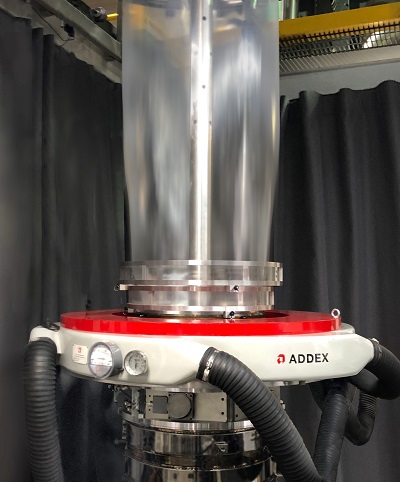

Addex Inc. will launch the latest iteration of its patented Intensive CoolingTM technology, the “Short Stack,” at the upcoming K 2022 exhibition (Hall 17/C41), which runs Oct. 19-26, in Düsseldorf, Germany.

Short Stack is a major upgrade to Addex’s Intensive Cooling system which was first introduced at K 2016. It typically delivers a 25% increase in output over the company’s original Intensive Cooling “Down-on-the-Die” version, which already improves output by 10-15% over conventional dual-flow air rings. Addex has taken its Intensive Cooling technology to the next level, affording processors even greater output and productivity, according to Bob Cree, President of Addex Inc. Mr. Cree adds that Intensive Cooling products will continue to evolve, fueled by ever more demanding customer processing requirements.

Intensive Cooling is Addex’s unique approach to cooling the bubble which changes the common aerodynamics of present-day blown film air rings to dramatically increase stability and output. Addex has successfully added additional high-velocity air streams to the traditional single, high-velocity “main lip” air stream common to all air rings. Each new high-velocity air stream naturally provides a firm stabilization “lock point” that not only provides intense cooling, but also firmly holds the bubble in place, providing what some processors call “incredible bubble stability.” Another unique design element is sealing the air ring to the top surface of the die. Positive stabilization and high-intensity cooling can begin earlier in the process, literally just above the die lip, which makes hard-to-run films capable of running at higher output speeds.

In the new Short Stack configuration, the bubble is pulled through a circular enclosure located between the die and air ring that naturally pulls the bubble into an oversized air ring which further increases output. Unlike other raised-up systems that are difficult to start up because the bubble must be pulled out and around equally oversized internal bubble cooling (IBC) hardware (which is required to push the bubble outward into the air ring), the Short Stack does this naturally, so it can be run with or without conventional IBC hardware.

The Short Stack incorporates an additional Intensive Cooling element that adds two more high-velocity air flows to the original Down-on-the-Die version released in 2017 (which had one additional lock point), for a total of three locking points, guaranteeing substantially higher output rates due to the increased stability, which in turn allows for processing much lower melt strength materials than possible before. Another major advantage is that few, if any adjustments are needed, even with material changes, making it easy to run.

The Addex Short Stack is proving to be successful over a wide range of processes including larger blow-up ratios/thin materials; smaller blow-up ratios/thick materials; along with high-melt strength as well as very low-melt strength processes. The company guarantees an output increase of 20-30% for retrofits. Since Short Stack is not height-adjustable and adds three more points of stabilization, it doesn’t require a highly trained operator to run it, unlike other height-adjustable raised-up systems.