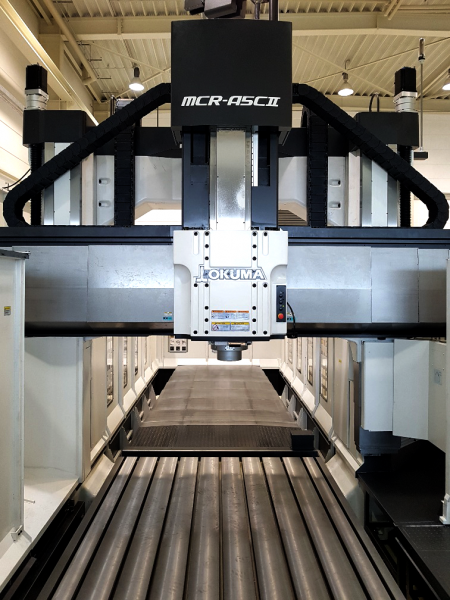

With over 50 years of experience, 8,000 machines installed around the globe and an unparalleled production capacity of 40 units per month, Okuma is the world’s leading manufacturer of double column machining centres. By adding the MCR-A5CII to the showroom, the CNC provider is now making its extensive large parts machining expertise available to customers at its Okuma Technical Centre (OTC) East. Dubbed as a ‘manufacturer’s playground’, these facilities allow visitors from a wide range of industries to test the latest machines and technologies and to discuss their machining needs with the Okuma experts on site.

The compact MCR-A5CII features an AAC (Automatic Attachment Changer) which changes attachments within 30 seconds. It includes a stocker for two attachments as standard to make true 5-sided machining possible in a single setup. In this way, the double column machine reduces setup and downtime and minimises the potential for costly errors. With a 2,000 x 4,800 mm table, spindle speeds of 6000 min-1 and a maximum output of 26/22 kW (30min/cont), the MCR-A5CII achieves powerful large parts machining. An 80-tool ATC for horizontal and vertical attachments further increases productivity. With a footprint of only 6,830 x 12,550 mm, the machine takes up relatively little floor space for a double column centre.

The solid cast iron double column construction ensures greater rigidity and closer tolerances. Outstanding accuracy and dimensional stability are the result. A Renishaw touch probe enables on-machine gauging of complex shapes in mid-process.

Okuma’s Intelligent Technology SERVONAVI significantly increases productivity by optimising cutting and feed rates. The user-friendly OSP-P300M CNC ensures easy operation. For maximum workpiece accuracy and higher productivity, the MCR-A5CII comes equipped with Okuma’s Thermo-Friendly Concept, which stabilises thermal deformation, shortens warm-up times and reduces the need for dimensional correction during operation.

The MCR-A5CII can be configured with different spindles, a wide range of attachment heads and ATCs. Table size varies from 1,500 to 3,000 mm in width and 3,000 to 12,000 mm in length. Many additional setups are available.

Nike KD