The use of stainless steel for engineering applications has always led to something of an engineering paradox. While design engineers are extremely happy with the strength and corrosion-resistance properties offered by this common material, production engineers are perhaps less enamoured with its work-hardening characteristics and general lack of machinability. However, with sectors such as pump and valve, oil and gas, automotive and aerospace continuing to specify stainless-steel components, the challenge for cutting-tool manufacturers is to deliver solutions that can provide ever-greater tool life and/or productivity to help machine shops succeed in an intensively competitive global marketplace. At Sandvik Coromant, there are high hopes for one such new solution.

The challenge

There are many different family groups within the ISO S stainless-steel material classification. However, two of the most common are austenitic stainless steels and duplex stainless steels.

Austenitic stainless steels include familiar grades such as 304 and 316. Although relatively soft in the annealed condition, and with very good ductility, these grades undergo extensive work hardening during any form of machining. Work hardening produces hard surfaces and hard chips, which in turn lead to notch wear and compromised surface finish on the workpiece.

The high ductility of austenitic stainless steels also works against successful turning. These materials produce long, tough, continuous chips that are difficult to break, while an accumulation of metal at the cutting edge can also occur (known as built-up edge – BUE). The thermal conductivity of austenitic stainless steels is low compared with other steel types, so heat can easily build up at the cutting-tool face. Here, distortion or poor tolerance control during turning can be affected by the high thermal expansion rates of these steels.

With regard to duplex stainless steels, which include grade 2205 for example, the structure of these materials is a mixture of ferrite and austenite. They have higher tensile strengths than austenitic stainless steels, and while work hardening is not as significant as for austenitic grades, the higher strength means higher machining forces (power) and lower speeds are needed. In fact, the relative machinability of duplex stainless steels is generally considered to be poor due the high tensile strength and yield point.

Turning duplex stainless steel produces strong chips, which can cause chip hammering and create high cutting forces. In addition, a lot of heat is generated, which leads to plastic deformation and crater wear.

The solution

There are many established tips and tricks when it comes to turning stainless steels. For instance, with austenitic stainless steels, the use of sharp edges that can cut under the work-hardened layer works well, particularly when keeping the cutting depth constant. For duplex stainless steels, small entering angles are preferable to avoid notch wear and burr formation, while stability in tool clamping and workpiece fixturing is essential.

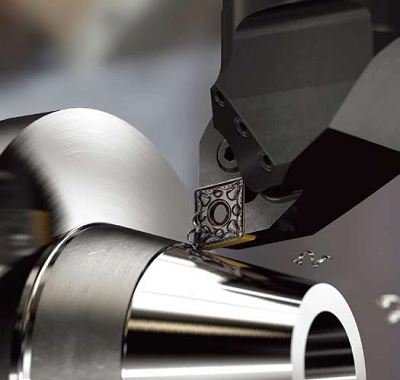

Despite this knowledge, the real gains in turning stainless are linked directly to correct insert selection. However, until now, finding a suitably hard grade for the high-speed, stable-condition turning of stainless steel in rough to medium applications has proved somewhat challenging. Machine shops turning austenitic and/or duplex stainless steel parts need an insert that is able to combat plastic deformation and wear to provide more parts per edge and therefore reduce cost per component.

Listening to customer feedback on this subject, Sandvik Coromant has developed insert grade GC2220. The new grade features an optimised substrate with reduced cobalt content to provide heat resistance, along with a columnar MT-TiCN inner coating that is hard and resistant against abrasive wear. Perhaps most importantly of all, GC2220 features proprietary Inveio™ coating technology for long tool life. The tightly-packed uni-directional crystals produced by Inveio create a strong barrier towards the cutting zone for maximum thermal protection.

As a result of 25-30% higher resistance to plastic deformation in comparison to previous generation grades, the extended tool life afforded by using GC2220 for turning austenitic and duplex stainless steel components means less tooling expenditure and reduced inventory, as well as lower cost per part. Fewer insert changes also improve productivity, ensuring faster return on investment.

The results

In terms of cutting conditions, the best results are seen in stable machining environments with continuous to light interruptions for average to high cutting speeds, as exemplified in a number of case studies at pump and valve industry customers.

For instance, when performing external axial turning and facing operations on a valve made from austenitic stainless steel (200 HB), the competitor grade showed extensive plastic deformation along the cutting edge after 230 components (12 seconds in-cut time per part). Cutting data included 107 m/min (350 ft/min) cutting speed, 0.3 mm/rev (0.012 inch/rev) feed rate and 1.3 mm (0.05 inch) depth of cut.

While the competitor grade had to be replaced at this point, the Sandvik Coromant GC2220 grade showed hardly any damage to the cutting edge and was able to continue, eventually completing 522 parts before replacement was required, a 127% increase in tool life.

In a similar test, this time performing external axial turning on an austenitic stainless steel (200 HB) flange for the pump and valve sector, the competitor insert lasted just seven parts before replacement was required (47 seconds in-cut time per component). The cutting speed was 160 m/min (525 ft/min), feed rate was 0.2 mm/rev (0.008 inch/rev) and depth of cut was 2 mm (0.08 inch).

Principal among the reasons for insert replacement was the extensive amount of plastic deformation witnessed along the cutting edge. Conversely, GC2220 showed far less plastic deformation and was able to continue for a further 12 components, equating to 71% more tool life.

Also worthy of note is that GC2220 can be used in both wet and dry machining operations, and be applied successfully to other materials that include martensitic stainless steels and low carbon steels.

Mujer