battenfeld-cincinnati is introducing to the GCC market its new, high-quality extrusion equipment. The machine manufacturer’s latest developments strongly focus on efficiency and industry 4.0 issues that are currently particularly important to the plastics industry. These developments include the two new extruder series solEX NG and conEX NG for the production of pipe as well as the FDC (fast dimension change) systems for ultimate flexibility in diameters and wall thicknesses. For thermoforming sheet production, several high-speed extruder models are available along with the latest XXL version of the Multi-Touch roll stack, designed to address the worldwide growing market for packaging sheet.

“Next Generation” extruder series for PO pipe production

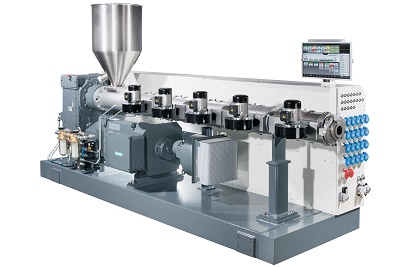

The new single screw extruder solEX NG (NG = Next Generation) series has been developed on the basis of the proven solEX series. The extruder features a completely new processing unit offering a multitude of advantages, such as a much lower melt temperature with excellent melt homogeneity and mixing quality, less energy costs and longer lifetimes of screws and barrels.

The new series is available in four sizes (60, 75, 90 and 120 mm) and offers outputs ranging from 1,000 to 2,500 kg/h – an increase of up to 25% for each machine size compared to the original solEX series. With this, battenfeld-cincinnati again sets a new benchmark in the market in terms of output and energy consumption.

New conEX NG extruder series for PVC materials

In addition to the new solEX NG series, battenfeld-cincinnati also presents the “Next Generation” conical twin screw extruder series conEX NG. This series consists of three models that have been completely re-designed in terms of process technology. With outputs from 60 to 450 kg/h for PVC pipe, it offers maximum productivity.

Also, the new geometry concept ensures a balance between mechanical energy input over shear and thermal energy input, which increases the bandwidth of PVC-based materials to be processed. This minimizes machine wear and simultaneously ensures that a great variety of material blends can be processed with just one screw configuration. Therefore, the new conEX NG series fulfills all current demands of the global extrusion industry for the flexibility required to produce a wide range of different high-quality products at low cost.

Speed, efficiency & cost savings

With the FDC system, automatic pipe diameter changes within a specified range are possible during production. This enables pipe producers to gain enormous production flexibility, making this the greatest advantage of the new line. In addition, energy costs can be reduced and immense material savings can be achieved thanks to much shorter changeover times. In addition, the extruder control system has been extended, so that the changeover of all components up to 630 mm of pipe diameters can be effected at the push of a button.

battenfeld-cincinnati is also a leading manufacturer of complete, high-speed extrusion lines for uPVC pipes. Space-saving quadruple strand configurations for dimensions from 50 – 250 mm with a throughput of up to 1,600 kg/h are offered.

battenfeld-cincinnati has proven in the past that with its powerful high-speed extruders, the STARextruder series specifically for PET extrusion and its unique roll stacks is optimally prepared for the growth market of packaging.

The latest generation of the Multi-Touch roll stack in the XXL version (MT O60 2+3+2-190) has recently been presented at the K-show in Germany. This Multi-Touch model delivers an enormous output of up to 3,300 kg/h (PET) and up to 2,700 kg/h (PP) depending on the width and thickness of the sheet, while at the same time there are no compromises in sheet quality. Multi-Touch roll stacks work with a combination of two rolls for pre-calibration and three, five or seven rolls in post-calibration. So they produce stress-free sheet with thickness tolerances of +/- 1% even at high line speeds.

battenfeld-cincinnati booth at Arabplast is located at the German Pavilion: hall 5, booth 6B100

Related Links: