Fomtec’s first IPF participation was a refreshing experience. The company manufactures Vertical Clamping, Vertical Injection Molding Machine, Tie-bar Less Vertical Clamping and Horizontal Injection Molding Machine, and Direct Hydraulic Clamping Horizontal Injection Molding Machine.

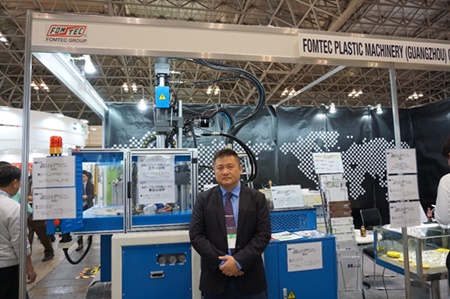

Fomtec Business Manager Percy Yu introduced at the booth the Liquid Silicone Rubber Injection Molding Machine and Vertical Injection Molding Machine with servo systems. Mr. Yu explained the potential of using silicone rubber as materials, “Silicone rubber carries great stability and property resistance to extreme environments from +200°C to - 60°C. It has a 94% high degree of light transmittance that is better than glass and general plastic, thus useful for lamppost, automobile headlights, and other industrial and daily applications in medical, electronics, etc”.

Being a first-time exhibitor at IPF, Mr. Yu observed that the visitors were extremely professional and expertise-oriented despite the show scale not being as huge as Chinaplas. Fomtec received positive feedback, and successfully sold the machine exhibited at IPF. In the future, Fomtec will focus its core strength in innovation for injection molding and in material technology. In addition, energy efficiency has been the company’s focus as hydraulic servo systems are embedded in its machineries, which perfectly reflected the theme in IPF 2017 of composite materials and greener plastics industry.

For its medium-term operational strategy, Fomtec is particularly enthusiastic in the forming technology of carbon fiber reinforced polymer, and the diversification of this technology’s application. Mr. Yu shared that the company will develop a horizontal product line so that it would not be affected by volatile global economy as the products for different sectors will compensate one another.

Fomtec Plastic Machinery (Guangzhou)

Tel: +86-20-3685-0111

E-mail: os@fomtec-group.com

Website: http://www.fomtec.cn/

Nike Air Max 1 For Sale