BIG KAISER, a global provider of premium high-precision tooling systems and solutions for the metalworking industries, recently demonstrated its prototype EWA system – the future of fine boring – at the International Aerospace Forum 2018 organized by Makino, a world leader in advanced CNC machining centers.

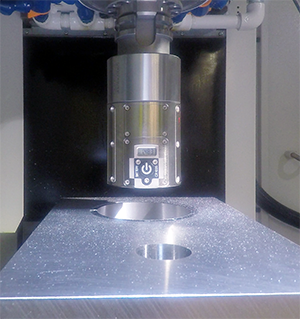

At the event, held in Germany, BIG KAISER presented a prototype of the EWA, an automatic fine boring tool. The EWA provides fully-automated machine tool operation without the need for a human operator. This makes fine boring more accurate, faster and less expensive.

With the EWA, there is no need to stop the machine tool to take measurements and manually adjust the boring tool, which saves considerable time. By also eliminating the human factor, the likelihood of having to scrap expensive workpieces due to human error is essentially mitigated. This reduces costs, improves accuracy, whilst enabling handling of multiple bore sizes and repeated bores, and avoids the need for time-consuming manual wear-out compensation.

Jose Fenollosa, Head of Electronic Development at BIG KAISER, said, "In industries such as aerospace, the scrapping of a single workpiece can cost easily upwards of $50,000; the EWA mitigates this risk to a minimum. Fine boring is faster, accuracy is higher and the human factor is much less of an issue. The EWA brings a new level of automatic control to Industry 4.0 and the smart factory concept."

The EWA can be used in three primary configurations. Firstly, it can be operated as a standalone tool, controlled via a tablet with a wireless connection. Secondly, for legacy machine tools, a PC interface between the machine tool and the EWA can be used to provide a fully-automated, closed-loop control cycle, where commands are sent from the machine tool to the EWA, automatically adjusting or stopping the machining process when required. Thirdly, for newly-developed machine tools, EWA control software can run directly on the machine tool itself to provide an equivalent level of automatic control, requiring no external control device.

BIG KAISER is working with Makino and other forward-looking organizations to make this level of integrated automation the new reality of Industry 4.0.

The EWA system is based on BIG KAISER's EWE digital fine boring heads and the EWN precision boring heads and is being developed entirely in-house.

Air Jordan XI 11 Wool