By: Marko Zwinkels, R&D Director Technology Platforms

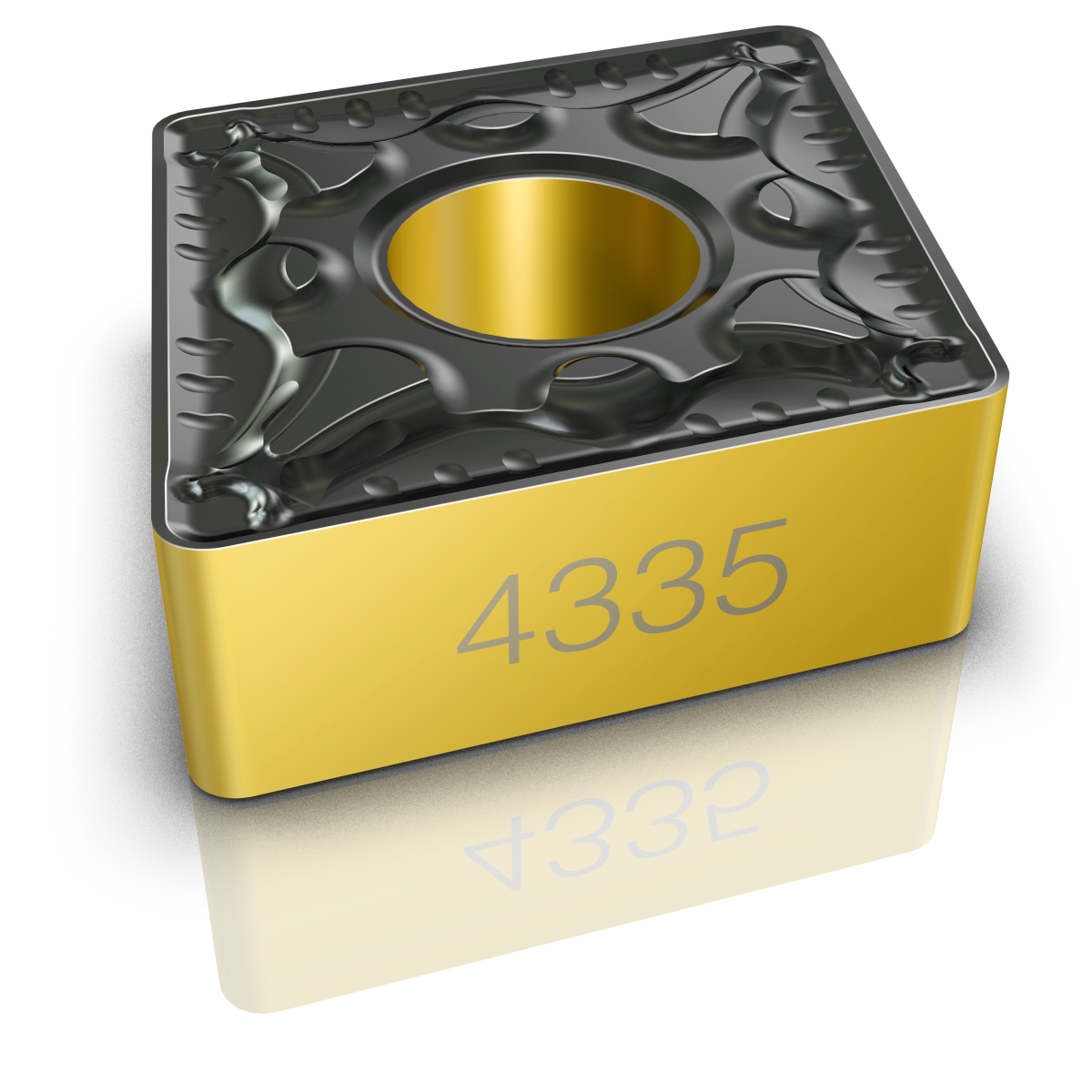

A GC4335 insert manufactured at Gimo

Inserts are used on a large scale and for a wide variety of applications, from milling massive engine blocks and cutting out the moulds used by a sports shoe manufacturer through to machining of dials. The list of specifications for inserts is long: high wear resistance and long tool life, high metal removal rates and maximum reliability, even in challenging conditions such as complex tool paths and deep cavities, great performance in both dry and wet machining and excellent finish surfaces within tight tolerances.

In order to be able to deliver this flawless performance while having to withstand extreme heat and force, inserts are made of some of the hardest materials in the world. Absolute, uncompromised precision is the key to success – that’s why the process of producing them is nothing short of an art form. For Sandvik Coromant, its Gimo facility is one of two manufacturing the powder which serves as a basis for the final product. It is later distributed to other production plants or used for in-house production.

Many steps to success

A typical insert is made of 80 % tungsten carbide and a metal matrix that binds the hard carbide powder together, with cobalt being the most common. The complex process of producing inserts takes more than two days to complete, facing numerous challenges along the way. Other than absolute precision and reliability, cleanliness is a prerequisite. Thorough quality assurance along the entire process is thus not an option, but a necessity.

The first step is getting the mixture of ingredients for every specific powder just right. The tungsten, a finite raw material, is either sourced from Sandvik’s own mine in Austria or from recycled inserts. Cobalt, titanium and all other ingredients come from chosen suppliers who can guarantee consistent quality so as to not compromise the final product. To always be on the safe side, though, each batch is meticulously tested in the lab. The main ingredients are then automatically dispensed into containers at different stops along a weighing line. For some inserts, a very small amount of selected ingredients will be added manually. After passing all the different stops, the full container will weigh in at several hundred kilograms.

The next station is the milling room where the ingredients from the container are mixed with ethanol, water and an organic compound. They will then be milled to the required particle size – typically 0.1 to 5 microns in diameter. This process can take anything between 8 and 55 hours, depending on the recipe for the final product. The result is a grey slurry that is about the consistency of a yogurt drink. The slurry is then pumped into a spray drier where hot nitrogen gas is used to evaporate the ethanol and water mixture.

When the powder is dry, it consists of spherical granules around 100 microns in diameter. A sample is sent to the laboratory for quality check. The now ready-to-press powder is then filled into smaller barrels and processed in the pressing machines, with the organic compound acting as the binder that holds the powder together after pressing. As soon as the mould for the specific insert about to be produced is in place, the cavity of the press tool is filled with powder, and the machine applies up to 50 tons of pressure in the making of a single insert. Even though the process is highly automated, each insert is weighed and at certain intervals controlled visually by the operator to ensure maximum quality and precision. At this stage the inserts are still very fragile, so next in line is the sintering furnace.

Building up resistance

The furnace can accommodate several thousand inserts at a time. They are heated to approximately 1,500 degrees Celsius in a process that takes some 13 hours and fuses the pressed powder into cemented carbide, an extremely hard material. The process causes heavy shrinkage, though: the sintered insert is only about half the size of the pressed piece. After yet another visit to the lab for a quality check, the top and bottom of the insert are ground to the correct thickness. Because the cemented carbide is so hard, a disc with 150 million small industrial diamonds is used to grind it down to the correct thickness. Often, inserts will then additionally be ground to achieve their exact geometry and size.

This is a critical step in the manufacturing process, using 6-axis grinding plates to achieve very tight tolerances, leading to the evolution of a longstanding Gimo joke:. “If you sneeze, the tolerances change”.

Once successfully ground, the inserts are cleaned and ready to be coated. In order to avoid any grease or dust, the inserts must now be handled with gloves. The coating can be done in two different ways, either through chemical vapour deposition (CVD) or physical vapour deposition (PVD). In typical CVD, the substrate is exposed to one or more volatile precursors, which react on the substrate surface to produce the desired deposit. The PVD process takes place in a low-pressure furnace, where the inserts are placed on a carousel and coated in order to become harder, tougher and even more wear-resistant.

After this step, the inserts are ready to be packed and shipped – but not before another thorough quality check. Even though they have been inspected numerous times throughout the whole process, they are manually and visually examined again. In addition, they are compared with the blueprints and batch order and laser-marked with the correct grade.

Keeping the environment in mind

This, however, is just the birth of an insert. As tungsten is a finite resource – as are other raw materials used in the process – rebirth by means of recycling is of utmost importance. As only a very small part of the insert is actually worn away during its working life, most of the material can be used again. There are different ways to recycle valuable natural resources, the choice of which depends on the composition of the insert used: with direct recycling via zinc process, the used carbide is disaggregated into a powder by chemical and/or physical means without changing its actual composition, insuring a minimum of energy consumption and chemical waste; with indirect chemical recycling, all materials are dissolved into their atomic components, resulting in virgin products after purification, extraction and crystallization, followed by thermal powder metallurgical processes.

But also in other production steps, sustainable solutions protecting the environment are in place: The excess heat from the sintering furnace, for example, is recycled and used to heat the premises in the winter or cool them down during summer. In addition, the surplus carbide collected during the grinding process is recycled; so is the oil that is used as cutting fluid.

“Our focus is on uncompromising quality, and to this end, we have established a very thorough process to ensure it,” says Marco Zwinkels, R&D Director Technology Platforms at Sandvik Coromant. “At the same time, we’re aware that we’re handling precious raw materials that should not go to waste, so we’re doing everything we can to make the production environmentally friendly. And that’s why most of the material used for the manufacturing of inserts now comes from recycling processes.”

The production line at Gimo

Nike Hyperdunk 2017