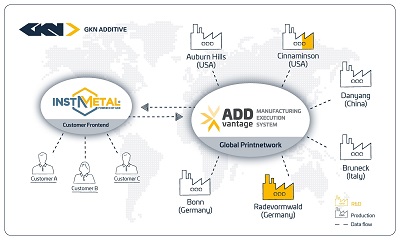

The global printnetwork enables scaleability and faster deliver to GKN Additive's customers (PRNewsfoto/GKN Additive)

At the state-of-the-art facility in Danyang, customers and partners can learn about all aspects of metal 3D printing and work with GKN Additive's engineers to design and print components with hands-on prototyping workshops.

The new location now extends the reach of GKN Additive's global print network to Asia. Today, six R&D and manufacturing locations across Europe, North America and Asia form a digital print network, embedded in Industry 4.0, to ensure global scalability and faster delivery to GKN Additive's customers.

"China is the world's largest automotive market and automotive manufacturing country for conventional and new energy vehicles. Automotive development activities have shifted from traditional regions to China, and this leads to an increased demand on new technologies like additive manufacturing," said Guido Degen, President Additive Manufacturing at GKN Powder Metallurgy.

"We believe that metal additive manufacturing is one of the future processes that will have great effect on the automotive industry and electric vehicle production. From saving time to market through rapid prototyping to redesigning and rethinking parts and assemblies for additive, to reduced inventories by on-demand replacements - metal AM adds value during the whole component life cycle."

Already established as one of the top 5 suppliers of the Chinese premium automotive market

GKN Powder Metallurgy, comprised of GKN Hoeganaes, GKN Sinter Metals and GKN Additive, employs a team of more than 500 people across two locations in Danyang and Yizheng in the coastal Jiangsu province, north of Shanghai. Since entering the Chinese market in 2006, GKN Powder Metallurgy has gained market share each year and is now one of the top five suppliers of the Chinese automotive premium market.

GKN Powder Metallurgy China manufactures highly engineered metal powders and sintered products primarily for automotive engine, transmission and body & chassis applications. In 2018 both facilities supplied millions of VVT rotors, VVT stators and synchronizer hubs to leading automotive customers in China, like Schaeffler, Denso, VW, Getrag and JATCO.

Adidas Fotballsko