THE conveyor belts from Forbo feature two-sided coating that reduces the chance of meat or poultry being contaminated by oil, grease, moisture or other contaminants. The Prosan Conveyor (FF) belt has virtually lint-free edges. A special type of fabric and weave, as well as an enhanced filament length, protect the edge of the belt.

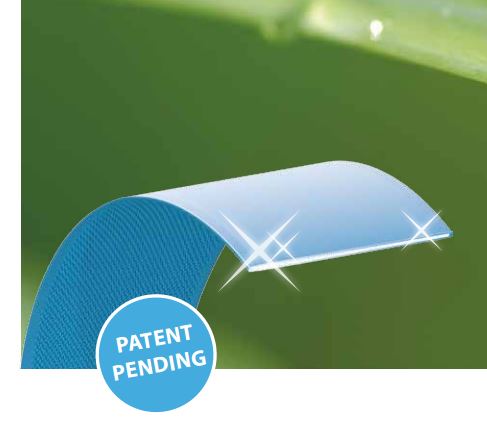

The Smartseal™ option provides extra sealing so that the belt is completely enclosed and fully protected. The patented Smartseal™ method is suitable for sealing a wide range of belt thicknesses and thanks to superior flexibility the belts can also operate over knife edges.

Low friction coefficient ensures cost-efficient operation

Another special characteristic of Prosan™ belts is the innovative pattern on the underside called broken twill (BT). The advantage of this underside pattern is its low friction coefficient towards the slider bed and the fact that it’s easy to clean. A patent is pending on this special pattern.

Small reversing drum diameters of just 10 mm

The Prosan™ conveyor belts have very flexible tension members. Small end drum diameters of just 10 mm are possible despite the polyurethane coating on both sides. As a result, these belts are a hygienic alternative to belts coated on one side where contaminants could penetrate the belt from the fabric on the bottom.