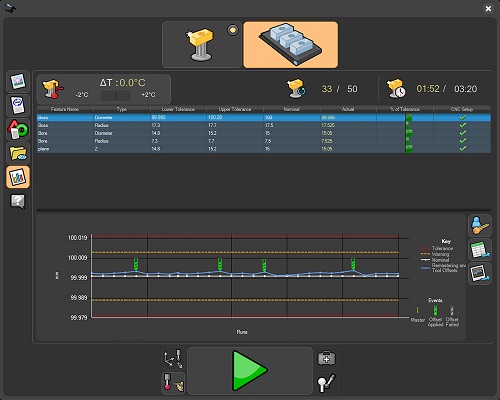

IPC offset updates being applied to a manufacturing process using Equator gauging data displayed in the Process Monitor view – the green icons show the point at which an update is applied

The Renishaw Equator flexible gauge is now offered with IPC (intelligent process control) software, providing the functionality to fully automate tool offset updates in CNC manufacturing processes.

According to the company, IPC is used with the existing software running on the Equator controller, using recent historical gauging data to determine process corrections. Connection to a compatible machine tool can be as simple as connecting an Ethernet cable from the Equator to a CNC machine. This capability has already been used by Renishaw customers worldwide to achieve considerable performance gains across a wide variety of industries, applications and CNC machine types, including lathes, machining centres and highly automated machining cells.

Controlling processes with frequent gauging

Renishaw explained the new IPC software allows constant monitoring and adjustment of a machining operation, keeping part dimensions close to nominal and well within process control limits. This means that any process drift is quickly corrected, improving part quality and manufacturing capability, along with reducing scrap. The proximity of the Equator gauge to the CNC process allows rapid measurement and process adjustment at the point of manufacture, avoiding time delays or relying on finished part (tailgate) inspection.

The IPC software can average results across several parts to determine the true process mean for adjustment of each cutting tool, they added. For process control purposes, it is usual that only one machined feature per tool offset will require gauging, as compared to many features for typical Quality Assurance (QA) applications. The frequency and control of offset updates can be configured on a feature by feature basis depending on design tolerances, process variation and tool wear rates.

Reduce dependence on skilled operators

Renishaw further explained the ability to correct a process automatically with IPC software eliminates the potential for manual data entry errors and removes the requirement for an expert to decipher traditional measurement reports into a process correction value at the CNC machine.

One-to-one or One-to-many – update multiple machines from one Equator gauge

An Equator gauging system can be connected to one or multiple CNC machine tools, so that parts from different machines can be gauged on one Equator, with the offset updates being sent to the corresponding machine (part / machine identification is required), the company said. Connection to multiple machines requires an Ethernet hub or is via an existing factory network. Closed loop unmanned process control of a cell of machines is possible and a key requirement when used in conjunction with factory automation systems.

Intelligent process control of cutting tools

Options within the IPC software can constantly monitor the process and detect excessive tool offset update values, indicating tool failure or high rates of wear, and automatically signal to the machine that the tool needs changing.

Where IPC software is of benefit

IPC software has proven to be particularly useful for conventional CNC lathes or Swiss-style sliding head machines where integration of a conventional machine tool probing system may be difficult due to machine configuration or tool station availability. Using the Equator gauging system is also beneficial where measurement due to feature access or size would be difficult to undertake on the machine tool. Also, the use of off-machine gauging and IPC as a parallel activity is the preferred solution where minimum machining cycle time is a critical requirement.

IPC compatibility

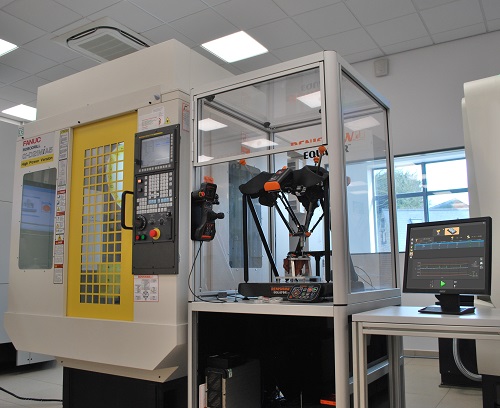

Moreover, Renishaw said the first release of the new IPC software allows connection to one or multiple machine tools, with direct Ethernet links from the Equator Controller to Fanuc, Mazak and Okuma CNC controls.

Fanuc controls that have been tested and proven include the 0i, 30i, 31i and 32i, with the Focas2 option installed. Mazak controls currently supported are the Smooth X, Smooth G, Matrix2 and Matrix controls with the Mazak API installed. The Okuma OSP300L and OSP300M controls are supported, on machines with the Thinc API installed. Future software releases will further increase CNC control compatibility.

The versatile gauge

Finally, the company said the Equator gauging system is unique in its design and method of operation, and has already changed the thinking of thousands of production engineers, making it their gauge of choice. The versatility and repeatability that Equator offers is re-defining the world of gauging and, now available with IPC software, it offers an even wider range of capabilities to manufacturers globally.

Equator gauge being used to update the machining process on a Fanuc Robodrill fitted with a Fanuc 32i control with Focas2 option

NEW BALANCE