`The trend towards flexibility in machining processes with a high degree of automation is still clearly enduring in many sectors. Nonetheless, with all the innovative strength and performance power of such systems, we still have the question: When and how does it make sense to automate? And, is the robot a means to an end or the deciding factor?

Stefanie Flaeper, Managing Director at Transfluid, has the answers. The specialists for high-tech tube processing equipment have already been developing their t motion solution for process automation for many years and for a great variety of application areas.

"Of course, with all the enthusiasm for automation there is always the question of benefits. Because the reasons for deciding to go for an automated process, are certainly diverse. Sometimes the objective is to achieve process capability and quality independent of the operator. In other sectors or applications, the focus is on cost reduction for a process. Because a great deal of 'know-how' is required to be able to leverage the optimum results from the machining components through to operation", explains Stefanie Flaeper.

The question of suitable handling

Transfluid can rely on their wide product range for the realisation of the individually developed manufacturing cells. With the integration of well-proven technologies for tube bending or forming, the automation options are always consistently exploited. For example, if it is necessary to cut at the start, Transfluid's chipless orbital tube cutter provides a tidy route for direct further processing. As a result, it is possible to carry out forming processes at the end of the tube and bending pre-formed tubes, for example, without any delays.

With the great variety of possibilities, such as integrated labelling systems or optical measurement systems, the clarification of the general question of the layout of the respective handling system is one of the most important. "Robots are one variant, the other could be an electrical servo driven 4-axis linear handling unit, for example. Both systems have their appeal - certainly the linear system if the central factors are the handling times, short tubes or machining prior to the bending process", says Stefanie Flaeper. The advantages of the linear systems in comparison to robots lie in particular in the high speed and that they are simpler to program. "Linear systems increase the degree of utilisation of the integrated machines. In contrast, a robot is a great deal more flexible. At least when it comes to automated tube bending", explains Stefanie Flaeper.

The robot as a machine

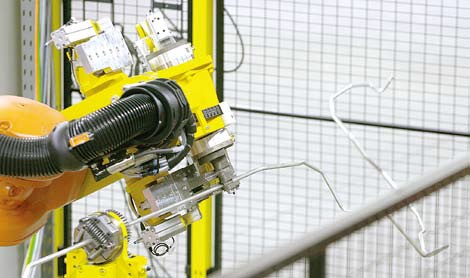

A supplementary concept for the forward-looking t-motion automation systems from Transfluid is the option to employ the robot as a machine rather than only for handling tasks. "With one of our current projects, we must find a solution and decide whether we install a bending machine and automate this via a robot, or simply take the opportunity to use a robot as a machine", says Stefanie Flaeper.

In order to realise this, the Transfluid engineers have simply put a bending machine into the robot's hand.

This robot bending machine is able to bend right-left with a single setting. And, it is extremely flexible, in particular when long tubes have to be bent – or for example, pipe-hose combinations whereby the hose has already been installed prior to the bending process.

No tool change and vibration-free automation

Because this enables the bending head to be equipped with several levels, it is possible to bend different tube diameters without a tool change. The advantage of such robot bending machines is obvious: The bending of long tubes can be automated without substantial vibrations and the bending speed can be maintained as relatively constant over the whole length. The robot has innate advantages when it comes to the handling of the tubes from a magazine and the transfer to a store after processing. This allows steel tubes up to 22 mm in diameter to be bent without a mandrel.

Robots also bend pre-machined tubes

In addition to conventional bending methods, there is also a further process available for using robots to bend tubes with an internal mandrel. This is fascinating if both ends of the workpiece have already been machined, for example. The robot can start with the bending from both sides. As a result, the Transfluid concept has opened up an amasing opportunity to bend both ends into the final shape without an additional length being required.

Programming was yesterday’s solution

"The programming of robots represents an entirely justified hurdle for many companies. For this reason we have made it simple and in fact missing altogether with our robot bending systems", stresses Stefanie Flaeper. With the Transfluid systems, the coordinates are loaded from the CAD system and the robot knows how it must bend. Furthermore, it is possible to connect to measurement systems and so manual corrections can be very simply implemented, as the robot is operated via a normal bending machine controller. As a result, the utilisation of the robot can be even more cost effective.

Plug & Play

With the intelligent networking of their processing technologies from chipless tube cutting through re-forming through to bending, and with integrated technical options, such as product marking, weld seam checking, camera checking systems or the feeding and fastening of external components such as flanges, Transfluid has been developing individually tailored automation systems for almost two decades. For specific challenges with linear handling for rapid cycle times or by robot for universal tasks and with complete incorporation of external systems or peripheral functions. This is how "Plug & Play" production starts.