The quality of workpieces produced with additive methods is also increasing as is machining speed. This has resulted in consistently positive forecasts: additive manufacturing is expected to grow by 20 to 30 percent by the year 2020.

“In particular as a complement to conventional production methods powder nozzle and powder bed processes offer expedient and extremely promising possibilities”, explains Patrick Diederich, responsible for Additive Manufacturing at DMG MORI.

With its broadly diversified machine portfolio in both machining and additive manufacturing DMG MORI’s approach to this topic is clearly holistic. Patrick Diederich goes on to tell us: “If additive manufacturing is to become established on the shop floor, it is essential to integrate this method into existing production systems and process chains – especially where successfully progressing from prototype and small series production to serial production is concerned”

Cost efficiency plays a key role in this respect. “It is imperative to awake an awareness for the possibilities offered by additive manufacturing, which start with the design of components and extend throughout the entire life cycle of the product,” he added. This is the only way to exploit its enormous potential.

The company has performed successfully on the market for over five years now with the combination of laser deposition welding and metal-cutting machining on the machines of the 3D hybrid series. In addition to establishing and expanding the digital process chain DMG MORI has also developed to become a full-liner in additive manufacturing. The LASERTEC 65 3D is geared solely towards laser deposition welding as a complement to existing machining centres on the shop floor, while the LASERTEC SLM series expands the portfolio to include the powder bed method using selective laser melting.

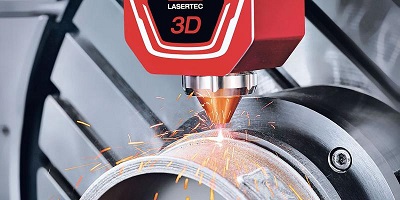

LASERTEC 3D hybrid: Additive manufacturing using a powder nozzle and conventional machining in a single set-up

The LASERTEC 3D hybrid and LASERTEC 3D machines are available for users in the field of laser deposition welding with a powder nozzle. The first combine additive manufacturing and conventional machining in a single set-up. The LASERTEC 65 3D hybrid is designed for the 5-axis simultaneous machining of parts measuring up to ø 500×400mm. The LASERTEC 4300 3D hybrid enables 6-sided turn & mill operations for workpieces with sizes up to ø 660×1,500mm. Designed for the complete machining of demanding geometries the LASERTEC 3D hybrid machines enable flexible changeover between laser deposition welding using a powder nozzle and mill or turn operations.

LASERTEC 65 3D: The right addition to the machines already installed on the shop floor

A second process chain based on the powder nozzle includes the compact LASERTEC 65 3D for 5-axis laser deposition welding and a machining centre for final finishing of the additively manufactured components. This makes the LASERTEC 65 3D the ideal addition to the machines already installed on the shop floor, a combination that ensures optimum utilisation of production capacity. With travel paths of 735×650×560mm the work area of the LASERTEC 65 3D is around 40 percent larger than the hybrid version and its footprint is about 45 percent smaller.

The company completes the process chains in laser deposition welding with NC programming in hybrid CAD/CAM with SIEMENS NX, technology parameters from a material database plus process monitoring and documentation.

“Different materials can also be combined in one build process in the two process chains with the powder nozzle, a capability that can give parts special properties”, added Patrick Diederich.

Jordan Flight Luxe