VEOLIA Water Solutions & Technologies (Thailand) Ltd has supplied Associated British Foods (Thailand) Ltd with full turnkey wastewater treatment plant.

The newly installed treatment plant integrates several innovative technologies including Dissolved Air Flotation (DAF), Biothane® Upflow Anaerobic Sludge Blanket (UASB), AnoxKaldnes™ Biological Activated Sludge™ (BAS), and Hydrotech™ Drumfilter , within ABF’s Ovaltine manufacturing plant in Samutprakarn, Bangkok. With this end-to-end wastewater package, ABF, a multinational food manufacturer, will be able to handle its wastewater treatment needs on premise, catering to both existing and future flow requirements projected for the next decade.

“Working with ABF shows how we can effectively provide a full range of wastewater solutions from start to end. Our experience in the food and beverage industry has equipped us with the know-how to mitigate the client’s concerns, and we are confident of meeting their project expectations,” says Michael Poonpipat, Business Development Director, Projects, Thailand, Veolia Water Technologies.

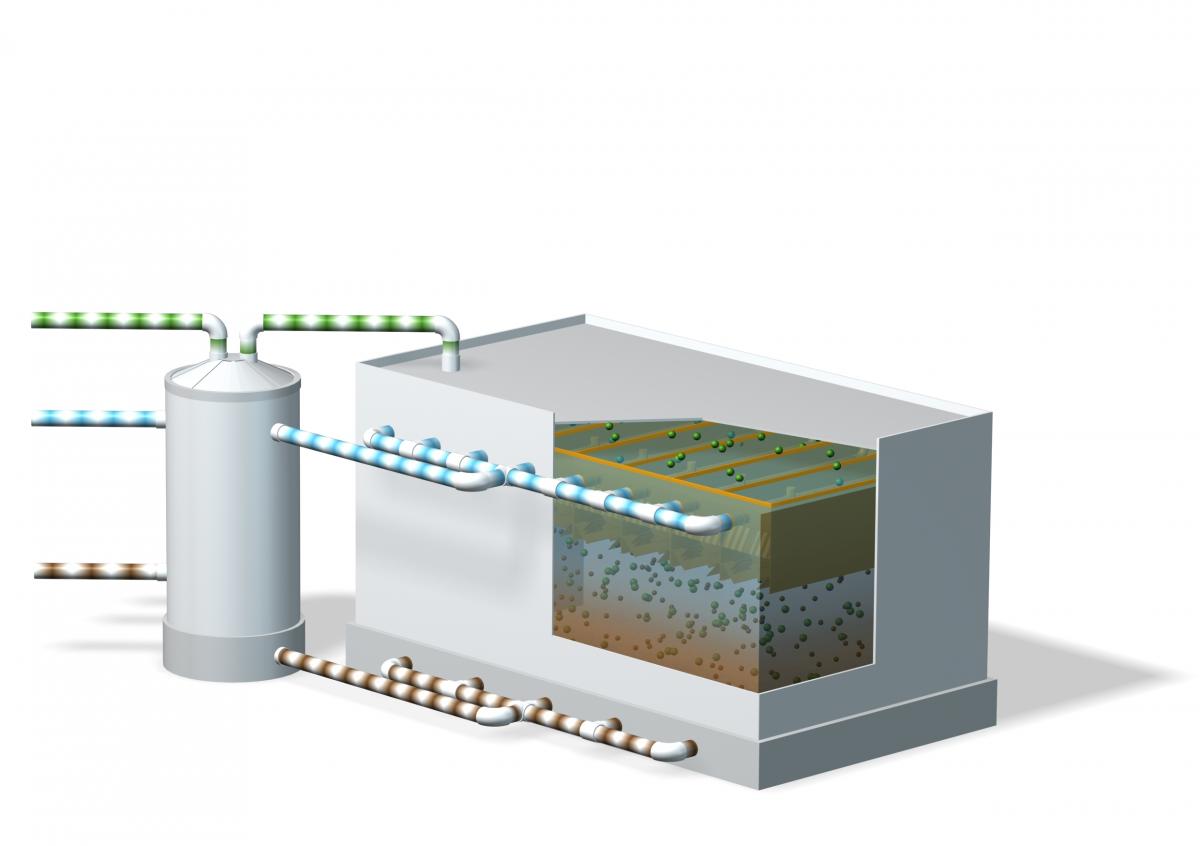

Biobed Advanced UASB

Design fits into limited space

Faced with the challenge of designing a wastewater treatment plant located within the client’s space constrained manufacturing grounds, Veolia recommended key technologies that could effectively treat their wastewater volumes and COD loads. Mr Poonpipat shared, “We had to be creative in designing a compact yet robust wastewater treatment plant that could handle a high flow rate within a limited space. One of the most attractive features of Veolia’s water and wastewater solutions is its compact design, which takes into account space constraints that clients face without compromising on performance.”

The Dissolved Air Flotation (DAF) unit pretreats the raw wastewater, removing fat, oil, and grease (FOG) before the Biothane® UASB anaerobic treatment process. The UASB anaerobic system then converts COD present in the conditioned wastewater into biogas. Veolia’s AnoxKaldnes™ BAS™, a combination of Moving Bed Biofilm Reactor (MBBR) technology with conventional activated sludge (AS), is next applied to promote a stable and more efficient activated sludge process with improved sludge settling characteristics. The effluent then enters a second DAF clarifier unit for biological sludge separation, before the Hydrotech™ Drumfilter system separates the remaining particles from the wastewater.

Michel Otten, Technical Director, Asia Industrial, Veolia Water Technologies, said, “This project with ABF carries great significance for Veolia as it showcases our ability across disciplines, from conducting preliminary market studies, to recommending targeted engineered solutions, and finally to constructing the wastewater treatment plant. It reaffirms Veolia’s leading position as a professional water and wastewater solutions supplier, and also as a trusted design-and-build partner for manufacturers across different markets. Veolia looks forward to working closely with ABF to ensure flawless project execution for a successful handover in June 2016.”

ABF can obtain biogas in the process of treating the wastewater. This serves as alternative energy for heating the company’s boiler systems.

Adidas Fotballsko