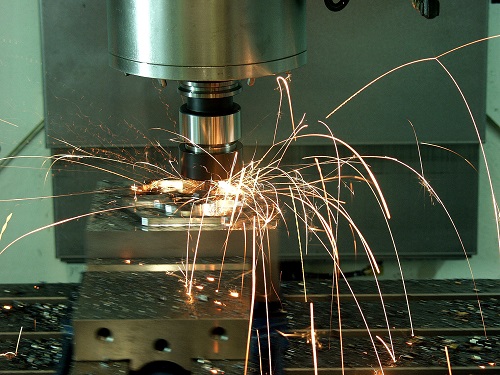

At first blush, it might appear that the actual spindle doesn't do much on a vertical machining centre. Yet, the tool cuts the metal, the table moves, the motion control system controls the precision and movement, and the software does the rest. The spindle is nothing more than a motor that lets a tool be attached to it and takes commands from a servo.

At first blush, it might appear that the actual spindle doesn't do much on a vertical machining centre. Yet, the tool cuts the metal, the table moves, the motion control system controls the precision and movement, and the software does the rest. The spindle is nothing more than a motor that lets a tool be attached to it and takes commands from a servo.

The above depiction may be true. The spindle may not be overly complex or smart or beautiful, but it sure does work hard and endures a lot of abuse. The amount of force and wear and tear it must endure means the design of the spindle and the quality of the parts buried within the spindle are vital to your spindle's performance and its lifespan. The spindle is truly the heart of the machining centre.

When you start to research spindle technology, you find the bearing system is often at the centre of the discussion. It can get mind-boggling, especially with the acronyms flowing freely—dN value benchmarks and formulas; O or DB mounting versus DF or X configuration; ABEC standards, and so on. An overview of key considerations when researching a CNC machining centre's bearing system covers the highlights—material, type, arrangement and lubrication.

Bearing system of the spindle

In a bearing system, the balls roll between the inner and outer steel raceways. The material used for the ball bearings affects temperature, vibration levels and the life of the spindle. Hybrid ceramic bearings offer distinct advantages over typical steel ball bearings. Why?

Less mass

Ceramic ball bearings have 60 percent less mass than steel balls. This is significant because when a ball bearing is operating, particularly at high rotational speeds, centrifugal forces push the balls to the outer race and then begin to deform the shape of the ball. When the bearing starts to deform, it starts wearing faster and leads to deterioration. Ceramic balls with less mass will not be affected as much at the same speed. In fact, the use of ceramic balls allows up to 30 percent higher speed for a given ball bearing size without sacrificing bearing life, according to information from a manufacturer of high-speed milling spindles.1

Elimination of cold welding

Ceramic balls do not react with the steel raceways, eliminating a condition called cold welding—a major cause of bearing failure. Cold welding occurs when the microscopic cold welding of ball material to the raceway causes surface wear. The cold welds actually break as the bearings rotate and that creates surface roughness that leads to heat generation and bearing failure.

Operate at lower temperatures

Due to the nearly perfect roundness of ceramic balls, hybrid ceramic bearings operate at much lower temperatures than steel ball bearings, which results in longer life for the bearing lubricant.

Vibration levels are lower

Tests show that spindles utilising hybrid ceramic bearings exhibit higher rigidity and have higher natural frequencies, making them less sensitive to vibration, which results in longer life for the bearing lubricant.

Lubrication of bearings

Proper lubrication of bearings is essential. There are several systems that machine tool manufacturers use to keep the bearings properly lubricated—such as oil-mist, oil-air, oil-jet and pulsed oil-air. Such systems are sometimes necessary if bearing spindle speeds are in excess of 18,000. However, they add to maintenance costs and increase the replacement cost of the spindle. Additionally, these lubrication systems must be monitored to make sure the ratio and the amount of oil and air and/ or mist are correct.

Permanently lubricated bearings are the best option for keeping maintenance costs down and replacement costs lower. With permanently lubricated bearings, you do not have to hassle with the use of lubrication. It's handled during the assembly of the spindle. The bearings can also be pre-packed with grease (permanent lubrication) by the bearing suppliers.

Various spindle technology

Spindle technology offers various ways to drive the spindle—belt, gear, inline and built-in motor. With a belt-driven spindle, make sure the belt is easy to maintain and easily accessible to minimise maintenance costs. Additionally, the type of belt will affect the noise level of the machine. A belt with a herringbone design is quieter than other belt designs because of the way it disperses trapped air to reduce the noise.

Gear-driven spindles add to the cost of the machine and can be noisier and require more maintenance than their competitor—the belt-driven spindle. There was a time when a gear-driven spindle may have been preferred over a belt-driven spindle, but the advances in materials and belt design have proven it to be a low maintenance alternative.

The inline spindle (sometimes called a direct-drive spindle) is designed so the spindle is coupled directly to the motor. Inline spindles provide excellent surface finish, smoother and quieter operation. Another type of spindle is the built-in motorised spindle that literally has the motor built into the spindle. These spindles are generally used when higher spindle speeds (in excess of 16,000) are required. These spindles are more costly compared to belt spindles.

No matter the type of spindle, the motor that drives the spindle is obviously important. Motors with two sets of windings—called dual wound spindle motors—provide more cutting torque and material removal. Single wound motors are used where lower torque is sufficient and higher base speeds are not an issue.

Enemies of the spindle

Enemies of the spindle

The two major enemies of the spindle are, heat and contaminants (namely, chips and coolant invading the bearing system). Firstly, find out what design features are included (or available as options) that protect the spindle. Historically, the most common cause of spindle failure has been bearing failure due to contamination from coolant ingress, condensation, contamination or chip damage. You want the spindle temperature to stay cool and you want to make sure contaminants stay out.

In most cases, contaminants enter the spindle because the spindle seal failed. Next, find out what design measures the machine tool manufacturer has taken to keep the seal tight. An air purge system uses a labyrinth seal and purges the seal with positive air pressure to keep contaminants out. A dual air purge system, a system with two ports (usually upper and lower) is one design feature that works well to keep contaminants out of the way.

Temperature is the other factor that leads to spindle problems. Because heat causes steel to expand, manufacturers should explain what measures they have taken to protect the spindle from head growth— which leads to mostly Y and Z axis changes. Heat exchangers or chillers (most common) are used to keep the spindle cool and control spindle growth as well as head growth. This type of system adds life to the spindle and reduces head growth, and is typically used when you're running long cycles or high duty cycles. The selection of the chiller is dependent upon the application. For extended high-speed applications, you may want to investigate a thermal stabilisation system. This system uses a thermostat with an oil chiller to automatically cool the spindle as needed.

Tooling considerations

Another contributing factor to spindle performance is the tooling used. Using unbalanced tools, worn tools and/or tools that are too long can affect the longevity of your spindle. Like the spindle, temperature can have a negative impact on tooling. Find out if the spindle comes with a coolant ring or uses flexible coolant nozzles. With a coolant ring, you want to find out how many nozzles there are and whether they are adjustable. Obviously, the more nozzles the better and having the ability to adjust the direction of the nozzles is an advantage to cover a large range of tool lengths without frequent adjustments.

Coolant Through the Spindle (CTS) is generally recommended when machining at 12,000 rpm or more, and you have custom tools or expensive tools that you want to ensure are protected. CTS also is recommended at lower rpms for certain applications and duty cycles. Prices vary for this feature depending upon the pressure of the CTS and how the spindle was designed.

Just like tires on a car, you will eventually need to replace the spindle on your vertical machining centre. In your zeal to make a purchasing decision for a brand new machining centre, make sure you look ahead to the day when the spindle will need to be replaced. You need to know how much it will cost, availability of your type of spindle and downtime to install.

_____________

1 The information on the ceramic hybrid bearings referenced is from William Popoli, President, IBAG North America.