The teams have been gradually incorporated following the indications of the local authorities and have now reached an operational capacity of 97%.

"Our priority has always been the safety and wellbeing of the people and we have taken all the measures within our power to guarantee this," stresses the manager of Fagor Arrasate's plants in China, Alberto Sarasqueta.

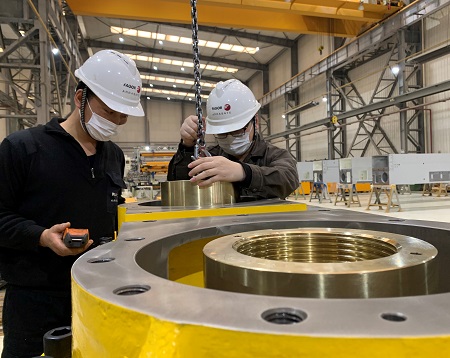

Specializing in the design and manufacture of machine-tools by deformation and forming, the European company has 2 plants in Kunshan, located 50 km from Shanghai. The factories remained closed from January 24 to February 10, the date until which the government extended the Chinese New Year holiday. From that day on, the companies could apply for permission to resume activity and for their staff to return to work. Once the procedure was completed (some time between 12 and 19 February) the workers returned to their jobs in 3 groups. In order to obtain these permits, the plants have had to meet the requirements imposed by the authorities regarding the adoption of preventive measures for contagion and cleaning of the facilities, as well as having an inventory of sanitary material. In order to certify compliance with these requirements, it has been necessary to pass the corresponding audits.

Fagor Arrasate's Chinese subsidiary has been monitoring the situation of local suppliers, which have needed a few more days to recover their activity, given that the government has prioritized the reopening of foreign companies. However, today both the supply chain and the internal operations of the company are already underway.

The importance of internationalization

The current pandemic has highlighted how crucial internationalization is and how setting up in the Asian giant with productive capacity is a wise decision. In the case of the European company, the Chinese subsidiary is playing a very important role in supporting the group's industrial and service activities. This multi-location feature makes it possible for a machined part that cannot be supplied from the European facilities at present to be sent from the Chinese plants to the Mexican plant, for example. In this way, Fagor Arrasate can continue to offer its technical assistance services to its customers.

The role of the Chinese subsidiary is reinforced by the fact that it is a multidisciplinary plant that covers the three business areas of the company: the automotive, steel and household appliance sectors. It also has the ability to offer technical support and assistance services in other parts of the world.

This local production capacity places Fagor Arrasate in a strong position when compared to its competitors, as it is the only one with a presence in China in the sector of sheet-metal cutting and processing. "If a project were to arise today, unlike the vast majority of our competitors, we would be in a privileged position to offer the customer the assurance of a solution through our subsidiary. We would be one of the few foreign manufacturers that could offer service guarantees," points out Sarasqueta.

In his opinion, the economic development of sectors such as the automotive and steel industries in China will depend to a large extent on the measures to stimulate consumption and investment implemented by the government. In any case, he emphasizes that there is an important margin of maneuver thanks to the abundance of liquidity provided by the very positive trade balance of the last decade.

The first Fagor Arrasate plant in Kunshan was opened in 2008 and the second in 2012 under the premise of "European design, local manufacture." Its objective is to closely and directly meet the needs of the Chinese market with the same technology and quality standards that characterize the production of European plants. They are focused on supplying the local market, manufacturing sub-assemblies for the rest of the company's plants and acting as a purchasing platform for the group. Within the country, there are offices in Beijing and Shanghai as well.

New Balance Popular Collection