The new range includes square shank holders for external applications, boring bars for internal applications and GL-heads for use with Steadyline bars.

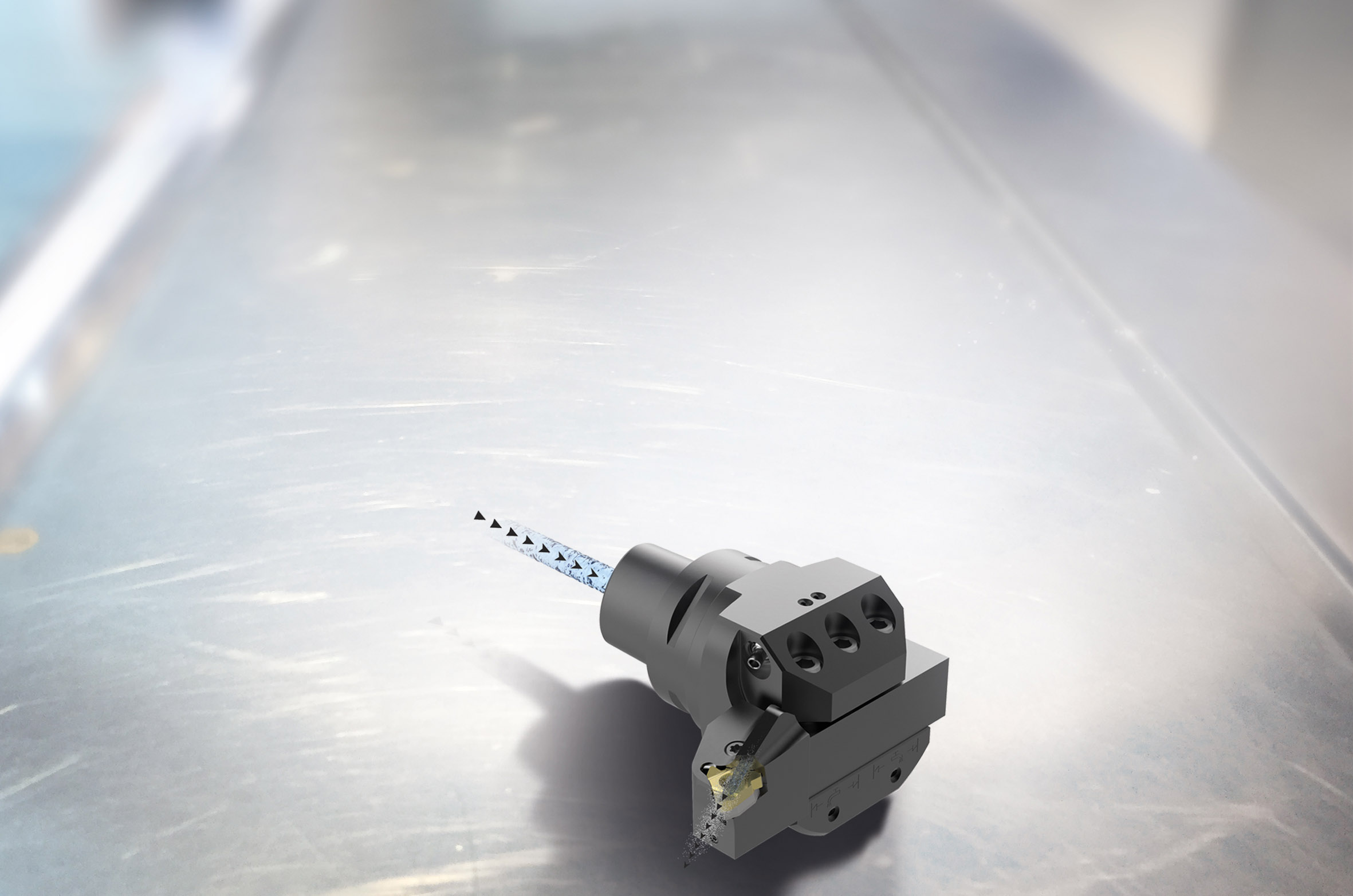

The Jetstream Tooling threading turning holders deliver a concentrated high-pressure jet of coolant - up to 150 bar/2,175 psi or hose connections for up to 275 bar/3,988 psi coolant inlets - to the optimum position close to the cutting edge making it possible to guide or steer chips a certain direction away from the cut. The toolholders are available in 22 external, 28 internal and 14 GL-heads types in insert pocket sizes 16, 22 and 27.

For parts made from titanium or similar materials, Jetstream Tooling technology is capable of breaking the tough threading chips to increase tool life. When threading steel and stainless steel, the improved chip control of the new thread turning tools allow for potentially 30 percent to 60 percent higher cutting speeds without compromising thread surface quality.

The square shank holders also include the JETI and Duojet features. JETI delivers coolant through holders without using a hose connection, and DuoJet applies one or more additional coolant jets from a second direction. Incorporation of these features brings optimized heat removal, effective chip elimination, longer and more predictable tool life and enhanced thread surface quality to thread turning operations.

Use of the JETI feature with square shank holders requires the use of adapters. The new range includes both face mount and star mount adapters for Seco-Capto™ C5, C6 and C8 turrets and star mount adapters for HSK-T 63 multi-tasking machine spindle interfaces. The adapters accommodate square shank sizes 20 mm and 25 mm.