WITH Vietnam envisioning industrialisation by 2035, the food and beverage industry has become among the top priorities of the government. But F&B manufacturing sector consisting of 8,800-plus companies, has yet to play catch up in terms of increasing production capability and know-how. This is no surprise as close to 85% are relatively small. Thus, the opportunities for improvement are everywhere –food quality, safety and hygiene, product development, waste reduction, as well as in packaging and recycling.

Ringier Events through its first run of the ASIA Manufacturing: Food, Beverages & Packaging Summit in Ho Chi Minh City, successfully linked 180 participants from Vietnam, mainland China, Hong Kong, Taiwan, Thailand, the Philippines, and other countries.

The conference at the Pullman Saigon Centre hotel from 7-8 May 2019 was supported by the Food and Foodstuff Association of Ho Chi Minh City, The Vietnam Packaging Association, The Packaging Council of Singapore, and the Hong Kong Food Professionals Association.

Two-day conference in Vietnam, Asia Manufacturing: Food, Beverages & Packaging Summit, gathered 180 participants from the food and packaging sectors across Asia.

Sponsors of the event were Chang Woen Machinery (silver sponsor), Dase-Sing Group, Hantech Bio-Technology Co. Ltd. (liquid and jelly functional foods), Shanghai Precise Packaging Co., Ever Polymer Co Ltd, Guangzhou Juhang Machinery Equipment Co., Ltd., Guangzhou Fander Mechanical And Electrical Co. Ltd, Guangdong High Dream Intellectualized Machinery Co., Ltd, Kinn Shang Hoo Iron Works, Gen Asia Biotech Co., Ltd, and Printpack Inc.

A market unfolding

The challenges and opportunities are unique in every market. Vietnam's determination to modernize its economy brings along opportunities for industry development and expansion. As the economy improves, the social stratification is therefore changing. The upper middle-class will soon dictate food and beverage preferences. The desire for higher quality food will increase as consumers are willing to pay more for products perceived as safe, of high quality, and made with natural and healthy ingredients. The demand for healthier products will push the growth of herbal teas, fruit juices, and other nutritious drinks, while the love for beer will see the per capita consumption rise to 42 litres in 2020. Local beverage consumption is expected to reach 109 billion litres in 2020, according to a report by the EU-Vietnam Business Network.

Resource speakers at the Asia Manufacturing: Food, Beverages and Packaging Summit hoped to address several industry needs with solutions for processing, sustainable packaging, connectivity, and the application of innovative ingredients for manufacturing higher value products.

In his presentation, Saponti Baroowa, associate director at Dezan Shira & Associates, highlighted what to expect when investing in Vietnam. He said the growing appetite for high quality, safe and convenient foods will be met by production of gourmet and fine foods and additive-free products, as well as packaging that resonate with green living. And as the government prioritises the F&B industry, strict requirements on used equipment and machinery coming into the country as well as more stringent regulations and certifications for imported frozen food, re-exports, and additives, will be in place.

Supporting this fact, TUV Rheinland Vietnam project manager Dao Thuy Khanh Linh gave an overview of regulatory compliance in food packaging materials, explaining the local and international requirements for food contact materials. This is very important in ensuring product safety.

Turning discarded fruit parts into edible products

One of the major takeaways from this conference is the emphasis on developing healthy products and reducing waste at the same time.

Dr Thien Trung Le, head of the Department of Food Engineering at Nong Lam University, and CEO of the start-up Nong Lam Food provided samples of fruit peels processed into snacks. His extensive knowledge of such technologies as membrane separation, microwave processing, irradiation, and extraction of bioactive components has given rise to his company’s production of fruit peel snacks (pomelo and orange rinds) that are extremely high in antioxidants.

Dr Thien Trung Le, head of the Department of Food Engineering at Nong Lam University, and CEO, Nong Lam Food

Another speaker, Lai-Ying Fong also touched on the process of turning orange peels into edible products. Ms Fong is associate professor at the Technological and Higher Education Institute of Hong Kong.

Lai-Ying Fong, associate professor,Technological and Higher Education Institute of Hong Kong

The goal to extend product freshness

Extending product shelf life directly benefits the supply chain, from suppliers and manufacturers to consumers, because products can be stored or consumed for a later time. The goal is now to use natural ingredients to achieve freshness longer. This was the topic of Ms Man Ka Mun’s speech during the conference. A lecturer at the Hong Kong Institute of Vocational Education, as well as chairperson of the Hong Kong Food Professionals Association, Ms Man presented the value of using antimicrobials or edible coatings and films to increase food shelf life.

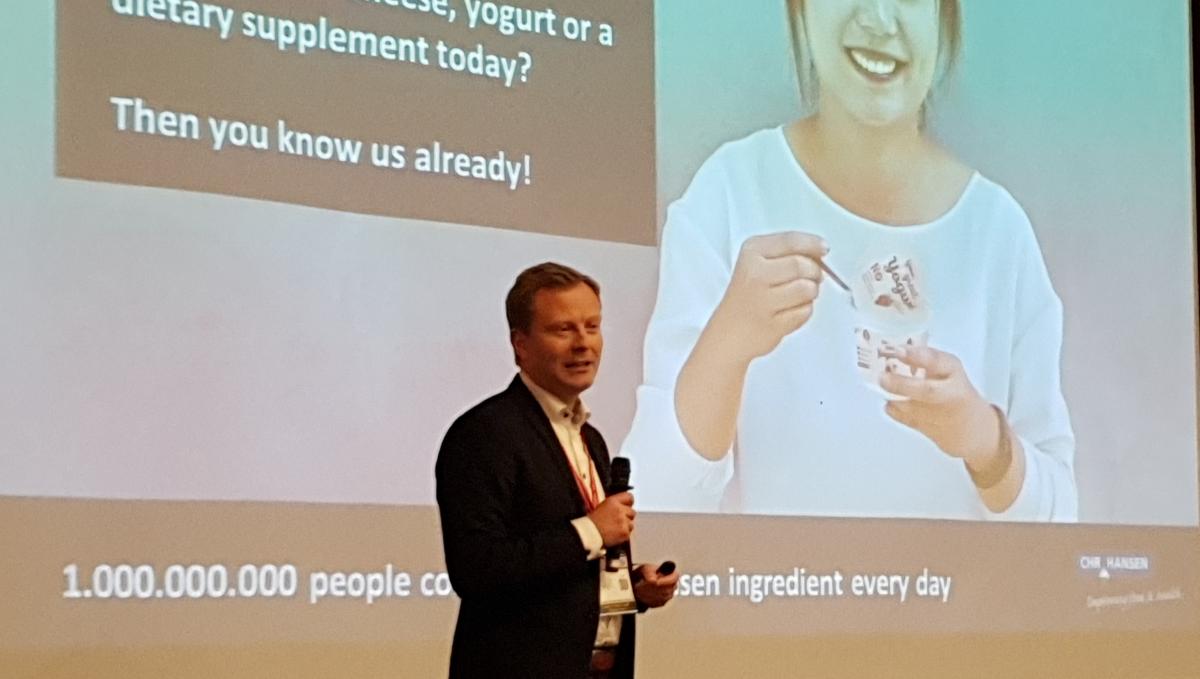

Expounding on the same topic, Peter Thoeysen, commercial director for Bioprotection at Chr. Hansen in Denmark, presented on the use of antimicrobials and company’s wide-ranging products for bioprotection that all benefit foods like yogurt, cheese, and meats.

Peter Thoeysen, commercial director for Bioprotection, Chr. Hansen

Apart from the addition of certain ingredients, food or beverages can remain fresh for a longer period through better packaging. In his presentation, Mr Jurgen Willems, general manager of Printpack (Suzhou) Packaging Co. Ltd, explains the barrier technologies for flexible and rigid packaging that allow for longer product freshness and safety. Such packaging is also microwaveable, lightweight, printable, and does not require cold chain.

Mr Jurgen Willems, general manager, Printpack (Suzhou) Packaging Co. Ltd

Packaging developments

Vietnam’s packaging sector is keeping pace with F&B market developments, and steadily growing at 10%. A major challenge for this sector is how to address cost, as packaging can account for 50% of a product. Other concerns are related to sustainability efforts, keeping up with design trends, and investment in new equipment and automation.

Discussing trends in these industries, Teri Teo knows both markets very well as he is director of Learth Group as well as business development director of PS Food & Beverage Pte Ltd in Singapore. His speech was focused on how trends in the packaging and food and beverage markets are interweaving. He cited demand for traditional tastes and flavours, plant power, and convenience as major F&B trends, while in packaging, demand is for those that meet functional, green, and convenience features. He also said more lightweight materials are replacing metal packaging.

Another trend is glowing labels, according to Tony Huang, executive assistant at Dase-Sing Packaging Technology, a sponsor of this conference. Mr Huang also shared his company’s manufacturing capability for shrink sleeves, a number of which are used by leading F&B manufacturers.

Tony Huang, executive assistant, Dase-Sing Packaging Technology

Taiwan’s Ever Polymer Co. Ltd, a sponsor of this event, discussed the advantages of their products including the innovative Easy Peel multilayer film for food packaging. The soft, non-sticky FDA-approved product has four layers made of adhesive, PET/PA (printing layer), PET (structural layer), and sealant layer. It is suitable for products including yogurt drinks with heat-sealed caps, edible oils, condiments, medicines, milk, water and juices.

Expected to be relevant for years to come, sustainability now ranks higher on every F&B stakeholder’s agenda. In packaging, while plastic is still shrouded with misconceptions, it will remain a big part of the F&B market.

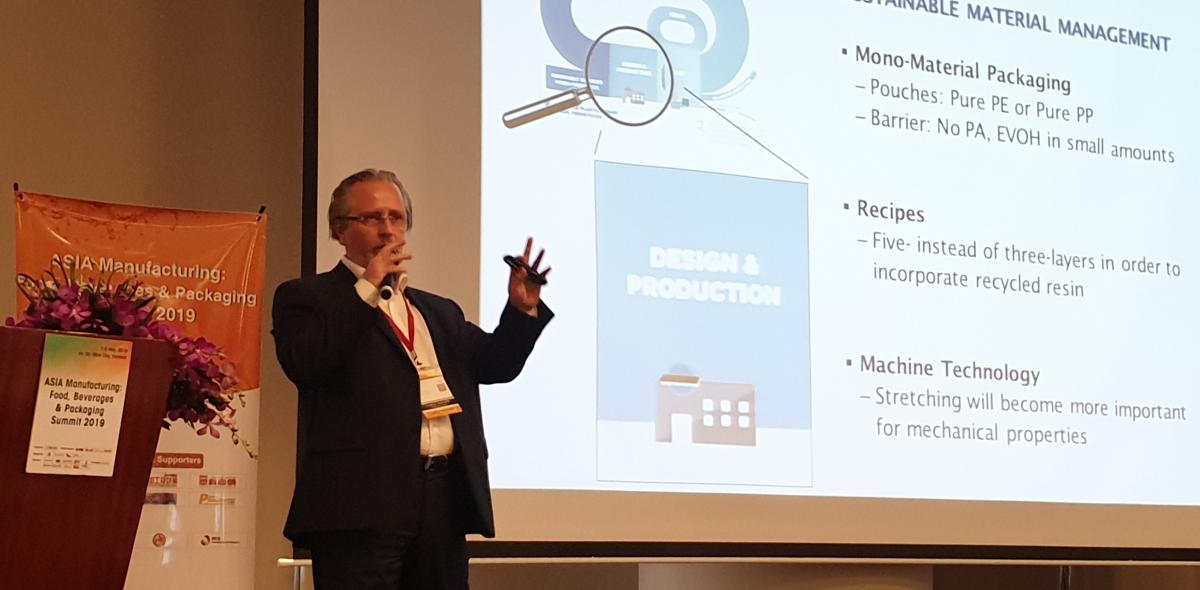

Juergen Rehkopf, managing director at Reifenhauser Singapore

According to Juergen Rehkopf, managing director at Reifenhauser Singapore, what’s necessary is a circular plastic packaging alliance and cooperation within industries to build the sustainability of supply chains. Reifenhauser, which is known for its strong R&D capability and plastics extrusion technologies, advocates green packaging use.

Mr Rehkopf’s speech coincides with a presentation by Ted Kao, vice-president of global sales for Chang Woen Machinery. During the summit, Mr Kao helped raise awareness on how companies can fully recycle their PET into PET products that are still safe for food and beverages. The option is quite viable, and is being used by companies in Taiwan and Thailand, according to Mr Kao.

Ted Kao, vice-president of global sales for Chang Woen Machinery

The future of factories

Man and robotics working more seamlessly together will move industries forward. By 2020 all products will have connectivity through products like sensors, stressed Bosch Rexroth general manager Nicolay Kurnosov during his speech. While concerns such as those relating to machines replacing humans in the workplace are not uncommon especially in Southeast Asia where factories rely on manual work, the success of a company will be latched on its ability to adapt to robotics and automation. Mr Kurnosov allays such fears and emphasizes that progressive companies – those that show they can be innovative with support from new technology, highly resonates with customers, and attracts even more customers.

Nicolay Kurnosov, general manager, Bosch Rexroth

Food safety and traceability

Beyond innovation, the use of automation is especially vital for helping companies manage food safety and traceability. Ms Ly Kim Chi, chairwoman of the Food and Foodstuff Association of Ho Chi Minh City addressed this issue during her presentation. Ms Ly who is also the CEO of Tan Dong Hiep Group and Nam Long Trading Construct Co. Ltd, reminded conference delegates that Vietnam’s F&B industry should tap its potential in order to drive exports and “to re-assert its position in the international market.” In order to raise their competitiveness, she recommended participants to invest in automated technology.

Ms Ly Kim Chi, chairwoman of the Food and Foodstuff Association of Ho Chi Minh City

Safety not only of finished products but in the workplace and in packaging operations was the focus of Dr Elaine Borazon’s presentation during this summit. Dr Borazon is currently assistant professor at the College of Home Economics in the University of the Philippines, and the president and CEO of BusinessBests InnovaCon, a consultancy firm for food companies. She explained the various requirements necessary in safety management.

Dr Elaine Borazon, assistant professor at the University of the Philippines, and CEO of consultancy firm BusinessBests Innovacon.

Products to watch

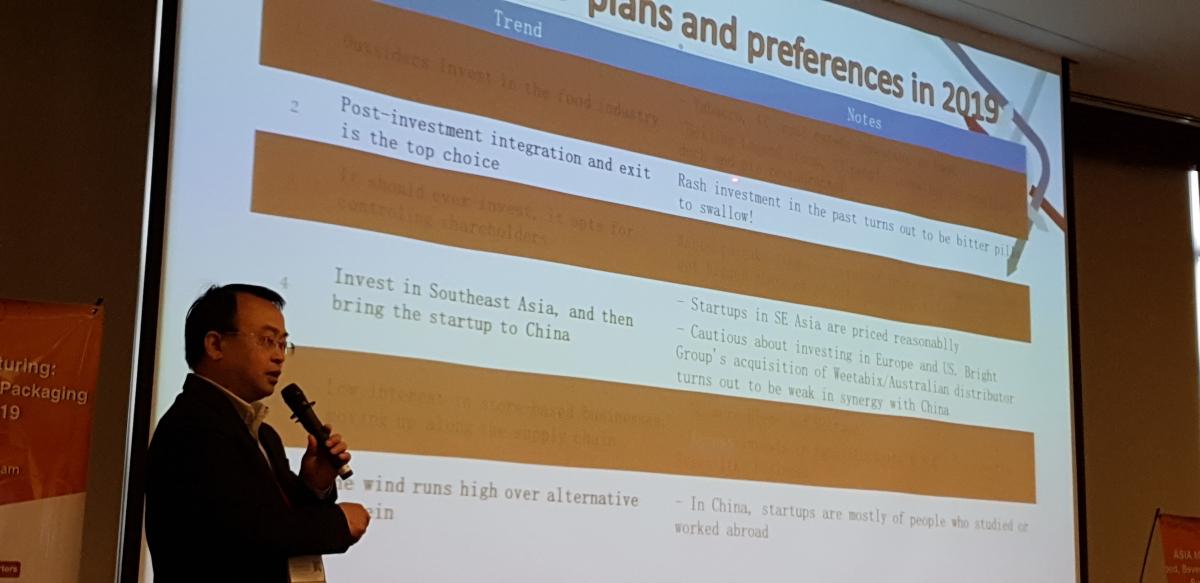

One of the hottest products in the food and beverage market is alternative proteins, or those coming from plants. China is one of the largest markets for plant-based proteins coming from soy and grains, and Southeast Asia is catching up as well. According to Sam Gao, the co-founder and senior analyst of Topguide Advisory Shanghai, this segment is rapidly growing. Drawing interest from consumers are plant proteins as well as alternative or synthesized meats.

Sam Gao, co-founder and senior analyst, Topguide Advisory Shanghai

Coffee consumption in Asia, and specifically China has surged dramatically, and just by relying on the number of coffee houses mushrooming in cities in the last 10 years, it is safe to say coffee has found a new place to grow in the region. Sharing her experiences as founder of a coffee company in Taiwan, Regina Lian of Reginalian Fine Roasted Coffee, inspired participants with her success story – of how she was able to enter the China market and see ROI in just a year.

Natural dairy products such as cheese and milk are gaining popularity in countries like Indonesia and the Philippines. For this summit, R&D supervisor of Dairy Technologies Corp, Irenelle Medalla was invited to speak on a simplified R&D product development approach in a dairy manufacturing business. Ms Medalla provided a to-do list and checklist of the requirements. A licensed nutritionist and dietitian, Ms Medalla, a led the development and pilot scale production of ChocNut Choco-Peanut Spread for Annie Candy Corporation in the Philippines.

Irenelle Medalla, R&D supervisor, Dairy Technologies Corp

Hantech Bio-technology Co, Ltd, a sponsor of this event, presented their expertise in OEM and ODM for liquid and jelly functional foods, all of which are made with natural ingredients and come in different pouches. Their nano-grade Pearl powder and Guilu powder feature bioavailable calcium, amino acids, and trace elements.

Visit to Inoac Polymers Vietnam

Delegates had the opportunity to meet vice general director, Masahiro Iyo and other members of Inoac Polymers Vietnam, as well as tour the facilities for materials produced based on polyurethane, rubber, plastic and synthetic materials. Participants were especially interested in the company's series of cold transport containers made with aluminium and polyethylene foam and with up to 50kg tensile strength. In various sizes such containers can be used for delivery of small or large amounts of milk, foodstuff, pharmaeuticals, and for food service and supermarkets.

Networking during cocktails

At the end of the first day, participants had the chance to unwind with some drinks and hors d'oeuvres, soak up the city skyline view from the 30th floor of Pullman Saigon Centre, and of course to catch up with the day's presentations as well as network!