At K 2019 from October 16 to 23, 2019, SIKORA, manufacturer and worldwide supplier of advanced measuring and control technology, presents a broad portfolio of innovative systems for quality control and process optimization for hose and tube, sheets as well as plastics industries.

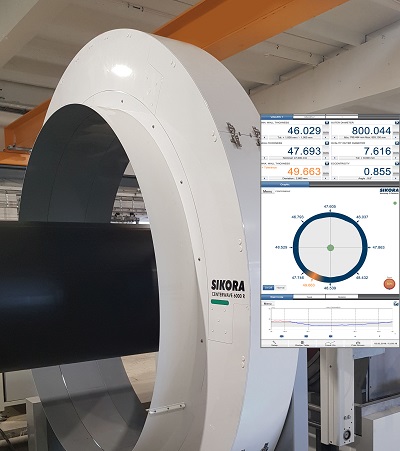

With the world premiere of the CENTERWAVE 6000/1600, SIKORA presents a measuring system of a new dimension. The system was developed especially for quality control of plastic tubes and pipes during extrusion. Due to its design, the system offers a precise measurement of tubes with a diameter from 630 to 1,600 mm. The CENTERWAVE 6000 is based on innovative millimeter wave technology and measures continuously and completely over 360 degrees of the circumference of the pipe the wall thickness, the diameter, the ovality, the inner profile and the sagging.

“The CENTERWAVE 6000 does not only impress because of its dimensions,” says Christian Schalich, Head of Sales Business Unit Hose & Tube at SIKORA, “but foremost due to its benefits resulting from the technology for the extrusion process.” Nominal dimensions are quickly reached, start-up scrap is avoided, the highest quality guaranteed and processes are optimally controlled. Furthermore, the system does not require any coupling media, it measures precisely and independently to external influences, such as temperature or plastics material, and does not require calibration.

Furthermore, the device determines automatically the exact refractive index. It defines the intensity and how fast radiation travels through the material and is therefore decisive for the measuring accuracy. Manual input of modifications of the production conditions is not required. “The operator benefits from a system that, integrated in the line, delivers reliable and reproducible measurement values directly after start-up”, adds Mr. Schalich.