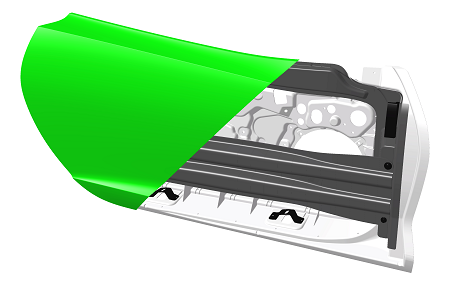

Teijin Limited's automotive composites specialty groups have developed a multi-material composite automotive door concept that maintains required crash specifications while reducing overall weight by 35% when compared to a conventional steel door. Jointly developed by Teijin Composites Innovation Center (TCIC) and Continental Structural Plastics Holdings Corporation (CSP), the prototype of this unique concept will be on display in the Teijin Group booth (hall6, G28 & J28) at JEC World 2019, taking place March 12-14 in Paris.

The module is made from carbon fiber sheet molded compound (SMC), glass fiber SMC and unidirectional glass fiber reinforced plastics (GFRP) to offer both high strength and low weight. Additional benefits include cost efficiency equal to that of an aluminum door module, and the ability to achieve deep draws and superior design freedom not achievable with a metal. The solution also withstands the heat level of the conventional E-coat automotive painting process.

Tough, lightweight, eco-friendly modules are increasingly being adopted, especially in Europe, for automotive components such as resin-based tailgates, bonnets (hoods) and roofs to help reduce CO2 emissions and further the range of electrical vehicles. Multi-material side-door modules for high-volume vehicles have been realized by some automakers, however, they still are particularly challenging for designers as these components must meet especially demanding requirements for shock absorption to protect passengers in crashes, fatigue resistance to withstand the stresses of repeated opening and closing and accommodate interior harnesses for electrical wiring and signal components.

Teijin plans to continue enhancing the quality of its side-door module capabilities by applying various high-performance materials and technologies available within the Teijin Group. Leveraging its strengths in composite technologies, the goal is to launch a commercial door module by 2025 and become known as a global supplier of multi-material automotive components, targeting sales worth approximately $2 billion by 2030.