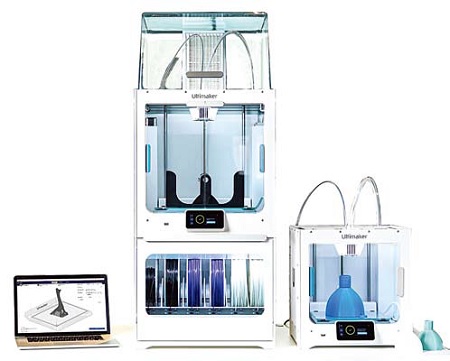

3D printers, software and materials that work together seamlessly. (source: Ultimaker)

Ultimaker, the global leader in desktop 3D printing, provides business enterprises with the support necessary when and where they’re needed.

To give an insight on how 3D printing can support businesses where traveling to tradeshows and one-on-one interactions are difficult, International Metalworking News for Asia connected with Mr Benjamin Tan, Vice President of Ultimaker Asia Pacific. He disclosed how the company is responding to COVID-19, and details the evolving future of manufacturing, engineering and design paradigm.

Value chain disruptions

Benjamin Tan, Vice President, Ultimaker Asia Pacific

“Covid-19 has disrupted industries around the world. As a result, global supply chains have also taken a major hit. Fortunately, many of our customers have seen minimal disruptions to their value chains, thanks to the distribution model enabled by 3D printing,” Benjamin said.

He explained that instead of manufacturing an item and shipping it to a warehouse in another country, 3D printing allows for digital files to be produced on-site. This has empowered our clients to circumvent the problems of border lockdowns globally, enabling their supply chains to remain open and fluid.

On a day-to-day basis, Benjamin and his team engage companies to identify challenges and areas of improvements, through multiple meetings and physical site scans. An important aspect of the buying process as it enables them to equip customers with industrial 3D printing knowledge. With face-to-face interactions no longer possible, they have been conducting virtual site scans to support their clients.

“As part of our channel and distribution model, a large part of our sales activities were driven through participations in tradeshows and workshops. Now that these avenues have been cancelled, we have turned to webinars, e-conferences and e-trainings with partners and customers alike to ensure business continuity,” he mentioned.

Affected industries and business strategies

During these period, Benjamin noted that many plants and factories are either on partial or full lockdowns. “As a sales organisation, it has certainly impacted the way we interact with our customers. Internally, we are taking the time to re-calibrate our efforts through more realistic forecasts and alignment of strategies, he remarked.

Externally, all hands are on deck to engage customers through webinars and e-conferences, he rationalised. “We are also equipping our partners with frequent, more intensive training on 3D printing so that they can better support customers with troubleshooting. This multi-prong approach helps us stand ready to seize opportunities when the pandemic is over,” added Benjamin.

Making realistic changes

According to Benjamin, many of the conversations that took place pre-COVID may no longer stand. Customers may face greater budget constraints and decision making may take longer.

“We will have to look out for changes in customers’ behaviours and sentiments, and respond accordingly. There may be a need to re-evaluate policies and agreements to work around the issues. We anticipate that there will be operational impacts. With a reduction in global demand, factories will not be producing at the same volume as they used to. This means a direct hit at the supply side. All these macro changes will require deeper discussions with our customers, so we can see how to better support them and cater to their needs,” he detailed.

Benjamin commented, “We can’t control what’s happening around the world, but we can control how we react to the crisis. As leaders, our employees turn to us to guide them through the crisis. From a business point of view, it may no longer be business as usual. Companies will be forced to digitise or change their business model. At Ultimaker, we have always been a digital-first company. Hence, from a technological standpoint, there would not be a drastic shift or transition.”

Strategically, the fundamentals will not change, he added. “However, the way we engage our customers has to change. We now have to adjust to a virtual mindset, encouraging virtual visits and workshops. We are still focused on giving our customers the support they require, physically or virtually. Team members will need to take on a more nimble approach towards remote working, empowered by tools such as Zoom, Microsoft Teams and Google Hangouts. This will be the new norm of working post-COVID,” he declared.

Repositioning for stability and growth

Benjamin believes that companies will be responding to competitive pressures, looking to reduce overheads and improving profit margins. He is positive that 3D printing technology which is an essential part of progressive business solutions and processes, is poised to transform the way companies do business.

“There are immense opportunities for 3D printing to be successfully harnessed in multiple use cases in key industries. Many manufacturers have already embarked on their digital journey, utilising 3D printing as an essential part of their automated workflow, boost their supply chains, or simply to help humans work smarter and more efficiently,” Benjamin expressed.

He conveyed, “We will continue to support our customers through the identification of areas of improvement and help them discover new applications to enhance their workflows and processes. With the right 3D printing infrastructure in place, companies can remain commercially viable through increased productivity and greater savings, as well as faster time to market. “

Do more with Ultimaker S3

Conclusion

Benjamin set out to enunciate that every crisis brings about opportunities and this is no different. “The pandemic has exposed vulnerabilities in global supply chains. With manufacturing environment becoming more volatile, businesses will be looking to simplify their supply chains. 3D printing has proven that it can plug the gap in a centralised manufacturing model and augments the need for digital manufacturing,” he stated.

Finally, he highlighted the imperative need for companies to transform or shape their business model to accommodate greater use of 3D printing, enabling sustainable growth.

Benjamin places a lot of value on the practical applications of 3D printing, specifically how this can help businesses in Asia Pacific region. He works closely with its network of sales partners to determine the best applications of Ultimaker’s solutions.