In tool making in particular, metal blocks often need to be processed near to the final contour. In the steel trade, large numbers of remnant pieces accumulate, which can no longer be cost-effectively processed on conventional horizontal sawing machines. When sawing test pieces, the workpieces often need to be aligned diagonally or with the aid of fixtures. The LPS-T represents an interesting machine concept for these and many other applications.

The vertical arrangement of the bandsaw blade and the moveable material table means that material can be rapidly placed, aligned and clamped. The material support table features T-slots across its entire length, allowing even awkwardly-shaped workpieces to be securely held in position through flexible use of clamping devices during sawing.

An optional NC measuring device can also be used to speed up the set-up process even further. This is set up on the material table. The cutting depth can be conveniently pre-programmed in the touch control which comes as standard and the material can be aligned on the positioned measuring stop. The self-explanatory symbol-based menu system makes for faster familiarization of new operators and simplifies machine handling. The NC-controlled measuring device thus provides even greater flexibility and increased accuracy on a day-to-day basis.

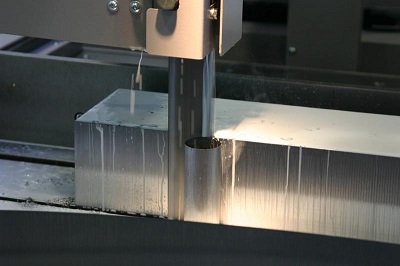

The robust LPS-T material table is precisely guided via four linear guides. The feed motion is generated via a ball screw and servomotor. A cutting pressure control system continuously monitors the cutting force in the tool and adjusts the cutting value in line with the actual conditions. The rapid response of the servo feeding system to the sensor system for the cutting pressure regulation thus systematically prevents overloading and premature wear of the bandsaw blades. The result: reduced cutting costs due to a longer bandsaw service life.

The LPS-T comes with a 4 kW saw drive and a highly stable saw frame as standard. Both bimetal and carbide bandsaw blades can be efficiently used. Almost all materials can be processed, from aluminium, tool and stainless steels, to nickel-based alloys. All blade-guidance parts are made from vibration-damping grey cast iron and reduce vibrations at the cutting point. Chips that adhere to the bandsaw blade are cleaned away by electrically-powered brushes on both sides of the blade which readjust themselves when the brushes are worn – a considerable advantage when it comes to maximising blade service life. And if, after many cuts, the bandsaw blade does need to be changed, this task can be completed in around two minutes by a single employee and without the aid of tools.

ADIDAS