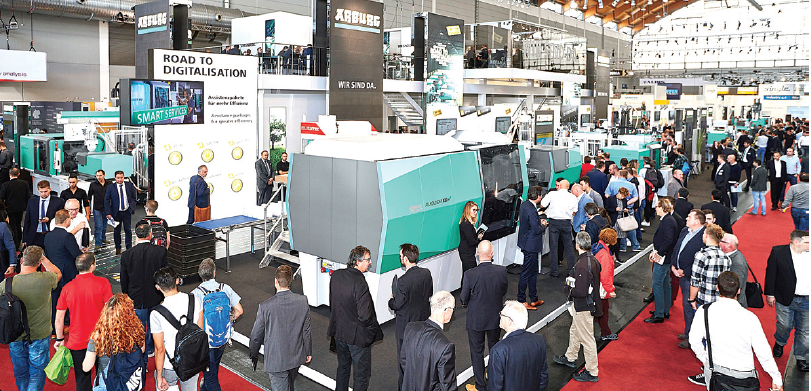

Everyone who’s anyone in the field of plastics processing came together at the once again fully booked out Fakuma international trade fair for plastics processing on Lake Constance where Germany, Austria and Switzerland meet for the 26th the time from October 16-20, 2018. Whether from Europe, North America or Asia, those engaged in plastics manufacturing agree that Fakuma continues to be an important exhibition where new plastics processing technologies are introduced to the world. The international exhibitors, as well as private trade fair promoters P. E. Schall GmbH & Co KG, were pleased once more this year with the great demand in the field of plastics technology as reflected in the 1,933 market and technology leaders from 40 countries that presented their products to 47,650 visitors from all over the world!

The proactive technology transformation appears to be succeeding in the field of plastics processing: New materials, more efficient manufacturing processes, 3D and 4D printing alternatives, digitalised and automated production solutions, reduced energy consumption for machines and systems – these are just a few of the regulating screws that need to be tweaked by today’s plastics processors. The issue of sustainability, including aspects such a plastics recycling, material savings and biomaterials, was the subject of more discussion than ever before at this year’s Fakuma, because the demands of plastics users such as the automotive industry and the consumer goods and packaging manufacturers are becoming more and more complex. Fakuma 2018 very impressively verified the fact that the plastics industry is up to the challenge, and that it has the most up-to-date tools at its disposal in every regard, in order to work economically with efficient use of materials and resources.

The production of affordable, and at the same time rugged lightweight design structures was presented at the event to just as great an extent as a broad-based portfolio of new materials. New machines, adapted tooling, integrated quality assurance, controllable hydraulic and to an ever greater extent electric drives, and last but not least networkable and thus communicative controllers complete with software – the plastics industry is becoming more and more digital, which is not least of all made apparent by great demand for Industry 4.0-capable equipment and systems.

Arburg promotes “Road to Digitalisation” at Fakuma 2018

The compact Friedrichshafen Exhibition Centre on Lake Constance was once again fully booked out. Manufacturers and distributors from outside of Germany now account for more than 42% of the total number. Internationalism has been growing for years. Not least of all the publicity surrounding 3D/4D printing technology and additive manufacturing is causing more and more new and established suppliers from all over the world to appear on the scene, who supplement the portfolio with highly interesting solutions at Fakuma as a globally leading trade fair for plastics processing.

With 47,650 expert visitors from 126 countries, Fakuma plays an important role. The exhibitors all agree: The visitors demonstrate high levels of expertise and the technical discussions are of “high-quality”. Consequently, the exhibiting companies were more than satisfied and their comments were entirely positive.Clear-cut positioning as a trade fair for plastics processing – and not as a multi-technology event for plastics issues – makes an essential contribution to Fakuma’s excellent reputation as a technical industry meet. It’s strictly practice-oriented alignment to the process sequence for plastics processing is a further important success factor for the industry event.

Economic growth of the plastics processing industry is only being impeded by the lack of qualified personnel. As a result, expert meeting places like Fakuma are being used to an ever greater extent for recruiting purposes. The objectively oriented supplementary program is an ideal opportunity for technical further training, and at the same time for meeting interesting people. This year’s series of events with 69 technical presentations was the ideal setting for expert visitors and exhibiting companies to gather comprehensive information about a great variety of issues.

Glimpse of the future

At the Fakuma 2018, Arburg provided insights into the digital present and future of injection moulding: on the “Road to digitalisation”, digital products and services were presented and, in numerous expert talks, introduced in detail to the trade visitors. “With the ‘Road to digitalisation’ and numerous practical examples from day-to-day injection moulding practice, we delighted our customers and demonstrated just how well positioned Arburg is with regard to the digital transformation. All those who are interested in this area found exactly the right partner in Arburg, regardless of whether they are just setting out or have already travelled part of the way,” summarises Michael Hehl, Managing Partner and Spokesman for the Management Team. “The Allrounder 820 H in the new clamp design and ‘Packaging’ version, as well as the new ATCM SCADA system for Arburg turnkey systems also celebrated their premieres. Moreover, with the injection moulding of LSR micro components, the topic of Industry 4.0, the production of technical moulded parts and additive manufacturing, we presented some exciting applications on our ambitious exhibition stand.”

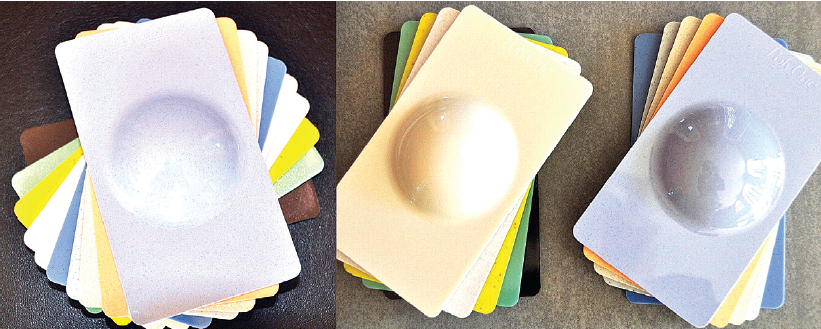

Polyone “Shades of Nature” shows off on-trend colours for polymers.

The focus at Fakuma was on digital transformation, an area in which Arburg is a leading influence on the industry. The unanimously positive feedback from the visitors demonstrated that Arburg has struck the nerve of the times with its “Road to Digitalisation”. An insight into the future was offered by the Gestica control system featuring filling simulation, augmented reality (AR) for “smart” service, as well as new cloud-based services.

The hybrid Allrounder 820 H in the clamp design and with the Gestica control system in the special “Packaging” version celebrated its premiere. In a cycle time of 3.8 seconds, it produced four thin-walled IML containers. Equipped with four assistance packages, this high-performance machine for the packaging industry was “ready for digitalisation”. With immediate effect, these packages are included as standard with all Allrounder machines featuring the clamp design and the Gestica control system. The new Arburg Turnkey Control Module (ATCM) also garnered a great deal of interest. This SCADA system for complex turnkey systems from Arburg visualises the complete process, captures the corresponding data and transmits the partspecific data sets to an evaluation system for archiving or bigdata analysis, for example.

In the materials section, PolyOne revealed its newest collection of on-trend colours for polymers, called Shades of Nature. As part of the OnColor™ Polymer Colourants masterbatch portfolio, this group of ten masterbatch colourants enables plastic to mimic naturally occurring materials such as stone, marble, and granite. It was developed to address a trend towards creating products that appear more natural and less manufactured.

Designers today increasingly value individuality over uniformity in markets such as cosmetics, electronics, appliances, and building materials. This trend began with the ‘green’ building movement, which revels in imperfect and textured natural materials such as bamboo, stone, marble, and minerals.

Formulated using a proprietary process, colours in the Shades of Nature Collection gives brand owners a wide range of possibilities in creating individual, artisanal looks in plastic. Each shade is created from colour pigments and particles, ranging from almond shells and reflective flake to synthetic fibres and pearlescents. In combination with surface texture and part geometry, these masterbatches give plastic parts the appearance of naturally-occurring materials so that, for example, designers could create a toaster that appears to be carved out of granite.