Clariant announced its new dedicated 3D Printing business to meet the demand of the fast-changing Additive Manufacturing market for premium and customized 3D printer filaments.

Additive Manufacturing (AM) is growing at a rapid pace globally, with over 28% average annual growth for each of the last 7 years, and generating a total of $6.063 billion in sales in 2017 (Wohlers Report 20171). Additive Manufacturing has moved from a niche technology to an industry where unique products are produced, for example today over 90% of the plastic shells for in-the-ear hearing aids are manufactured using AM (Wohlers Report 2017). Products manufactured using AM are often complex end-use parts such as air ducts, drones, lights, and parts for manufacturing equipment. These products can be enhanced with tailored high quality and ready-to-print materials that also withstand the wear and tear of prolonged usage.

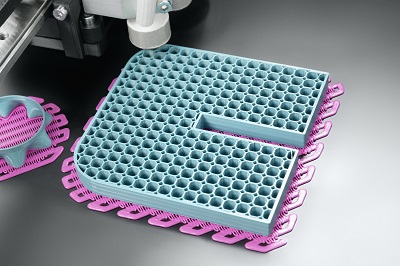

The new Clariant 3D Printing business leverages the company’s numerous years of experience in tailoring polymers for a broad range of end market applications with pigments, additives and masterbatches, to provide high-grade, 3D printer filaments and specially made solutions. Clariant 3D prints and tests all of its materials to ensure printability and the required consistent high quality. Extensive material, application and production expertise allows Clariant to work closely with customers on polymer, additive and colorant selection to address typical end-use conditions such as weathering (sunlight, UV exposure), flame retardancy and electrical properties. In addition to tailored materials, a portfolio of high quality standard material will also be offered. The 3D printing materials are manufactured by Clariant and are available in flexible lot sizes to meet the specific needs of customers.

adidas