ATOS Compact Scan

With its full-field and non-contact 3D measuring technology, GOM provides a decisive basis for Industry 4.0.

Mobile metrology

Today, due to increasingly shorter production and development times, the inspection of tools, systems and parts directly takes place during the ongoing production. GOM responds to this challenge of industry with mobile and flexible measuring systems that can be used directly on-site of the measuring object.

For online measurement and part positioning, GOM provides a mobile optical 3D measuring system that enables an assembly analysis basing on augmented reality. Using dynamic referencing, the part and the sensor can be moved freely – regardless of the interferences in a production environment. PONTOS Live also allows the combination of optical and tactile measuring procedures.

For mobile 3D digitising, GOM has developed the compact class of the ATOS series. ATOS Compact Scan excels by its flexibility: System, stand and laptop fit into one suitcase and can be transported easily. Due to its changeable measuring areas, the robust and precise sensor enables digitising and inspection of small parts up to large tools. Depending on the requirements, the sensor’s accuracy and resolution can be adapted flexibly.

When inspecting large-volume objects such as industrial plants as much flexibility as possible is required – therefore, GOM offers the TRITOP system, a coordinate measuring machine that captures single 3D coordinates of large-volume objects fast and precisely. The system is used hand-held and wireless. The measurement can be evaluated immediately on the laptop. This guarantees the fitting of parts prior to the assembly.

Measuring data for Industry 4.0

The most important measure for optimising manufacturing processes in tool, pattern and mold making, is quality assurance, involving measurement, control and correction processes. To do so, three-dimensional digitising of the actual states of finished and semi-finished products, tools and machines has formed the respective basis.

For Industry 4.0, the use of digitised 3D measuring data offers complete new possibilities. A number of new manufacturing and repair technologies have emerged from the combination of full-field coordinate measuring points and current CAD/CAM software.

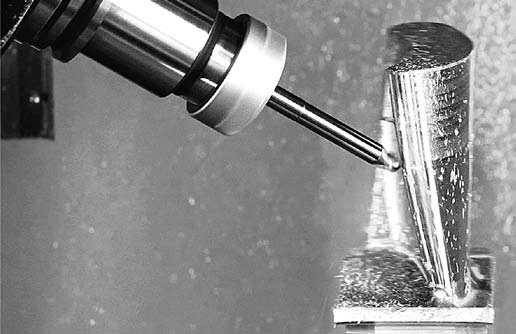

In adaptive machining, 3D measuring data of the ATOS system is already used for automated adjustments of single manufacturing and repair steps. Based on the actual states, CNC programs and traveling paths are calculated such that parts are manufactured according to nominal dimensions. In the long term, the whole process control could be based on 3D data. A prerequisite is the establishment of standardised interfaces for software and hardware.

New standards

In concepts such as PLM (Product Lifecycle Management), as much process and part information as possible is gathered in the form of PMI (Product Manufacturing Information) to ensure a comprehensive and company-wide management and control of production chains. Therefore, GOM already developed interfaces for the digital transfer of inspection features. Quality criteria and datum systems that were implemented by a semantic construction into the CAD, can be transferred digitally and evaluated in a context-sensitive way. Integrating standardised inspection languages such as GD&T into the GOM Inspect software is a further contribution from the company to Industry 4.0. Furthermore, new interfaces were developed which will allow a simple and robust communication between the plants and measuring systems in the future.

Automated quality control with 3D measuring machines

In response to growing quality requirements and the need for faster measurements at the same time, companies are now opting for automated measuring and inspection systems. On account of this trend, GOM has introduced its optical 3D measuring machine ATOS ScanBox during the EMO Hannover 2017.

In the standardised measuring cell, the entire measuring and inspection procedure, including the inspection report, is automated. Once the measuring procedure has been saved, even employees who have not any prior knowledge in metrology are able to operate the system. The nine different models of the series are suited to different sizes of the parts.

The ATOS ScanBox is not localised, but can be set up and put into operation within one or two days. The core of all measuring cells is a robot-driven 3D scanner of the ATOS series, which is used for non-contact and three-dimensional measuring of parts. The standard software solution virtual measuring room (VMR) simulates the real measurement cell environment, making it possible to display movements during the measurement process in virtual simulations. Thus, the robot can be controlled via drag & drop commands without a control panel. The measurement and inspection process can be prepared based on CAD data without the need for a real part.

The ATOS ScanBox models have been developed specifically for production-related inspection and quality assurance processes, and are already used by numerous enterprises including Daimler, VW, Rolls-Royce, Bosch, Honeywell, Samsung, Automotive Lighting and ZF. In their industrial production facilities, the measuring cells achieve high throughput rates, since more parts are analysed in a shorter time. Furthermore, the measurement cells achieve high reproducibility and, at the same time, process reliability, since measurement and inspection processes are deployed at different locations without a user.

Precise industrial 3D metrology

GOM develops, produces and distributes software, machines and systems for industrial and automated 3D coordinate measuring technology and 3D testing based on latest research results and innovative technologies.

With more than 60 sites and an employee network of more than 1,000 metrology specialists, GOM guarantees profound advice as well as professional support and service to operators on-site in their local languages. In addition, GOM shares knowledge on processes and measurement technology in training courses, conferences and application-based workshops.

GOM has been developing measuring technology in Braunschweig since 1990. In the respective research and development departments, more than 100 engineers, mathematicians and scientists shape the measuring technology of the present and the future.

Today, more than 10,000 system installations improve product quality and accelerate product development and manufacturing processes for international companies in the automotive, aerospace and consumer goods industries, their suppliers as well as many research institutes and universities.

Airfoil adaptive-manufacturing

Off White X Max 180-90