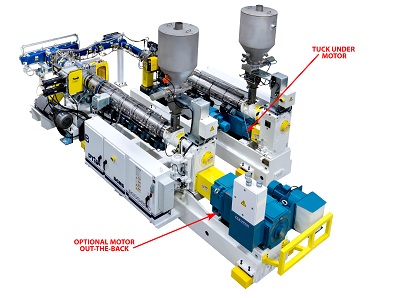

Processing Technologies International, LLC (PTi) has substantially reduced the footprint of its Super-G® HighSPEED Extruders, resulting in the highest extrusion output per square foot in the industry. The superior manufacturing output is made possible by the introduction of a tuck under motor which creates a smaller footprint for both Super-G HighSPEED models which are used for the processing of polypropylene (PP) and high-impact polystyrene (HIPS) for the packaging market. PTI is set to show off this high-output Super-G® HighSPEED Extruders at the upcoming NPE2018 May 7-11 at the Orlando County Convention Center in Orlando, Fla. (Booth #W6744).

Matt Banach, Senior Vice President of Sales and Marketing for PTi, said that the high-speed extruder technology sets a new industry standard in terms of output per unit area due to the tuck under option. The Super-G® technology has set the standard for high-density manufacturing, now delivering unprecedented output per square foot.

PTi’s Super-G® SGHS3000-36D model features a vertical U-configuration and tuck under motor which reduces the machine’s footprint by more than 33% to 12-ft 8-in, compared to 17-ft 7-in for the original model. The Super-G® SGHS3000-42D model is also offered with the tuck under option and offers a comparable footprint reduction and similar output gains.

The Super-G® HighSPEED tuck under option is commercially available and several machines have already been installed in the U.S.

In 2017, PTi entered the high-speed extruder segment with the launch of its Super-G® High-Speed Extruders which deliver significant performance advantages and overcome the limitations of competitive products. PTi’s high-speed solution delivers improved melt quality as a result of its Super-G® Lobe screw technology and is offered integrated with all of its advanced G-Series® Configurable roll stand configurations.

The Super-G® SGHS3000-36D is equipped with a 500 hp motor and runs at a maximum speed of 1000 rpm while the Super-G® SGHS3000-42D has a 600 hp motor and runs at a maximum speed of 1200 rpm. For processing of PP, the Super-G® SGHS3000-36D has a production output of approximately 3,000 lb/hr.

In addition to delivering excellent melt quality, PTi’s high-speed extruders feature carbide-lined barrels and Colmonoy hard-faced feed screws versus case-hardened screws as featured on competitive models.

The Super-G® high-speed extruders boast an oversized feed section which promotes higher regrind feed rates (up to +70%) along with a streamlined feed hopper with support, delivery chute, and tramp metal protection. Other key features include feed screw removal out-the-back of the unit, an easy-cleanout vent chamber, and linear bearing barrel glide support (patent pending). Special air-cooled heater and blower assemblies limit the exterior heater temperature for safety and efficiency purposes (< 110°F) versus competitive models which can be as high as 500° F.

Processing Technologies International, LLC (PTi)

Tel: +1-630 585 5800

Website: www.ptiextruders.com.

Booth: W6744