The LASER EX Series represent the world's first multitasking machines that perform milling, turning, and grinding, as well as hardening and additive manufacturing processes.

Laser metal deposition (LMD) with a variable laser achieves precision control, from high efficiency to high definition additive manufacturing. Laser spot diameter: ø0.4 to 8.5-mm (infinitely variable control).

Adding hardening to the cutting and grinding processes. Compared to hardening in conventional heat treatment systems, this process is quick and produces less distortion resulting in dramatically improved throughput.

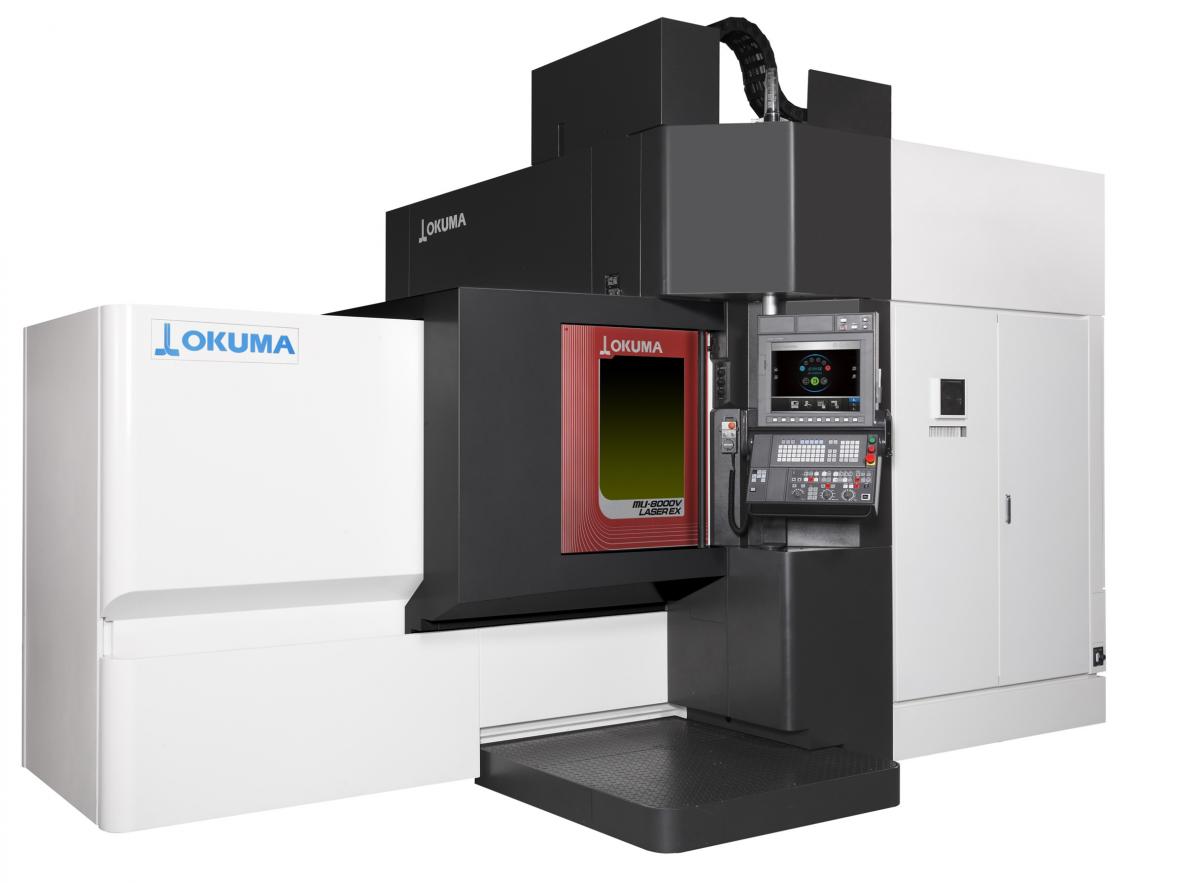

Five models are in this LASER EX series now for a wide range of workpieces. The MU-8000V, MU-6300V, and MU-5000V are based on vertical machining center 5-axis machines. The MULTUS U3000 and MULTUS U4000 are based on Okuma’s multitasking machine design.

The MU-8000V LASER EX for ø1,000-mm parts, is the world's largest machine for additive manufacturing.

OKUMA Corp.

Tel: +81-587 957825

Fax: +81-587 956074

Website: www.okuma.com

Nike Air Max 2017