A global leader in the extrusion and converting technology, Davis-Standard LLC, has sealed its strong position in the design, development and distribution of extrusion and converting technology. Davis-Standard systems encompass over 10 product lines to support manufacturing applications and customers within every major industry. This includes the agriculture, automotive, construction, healthcare, energy, electronics, food and beverage packaging, and retail industries, among others. With more than 1,350 employees worldwide and a network of independent sales agents and suppliers, Davis-Standard has manufacturing and technical facilities in the United States, Canada, China, Germany, Finland, Switzerland and the United Kingdom.

International Plastics News for Asia (IRNA) had the chance to talk to Sekaran Murugaiah, Vice President, Business Development for Asia, on how the latest additions to Davis-Standard’s product portfolio can benefit the Southeast Asian market.

Mr. Sekaran Murugaiah, Vice President, Business Development for Asia, Davis-Standard LLC

IRNA: What recent products have been introduced by Davis-Standard for the film extrusion sector? Please provide an overview and specifications.

Mr. Murugaiah: Two of the most recent include the dsX flex-pack™ 300S and stretch film technology equipped with a DS S3 winder.

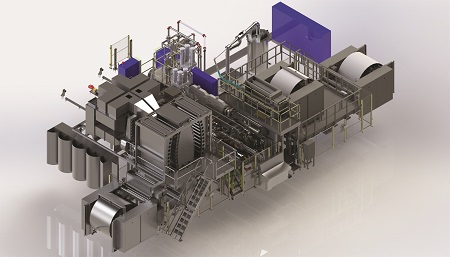

The dsX flex-pack™ 300S is a single station extrusion and laminating line designed specifically for the Asian flexible packaging market. It is a collaboration among Davis-Standard’s teams in the U.S., Germany and China, addressing the pricing, machine footprint, speeds and output, and shorter runs demanded by converters. Davis-Standard is also engineering a tandem configuration of this machine called the dsX flex-pack™ 300T. The dsX flex-pack™ 300S will be available for demonstration in Suzhou later this year.

The stretch film line with DS S3 winder offers a compact machine arrangement, ease of servicing, excellent profile control, consistent roll quality and an intuitive control package. It is engineered for producing thin films from 31-to 51-gauge (7.8µ to 13µ) at high speeds. The side-by-side DS S3 overlapping winder is essential to this capability, enabling maximum slit widths for hand-wrap, machine-wrap and jumbo rolls. This winder also makes it possible for converters to support multiple market segments on one winder.

IRNA: How do these products respond to current market trends?

Mr. Murugaiah: These products address market trends for processing versatility, greater machine capabilities within a smaller footprint, long-term efficiency and value. Specific to the S3 winder, it addresses the handling of thinner films and the down-gauging trend.

dsX flex-pack™ 300S

IRNA: What benefits do these products offer to Southeast Asian film manufacturers?

Mr. Murugaiah: There is double-digit growth for flexible packaging in Southeast Asia with consumers seeking more sophisticated packaging solutions. The dsX flex-pack 300S allows processors to manufacture a range of different packaging structures. Converters are able to achieve results in terms of speeds and output and accommodate shorter runs without sacrificing consistency and quality.

IRNA: What other value-added services related to these products are being offered by Davis-Standard to further improve production efficiency and productivity?

Mr. Murugaiah: In response to the increased demand for “smart” technology, Davis-Standard introduced the DS Activ-Check system for continuous extruder monitoring. Activ-Check enables processors to take advantage of real-time preventative maintenance by providing early notifications of potential extruder failures. Machine operators are alerted to issues before they happen, preventing unnecessary downtime while also collecting valuable data. Key parameters monitored include extruder reducer, lubrication system, motor characteristics, the drive power unit, barrel heating and cooling.

We also continue investment in R&D for extrusion and feedscrew technology to support development of new resins and biodegradable products, as well as energy efficiencies and reliability.