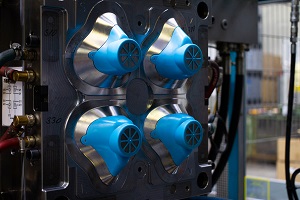

KB Backhaus GmbH, a specialist in manufacture of plastic components for automotive industry, has expanded its manufacturing within a very short time to include series production of face masks. An innovative 4-cavity injection molding tool with a special mold has been developed for this purpose, which enables a production capacity of 12,500 face masks per day.

The plastic material used was carefully selected during the production trials and are based on the thermoplastic elastomer SEBS. The material is durable, recyclable and also food-grade. At the moment, trials are also being conducted to treat the plastic with antibacterial additives.

The so-called community masks have already obtained a PPE special approval and are currently in the process of being certified with FFP2 protection class (CE 731943). In contrast to the traditional one-way or pure cotton cloth masks, the community masks of Backhaus can be used for almost an unlimited period of time. For the necessary filtering of the breathing air from droplets and aerosols, the wearer just places a cotton pad or a suitably cut piece of cotton material in the opening provided for it in the mouth area and fixes it using the supplied clamp ring. The mask can be cleaned quickly and easily using a disinfectant material, with soap and hot water or in the dish washer.