending stress and mechanical properties, as well as low density.

Grilamid TR is unique in the fact that it exhibits the three main requirements of processors: transparency; good mechanical properties, such as dynamic strength and fatigue resistance; and chemical and stress crack resistance. In comparison, other amorphous transparent polymers only exhibit one or two of these main requirements. So when it comes to demanding applications requiring all three requirements, Grilamid TR is the only and best choice.

Under the Grilamid TR range, there is Grilamid TR 30 which is a high-stiffness grade with a good scratch resistance. Another grade is Grilamid TR 90 which is flexible and tough, has excellent chemical resistance, and a high fatigue resistance. Grilamid TR 55 has a balanced property profile between flexibility and stiffness as well as exhibiting the best hot water resistance out of the Grilamid TR grades. EMS-GRIVORY's latest addition to the Grilamid TR family is the newly developed Grilamid TR HT 200, a grade that has the highest glass transition temperature out of all Grilamid TR grades, providing good thermal resistance, making it suitable for repeat steam sterilisation use at 134°C for over 400 cycles and suitable for silicone overmoulding applications, along with exhibiting all the other benefits of the Grilamid TR.

Target applications: medical

The presentation of Mr. Sutter also looked at the target applications, specifically for Grilamid TR HT 200. EMS-GRIVORY is predominantly pushing Grilamid TR HT 200 towards applications that require repeated steam sterilisation at 134°C such as suction pump jars, anaesthesia masks, artificial respiration valves, flow metre bowls. Further applications are baby bottles, medical films, and any components which uses or considering to use silicone in combination with a transparent polymer in an overmoulding process.

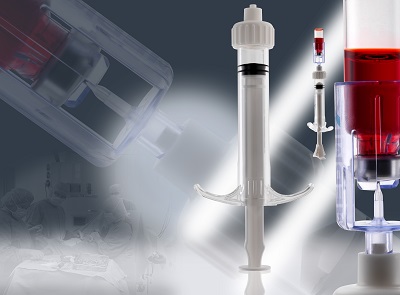

On the reference applications for Grilamid TR for the medical and health care sector, the first one is for a closure system for laparoscopic surgery. In this case, Grilamid TR was chosen due its ability to withstand the required sterilisation process, low density allowing for a lightweight item making it easier to be used by the surgeon or nurse. Another aspect is the material’s good chemical resistance especially against commonly used medical cleaning chemicals and excellent mechanical strength and toughness. Further to this, Grilamid TR allows itself to be easily coloured in transparent or solid colours, and because it is an amorphous polymer, it has low differential shrinkage resulting in low warpage and easier processing.

Another application is for the bone cement delivery system. The reasons Grilamid TR was chosen are similar to the previous example in regards to mechanical strength and toughness, and chemical resistance. In this case, good resistance is needed against the bone cement which is quite aggressive against transparent polymers. Another reason Grilamid TR was selected for this application is its medical approvals in this case, USP class VI approval.

For non-invasive breathing masks, the full benefits of Grilamid TR are visible, such as the being bisphenol-free, lightweight, chemical and stress crack resistant, high heat resistance with good mechanical integrity up to 170 degrees Centigrade, making it especially suitable for silicone overmoulding allowing higher curing temperatures resulting in reduced curing times, as well as good adhesion to silicone with a pull force of over 70 N possible. And last but not the least, the USP Class VI approval. With the spread of COVID-19, this application has risen dramatically in the past few months.

Quite a sizable application for Grilamid TR is for the production of hearing aids. Grilamid TR is preferred by several hearing aids manufacturers due to its high chemical and stress crack resistance. Even chemicals such as skin moisturisers, perfumes, hair sprays can cause issues for amorphous materials but not for Grilamid TR. Approval for skin contact, easy processing and high flowability as well as low warpage are the benefits delivered by Grilamid TR. In addition, the low density enables the production of a very light hearing aids that helps improve the comfort for the wearer.

A further recent development has been the "PA sanitized" grades which are grades preventing bacterial growth on the surface of components made out of polyamides. These grades are shown to eliminate over 99% of surface bacteria, according to the JIS Z 2801: 2010 standard. These are compounded grades based on different polyamides including a range based on Grilamid TR. With all the advantages of Grilamid TR, the medical sector has a better option given its unique properties. And now with EMS-GRIVORY’s Grilamid TR HT 200, the world now has its first transparent polyamide for repeated steam sterilisation applications.

Development support for customers

Mr. Sutter also mentioned the EMS-GRIVORY Development Support it offers to customers. “EMS-GRIVORY can offer design concepts in regards to design proposal and parts cost calculations. After this, we can support the customer in material selection and design evaluation with our more than 30 years of experience in this field. Development support is done on a global level with coordination and support between our technical centres in Asia, Europe, and North America. So no matter where the next product is designed, developed, or manufactured, EMS-GRIVORY can support our customers throughout the whole process,” Mr. Sutter adds.