Many in-depth tests have shown that air pollutants levels are higher in-vehicle than outside on the road. These fine airborne particulate matter and material emissions found inside the car can bring adverse health impacts, ranging from respiratory ailments to cardiovascular conditions.

Vehicle Interior Air Quality (VIAQ) studies have found that plastics and rubbers used in vehicle interior components release volatile organic compounds (VOCs) and semi-volatile organic compounds (SVOCs). That said, regulatory bodies are exerting more effort to develop harmonized methods of testing volatile substance emissions and evaluating indoor air quality in vehicles. This has required automakers to comply with differing guidelines and testing procedures frameworks for VIAQ adopted in several countries in Asia, the US and Europe.low odour and emission

New TPEs meeting standards in automotive applications

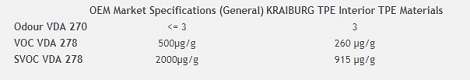

Thermoplastic elastomers (TPEs), as the widely used materials for automotive applications meet the low-odour requirement of the industry. KRAIBURG TPE offers a high performance TPE range, such as its recently launched FG/SF THERMOLAST® K series, which features low emission, low-odour and UV-resistance compounds that are easy to process.

Moreover, TPEs possess properties such as good weathering, oil, grease, and abrasion-resistance; fast, cost- effective processing; vibration-damping; and excellent adhesion markers. TPEs are used in vehicle interior applications such as control elements, anti-slip mats, window trims, cowl panels, spoilers, seals, air duct component, and many more.

KRAIBURG TPE in innovating materials that satisfy market criteria on VOCs and SVOCs, measures its success by customer satisfaction through a unique quality concept that takes people, processes and products into account, centred on exceptional, high quality and custom- engineered compounds.

KRAIBURG TPE is expected to reveal more innovative achievements and industry-breaking news in the coming months.