Nordson Corporation has developed a digital tool for comparing the cost inputs of standard sheet dies with removable lower lips and those of the EDI® SmartGap™ mechanism for rapidly changing sheet thickness.

The tool, SmartGap Payback Analysis, enables sheet manufacturers to calculate the payback time for switching to SmartGap technology. It can be accessed online at http://www.nordson.com/en/divisions/polymer-processing-systems/support/calculators.

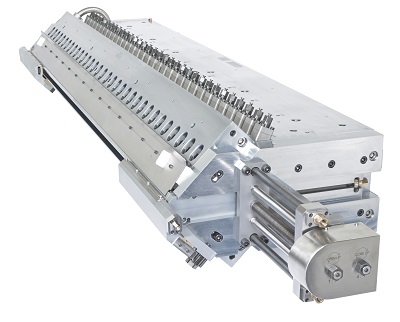

SmartGap technology enables manufacturers to make changes in thickness with unprecedented speed, extend the range of thicknesses that they can produce, and achieve these improvements while enhancing sheet quality. The system uses a single-point adjustment mechanism that changes the lip gap while simultaneously modifying the length of the lip land to provide the most appropriate conditions for the newly adjusted thickness as the sheet exits the die. By mechanically linking the adjustment of these two key process variables, the SmartGap system ensures a proper set-up of the die and takes substantial time and guesswork out of the process for achieving desired sheet properties.

SmartGap technology enables manufacturers to make changes in thickness with unprecedented speed, extend the range of thicknesses that they can produce, and achieve these improvements while enhancing sheet quality. The system uses a single-point adjustment mechanism that changes the lip gap while simultaneously modifying the length of the lip land to provide the most appropriate conditions for the newly adjusted thickness as the sheet exits the die. By mechanically linking the adjustment of these two key process variables, the SmartGap system ensures a proper set-up of the die and takes substantial time and guesswork out of the process for achieving desired sheet properties.

Users of the SmartGap Payback Analysis enter two types of information: 1) the one-time costs of equipment investment for a standard sheet die with removable lower lip and for a new SmartGap system; and 2) process data including die length, output rate, number of die gap and die lip changes, number of working days, raw material cost, approximate product selling price, and burden cost of sheet line per hour.

Using these inputs, the tool calculates the daily output values of the two systems, including downtime, missed production output, downtime cost, missed product gross profit, and total downtime cost; compares the time required for changing die lips versus that needed for changing the die gap in the SmartGap system; and estimates the how long it would take for a complete return on an investment in the SmartGap system.

Payback typically occurs in a matter of months, according to Sam G. Iuliano, senior technical manager for Nordson’s EDI brand.

“The SmartGap system eliminates the extended shutdowns for changes in lip components that have often been necessary when transitioning to new job runs, reducing to a matter of a few minutes changeovers that used to take two hours or more,” said Mr. Iuliano. The system also overcomes previous limitations on thickness range caused by the complexities of die modification; the SmartGap system readily encompasses die gap adjustments over a range of 0.400 in. (10.2 mm), enabling processors to efficiently run with multiple product changes per day, Mr. Iuliano added.

Ni?o/a