Ms. Marlene Burger, from Country Management South East Asia, introducing the TRUMPF Group and the various laser applications for the production of automotive parts.

The ASEAN Automotive & Motorcycle Parts Manufacturing Summit (AMM), organised by Ringier Trade Media, held its first conference in Vietnam and hosted over 200 participants and 26 speakers from 13 different countries. As a partner of the conference, TRUMPF participated with a presentation speech and an exhibition booth, providing expertise and innovative solutions for manufacturers and suppliers.

In Vietnam, the automotive market has developed from being a low volume market with mainly one automobile brand to a continuously growing and stable market. Although the market size is still relatively small compared to countries such as Thailand or Indonesia, the market in Vietnam offers a lot of potential due to the young and abundant workforce and steady growth in GDP.

The growth in the automotive industry has also led to an increase in demand for tools to manufacture automotive parts. As an expert in the field of automotive manufacturing, The company provides a wide portfolio of tailored solutions for automotive industry that open up entirely new production possibilities.

It acts as a reliable partner to its automotive customers, from the initial idea in advance development, to process-compliant component design, process development, and the setup of the production system. Apart from large-series production with machine tools and laser technology, the power tools from TRUMPF also play a key role in repair, tuning, and customising work.

TRUMPF lasers can execute a wide variety of processes in automotive manufacturing, such as the production of e-drives, the laser welding and laser cutting of a wide variety of components in battery systems in electrical vehicles or the processing of materials used in the interior of the car. The company’s lasers also open up entirely new possibilities when it comes to processing lightweight materials. The lasers can be used to join hybrid components comprised of several materials and the flange width can also be reduced effectively. The result is the production of smaller, lighter, and more cost-effective components.

CARS- Made by Laser

Automotive manufacturing is a key future field for TRUMPF. The rate of innovation in this area is high. Alongside the variety of materials used in the vehicle body and power train, the increasing trend toward electric vehicles represents a key field with many new applications. TRUMPF acts as a reliable partner to its automotive customers, from the initial idea in advance development, to process-compliant component design, process development, and the setup of the production system. With our extensive industry expertise, we help automotive manufacturers and suppliers to get to grips with new technologies and drive their own products forward. Apart from large-series production with machine tools and laser technology, the power tools from TRUMPF also play a key role in repair, tuning, and customising work.

Electro-mobility

Key components in electric vehicles are manufactured with laser processes. TRUMPF lasers enable its e-mobility customers to use productive, high-quality manufacturing methods. The highly intricate processing enables compact assemblies such as e-drives to be easily produced with only minor negative thermal effects. Innovative optics and new wavelengths and processes also enable low-spatter or completely spatter-free welding of copper materials. With our high-end laser systems offering maximum beam quality, new join and welding geometries and welds can be implemented on conductive metals (aluminium, copper, and nickel). The lasers can also easily handle fine processing on sensors or welding jobs on batteries.

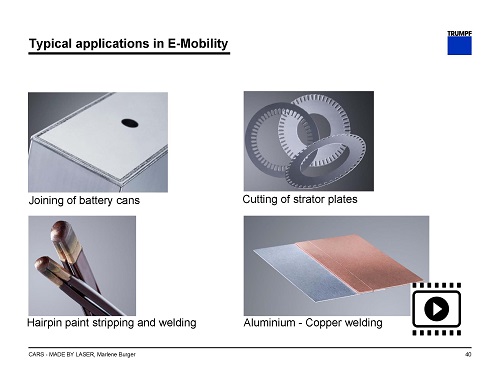

Typical applications in E-mobility

Joining of battery cans: Lasers are ideal for sensitive battery cells and their casings, the cans, as they operate with no contact and with almost no energy input. The material is not subject to mechanical load. The locally limited, how heat input caters for high-precision, distortion-free seams.

Hairpin paint stripping and welding: To prepare hairpin welding, customers use the company’s short-pulse lasers that remove the insulating paint coating without damaging the copper below. The process delivers more precise results than mechanical coating removal process. Intelligent sensor systems ensure precise seams when welding the hairpin thus ensuring optimum quality. Thanks to the high reproducibility of the laser welding processes, customers achieve consistently high-strength connections with good conductivity and they do so in large quantities as well.

Cutting of strator plates: Delicate contours can be cut very quickly and precisely. Customers can profit from high reproducibility and the lack of distortion, even when joining stator packages in prototype construction.

Aluminium – copper welding: The company laser weld housings of differential gears with crown wheels, reliably, flexibly and without contact. They enable many multi material connections for light-weight construction. The combination of cast iron and case-hardened steel is the most common. The high-precision laser welding technologies also contribution to a significant reduction in undesired running noises of the differential gear during operation.

The laser expert opens the automotive industry a multitude of manufacturing possibilities in all areas of electrical mobility. From high-end laser systems with the highest beam quality to intelligent quality assurance systems and the establishing of complete production plants, TRUMPF is a partner to its customers in the area of eMobility. With its deep knowledge of a variety of industries and applications and worldwide laboratories, they support various industry sectors in understanding new technologies. Working together with them on many projects, the company develops innovative solutions for the challenges of eMobility that arise. To do so we are involved in the entire development process from the initial idea to the start of production.

Team members from Hanoi, Ho Chi Minh City as well as from the country management joining for the AMM summit.

Adidas Falcon