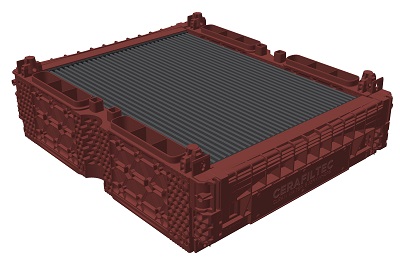

According to the United Nations, water shortages will affect two-thirds of the world's population by 2025 if current consumption patterns continue. CERAFILTEC, a manufacturer of innovative water filtration solutions, is helping to address this looming crisis with a unique filtration module molded from SABIC’s NORYL™ glass-reinforced polyphenylene ether (PPE) resin. The new module securely houses multiple high-performance silicon carbide (SiC) flat sheet membranes that can quickly and effectively filter demanding water sources, including seawater, freshwater, industrial wastewater and even hot water. NORYL™ resin can provide best-in-class hydrolytic and dimensional stability, chemical and high temperature resistance, and is certified for potable water applications under NSF/ANSI Standard 61. These critical properties enabled CERAFILTEC to replace previous modules requiring corrosion-prone steel framing with a fully injection molded design. .

“Prior to collaborating with SABIC and utilizing its innovative NORYL™ resin, we were repeatedly told that our vision of an all-plastic water filtration module was impossible,” said Kay Gunther Gabriel, CERAFILTEC’s chief executive officer. “But SABIC understood and shared our vision, and helped make this possible. During material validation, application development and mold trials, SABIC provided comprehensive documentation, data and technical support regarding its material to our team. Its assistance enabled us to inaugurate a new module production facility in Germany in less than a year. Today, CERAFILTEC is supplying a top-quality, durable and reliable product to customers and partners worldwide to help solve the clean water supply challenge.”

“We continue to invest in advanced materials and resources, such as our Water Management Center of Excellence, to collaborate with customers like CERAFILTEC, so they can develop next-generation applications that address urgent water challenges,” said William Wan, NORYL™ resins business director, Specialties, SABIC. “Our growing portfolio of materials for water management, such as NORYL™ resin, can help customers reduce costs and improve lifetime performance in demanding operating environments. SABIC aims to lead the industry in metal replacement solutions, as demonstrated by the plastic CERAFILTEC filtration module. Our specialized capabilities can help customers to create and manufacture solutions to meet global macro trends.”

Improving performance, lowering costs

Before learning about NORYL™ resin, CERAFILTEC designed filtration modules using less-robust plastics such as polyurethane, which tended to distort, deform and swell under exposure to water and weight. These materials required high-grade steel framing to stabilize the plastic and to prevent the ceramic membranes from cracking and causing leakage. However, steel is susceptible to corrosion, raises costs and restricts design freedom. Therefore, CERAFILTEC sought a material solution that could eliminate the need for the steel framing. The company also wanted this material to be as robust as the ceramic flat sheet membranes to align their anticipated lifespans.

According to CERAFILTEC, the use of NORYL™ resin enabled them to achieve:

> Seven-fold reduction in cost compared to the plastic and steel frame design, thanks to the efficiencies of high-volume, high-speed injection molding

> Extended life of the CERAFILTEC module up to 20 years, which is twice the lifetime of the plastic and steel frame design and matches the lifespan of the ceramic membranes

> Ease of assembly and operation because all process functions are integrated in the module. This factor helps to drive market adoption.

>Temperature extension for hot water applications, enabling the module to work in a broader range of conditions

> Material compliance with potable water regulations to accelerate approvals

> Corrosion resistance specifically used in seawater applications

> Optimizing Usability with a Modular Design

CERAFILTEC’s modular approach, and the strength and stability of NORYL™ resin, can allow the units to be stacked into towers and assembled in a wide variety of configurations. The configuration depends upon the volume of water to be filtered, space constraints and other factors.

Although the part design is standardized, CERAFILTEC took advantage of an extended temperature version of the NORYL™ resin to offer a hot-water (red-colored) module as well as a cold-water (blue-colored) version.

CERAFILTEC has already supplied the new filtration modules for water projects worldwide. They include a sewage treatment facility in Taiwan, a groundwater filtration operation in Jordan and wastewater filtration at a food manufacturing plant in Dubai. Future plans include expanding the use of NORYL™ resin to include small auxiliary parts (clamp, outlet, pipes) that are currently molded from a different material. A 100-percent NORYL™ resin module can help further simplify manufacturing and the company’s supply chain.

Jordan Extra Fly