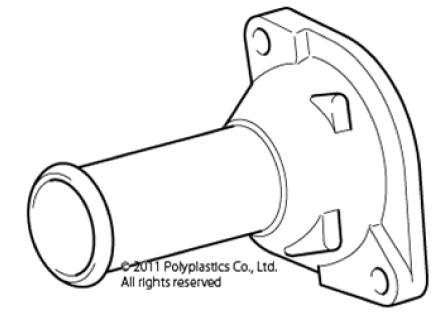

Polyplastics has completed an extensive study which confirms the viability of polyphenylene sulfide (PPS) for bump-off molding of automotive engine cooling systems. Polyplastics’ linear DURAFIDE® PPS, which already offers superior performance over rivals like nylon 66, now has bump-off molding capabilities to eliminate deburring.

Bump-off molding results in an undercut that “bumps” in two directions and ejects from the mold without using a sliding structure. The parting line (mold lip) goes away allowing for a burr-less mold. Previously, PPS had limited use in bump-off molding of engineering parts due to its fragility.

Polyplastics found that materials with high bending fracture strain in high-temperature environments (150°C for PPS) are suited for bump-offs in terms of both damage and deformation. The company also observed that improvements in fracture strain in high-temperature environments are possible by reducing filler, adding elastomer, and utilizing high-molecular-weight PPS.

Polyplastics has shown that linear PPS exhibits greater fracture strain than cross-linked PPS and is more conducive to bump-off molding. Polyplastics’ DURAFIDE® PPS appears to be suited for bump-offs from the standpoint of toughness in high-temperature environments. Among DURAFIDE® PPS materials, high-molecular-weight 1130A1 (GF30%) and 1140A1 (GF40%) appear to be useful for bump-offs.

Polyplastics believes that DURAFIDE® PPS boosts the reliability of products, and that bump-offs reduce the deburring process and facilitate greater design freedom. DURAFIDE® PPS also delivers high heat resistance with a continuous service temperature of 200°C to 240°C. It also offers greater chemical resistance versus fluoropolymers and greater dimensional stability and reduced hydrolysis and water absorption compared to nylon 66.

Air Force 1