If you’ve ever struggled with inserts coming loose during a slotting operation, keep reading. How about inconsistent slot widths, fumbling with awkward screws and inserts on a slotting cutter, or having to use a piece of shim stock to pry wedged chips from deep inside a slotted workpiece? These are just a few of the problems machinists face when trying to cut narrow slots and grooves, but thanks to the newly introduced Kennametal Narrow Slotting (KNS) cutter, the days of “slotting dread” are over.

Many uses, one solution

Slotting is a common machining practice. Scott Etling, Kennametal’s Director of Global Product Management for indexable milling, lists many applications where the KNS excels. Automakers can use the new cutter to separate cast exhaust manifolds and steering components. Equipment manufacturers can cost-effectively mill the clamping slots on shaft supports and stock collars. Power generation and electronics companies now have a more productive way to machine keyways, add heatsink grooves, yokes, and O-ring grooves. Simply put, if there’s narrow slotting, grooving, or parting to be done, KNS is the new go-to solution.

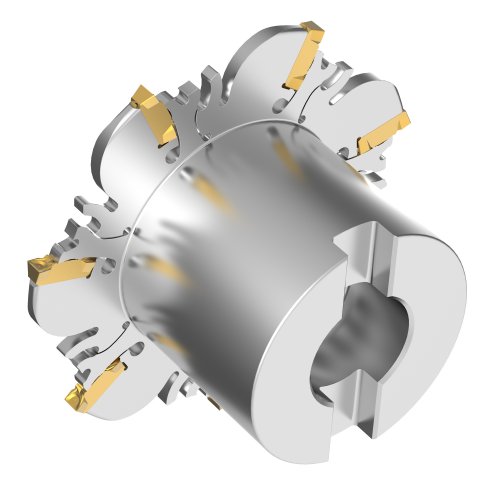

Kennametal’s KNS slotting platform provides a cost-effective but highly productive solution across a wide range of applications

“This tool is a game changer in a number of situations,” Etling says. “Customers can mount a series of KNS cutters on an arbor called “Gang Milling” to either machine multiple grooves at once or conduct multiple cutoff operations. This tool can also be used to remove five-axis machined or 3D-printed parts from their base material. And since raw material prices continue to increase, our customers wish to machine away as little material as possible. Here it’s beneficial to use the narrowest slotting cutter possible to reduce waste. KNS does that.”

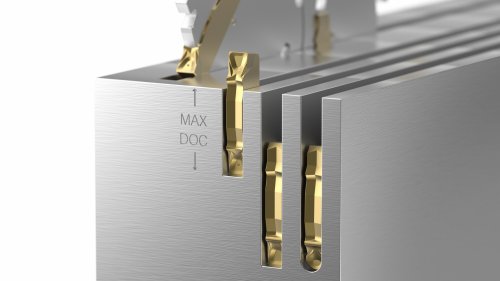

Besides inserts for deep slots with flat bottom and radiused bottom. For shallows slots, KNS offers a very cost effective solution with double ended inserts (2 cutting edges).

The Right Stuff

The KNS has a Double-V design for secure insert retention. A combination of radial and axial positioning not only improves tool life but part accuracy as well. The insert range accommodates slot widths from 1.6mm to 6.4mm (0.063-inch to 0.250-inch). Inserts are available in single- (dash to be used here?) or double-ended cutting edges with either a flat or full radiused cutting edge. The cutter diameters range from 63mm to 250mm (2.5-inch to 10-inch), and depending on the body size, arbor or shell mounting (or both) is possible.

The KNS boasts a simple but secure Double-V to accurately locate inserts. There’s no chance of movement as there is with other kinds of slotting and grooving cutters. Tool life improves, as do part quality.

“We're really excited about this new design,” he says. “It’s stronger and more accurate than competing solutions and reduces tooling costs as well. Customers can use both ends of a double-ended KNS insert on shallow slotting applications, then move to a single-ended insert when they need the additional depth. It definitely offers a lot of value.”

A real winner

These features already give Kennametal a substantial lead over the competition in the narrow slotting market, but the benefits don’t stop there. There’s also the carbide. Tim Marshall, senior global product manager for indexable milling notes that Kennametal has made significant improvements in grade technology recently, and that the KNS leverages these developments.

“With the KNS program we offer three insert grades,” he says. “KCU25 and KCPM40 are multiphase PVD grades that provide excellent edge stability and wear characteristics in steels, stainless steels, and high temperature alloys, even at elevated feeds and speeds. While KCPK30 is a CVD-coated grade suitable for rough milling and general machining of steels and cast iron.”

Good carbide is important, but so too is the insert geometry. Thanks to a positive rake geometry and special edge preparation, the KNS inserts are free cutting without sacrificing the edge toughness needed in most slotting applications. What’s more, the SGP geometry promotes excellent chip flow, curling even the stringiest materials into tight, easily-evacuated Cs and 9s. This means you can put the shim stock and home-made chip hooks back in your toolbox.

Easy-X assembly

The KNS is also easy to use. The innovative, symmetrical Easy-X wrench design means no more digging in the chip pan for lost screws and inserts, no more wedges or clamps to misplace—just pop the wrench into the cutter body, give it a twist, and the insert is easily replaced, even in tight quarters. Each cutter body and wrench are also clearly marked, so there’s no chance of damaging the cutter body by using the wrong tool.

Last but not least the integral hub design. This eliminates the need for drive rings and washers, and greatly contributes to the system’s repeatability and accuracy. And because the hub has dual keyways, the cutters can be staggered in gang-milling scenarios, reducing cutting forces and generating a smooth cutting action.

“We feel quite confident in saying this is the best solution available for narrow slot machining,” Etling says

The KNS system’s dual keyways provide staggered entry in gang milling situations, reducing cutting forces. And the integral hub is both more accurate and rigid than competing systems.

nike