The increasing use of high-strength and ultra-high-strength steel grades in automotive body press shops presents new challenges

Lead figure: Smooth process flow during forming by using Multidraw PL 61 SE: The figure depicts the inside door panel for a Fabia II model from a test series at Skoda.

Because of their enormous lightweight construction potential, and the general interest in saving material, the metal forming industry increasingly relies on high-strength and ultra high-strength steel grades. To help customers meet increased demands placed on press shops, the lubricant experts from Zeller + Gmelin have developed "Multidraw PL 61 SE", a 2nd generation prelube oil.

The increasing use of high-strength and ultra high-strength steel grades in automotive body press shops presents new challenges. Its VDA Working Group, responsible for forming lubricants, demanded an improved prelube oil. In essence, prelube oils are anticorrosion oils with additional additives, which can act simultaneously as forming oils in the press shop. In this market, Zeller + Gmelin's Multidraw PL 61 has been a successful prelube solution for many years. Requirements for a second prelube oil generation included, on the one hand, further good compatibility with downstream processes of the painted body and, on the other hand, the improved tribological properties, in particular, on hot-dip galvanized surfaces. We developed the new Multidraw PL 61 SE to meet precisely these requirements. Its application to the rolling mill allows press shops to operate without additional lubrication, which must be eventually removed through a cleaning process before painting.

PTU tool wear research

The Institute for Production Engineering and Forming (PTU) of the Technical University of Darmstadt has developed an analysis method that considers tool wear, as well as the associated tool life for set stress levels. This was implemented in parallel with a monitoring system to reduce the wear development analysis effort. During the test series with our proven Multidraw PL 61, we were able to perform an additional test with the new Prelube PL 61 SE. Researchers at PTU were able to show a significant improvement of Multidraw PL 61 SE over Multidraw PL 61. Specifically, the use of Multidraw PL 61 SE provides a significant reduction of tensile forces. Compared to the previous prelube oil, the tensile force under maximum stress dropped by nearly 11 percent, while decreasing by 7 percent as the stress went down by 10%.

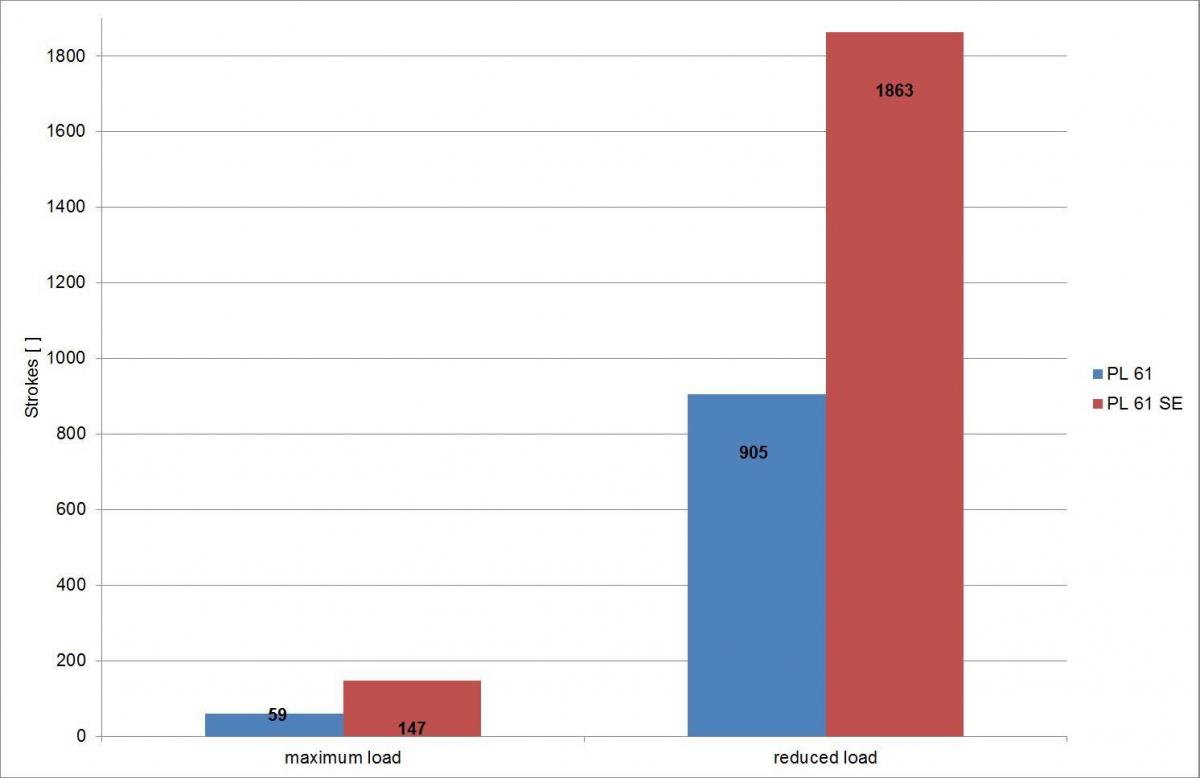

Under high stress conditions, there was a clear difference in service life up to the time of failure: In particular, Multidraw PL 61 withstood on average 59 strokes, while Multidraw PL 61 SE withstood 147 strokes for the same stress level. This corresponds to a 2.5 times increase in productivity. Under reduced stress conditions, service life increased 2.1 times. The reference PL 61 attained 905 strokes, while the new prelube oil reached 1863 strokes. Therefore, the absolute increase in tool service life is seen as a particularly important economic factor to raise productivity in press shops. Especially when one comes close to extreme stress levels, as evidenced during testing, an optimum lubricant with better additives significantly increases the carrying capacity, which brings measurable improvements in forming complex components.

Service life for Multidraw PL 61 & Multidraw PL 61 SE

Air Jordan