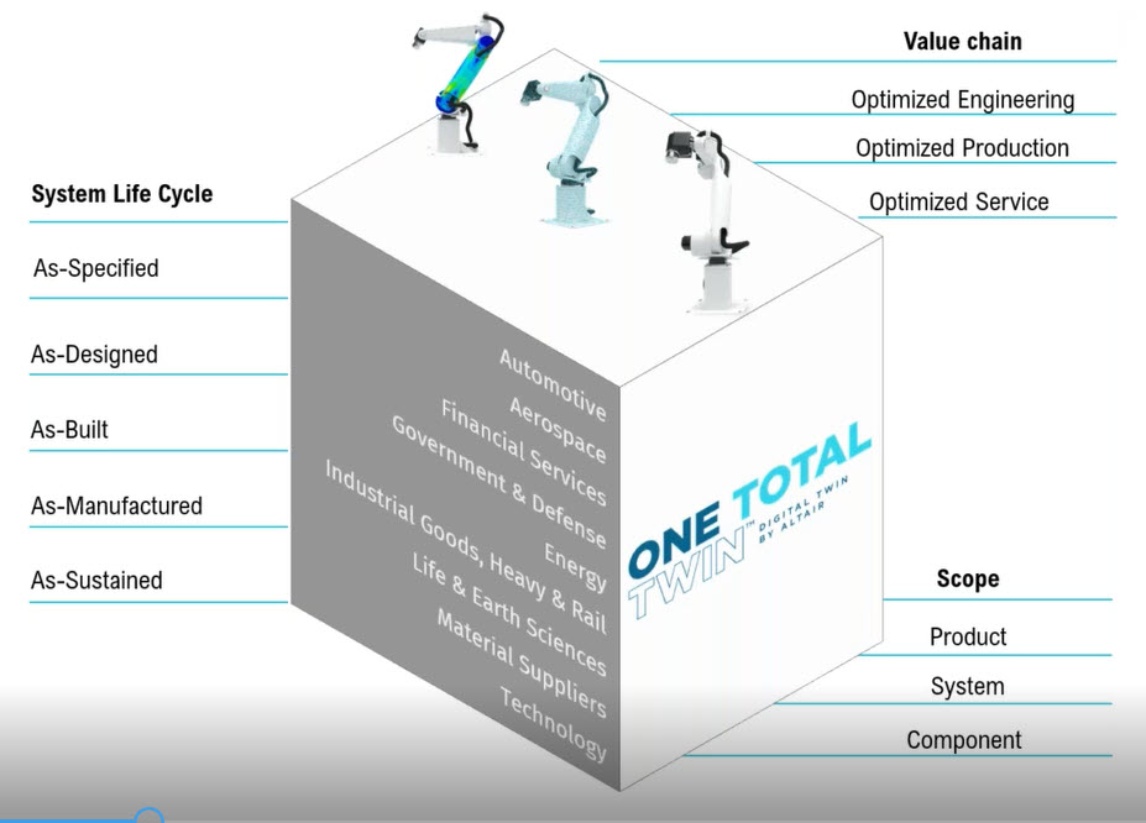

Altair, a global leader in computational science and artificial intelligence (AI), has announced the launch of a comprehensive technology solution for digital twins. This is designed to provide highly interconnected, cross-discipline capabilities that can be deployed at various stages of the product lifecycle. "Altair offers the first commercially available digital twin solution that can transform the way people and organizations design, develop, implement and improve products and processes," said Sam Mahalingam, chief technology officer, Altair. "Going forward, we will continue to solidify our leadership position in digital twins to further drive democratization and provide more accessible digital twin solutions."

Combining Altair's expertise in simulation, high-performance computing, AI, data analytics and the Internet of Things, the company said it will enable companies to use Digital Twin technology at every stage of the product lifecycle in the future - from concept to commissioning. The Digital Twin is part of a cross-functional, enterprise-wide approach that promotes collaboration and eliminates departmental silos, Altair said. In addition, Altair's open, multi-vendor Digital Twin solution represents the first offering that gives customers the flexibility to run Altair software anywhere - on-premise, in the cloud, hybrid or via plug-and-play appliances. In addition, users are said to have the freedom to choose Altair units from a comprehensive toolset thanks to the cost-effective, value-based licensing model.

As-specified twin tools are used in the pre-production phase, covering system requirements, development, validation, performance prediction, optimized mechatronic product development and more. In this way, systems and solutions can be designed, analyzed, and optimized without expensive physical prototypes. In addition, multiphysics simulations can be merged with state-of-the-art HPC, AI, and data analysis capabilities in a unified environment. As-specified tools include Altair Activate, Inspire, Drive, HyperWorks, PollEx, Flux, Compose, Feko, PSIM and XLDyn (through Altair Partner Alliance).

Altair distinguishes between as-built and as-manufactured twins for the production phase. As-Built twins enable extended virtual system dynamics to be evaluated in what-if scenarios, reduced-order models (ROM) to be created, design sensitivities to be identified, and faults that have occurred to be resolved. As-Manufactured Twins, on the other hand, help assess integrated software, processors and hardware associated with systems such as driver interactions, ergonomics, immersion, virtual reality and more. Both twins help companies simulate realistic and unexpected events, improve functionality and operations, and realistically represent innovations in interactive and realistic environments. The corresponding twin tools are Altair Embed, MotionSolve, HyperStudy, Panopticon, Design Explorer and Vortex Studio (through the Altair Partner Alliance).

That's not all. Finally, for predictive analytics and predictive maintenance, Altair offers tools for as-sustained twins. Analysis of real-time data streams and machine learning are designed to help determine the remaining useful life of a system, gain insights based on anomaly detection, improve system performance or create optimized maintenance routines, among other things. The as-sustained twin tools provided by Altair are called Altair RapidMiner, SmartWorks, SLC, Monarch and Knowledge Studio.

Last but not least, users can also call on Altair's Digital Twin Consulting team to accelerate the adoption of digital twins in a variety of industries, including aerospace, telecommunications, banking, financial services, manufacturing, energy and electronics. For example, Altair's solutions enable companies to predict and optimize battery performance in buses, analyze and optimize the performance of an airborne radar system, improve wind turbine efficiency, analyze credit risk, monitor and detect financial fraud, perform prescriptive performance optimization, predictive maintenance of consumer products, and - among many other things - even develop an ideal coffee machine.