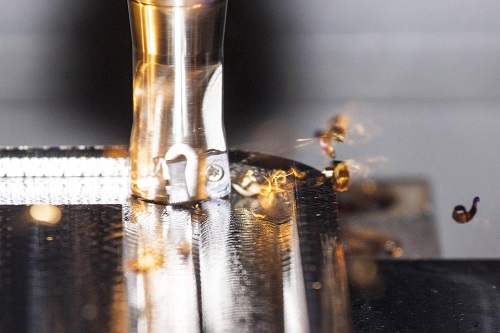

The versatile Pramet SBN10 cutters are suitable for copy milling, ramping, helical interpolation, slotting and plunging. Its unique pocket design can also carry inserts for shoulder and face milling, offering a complete package for, in particular, mold and die applications, from roughing to finishing.

A range of diameters are available from 16 - 42 mm and multiple types, including end mills, modular and shell mills.

To support this addition, Dormer Pramet has introduced an assortment of BNGX10 inserts for high feed roughing. The patented double sided insert with four cutting edges provides an economical and versatile option.

Its design makes it suitable for high feed roughing even with long overhang, while being compatible with three geometries covering most machined materials. Geometry M is for steels and cast irons, MM for low carbon steels, stainless steels and super alloys, while HM is suitable for hardened steel.

Also, a new range of Pramet ANHX10 inserts is now available for finishing operations in shoulder and face milling. The single-sided insert has two cutting edges and a positive geometry for long overhang, helping to decrease vibrations and reduce noise.

Both inserts offer a smoother cut, while a special through coolant design directs lubrication nearer to the cutting edge. This allows for high feed rates with axial depth of cut up to 1mm. A higher ramping angle improves chip control.

To find out more about all new products launched in November 2017 contact your local Dormer Pramet sales office. To download a pdf version of the Pramet 2017.2 new product brochure visit www.dormerpramet.com.

Watch the new Pramet range in action on Dormer Pramet’s YouTube channel www.youtube.com/dormerpramet.

Adidas