Around 2,700 companies from around the world will meet in interpack (May 4-10, Dusseldorf) to present cutting-edge technologies and packaging trends from the entire value chain. As leading suppliers of processing and packaging equipment to the global food industry, Heat and Control is excited to return to the world’s biggest industry trade fair after six long years of forced absence during the pandemic.

Heat and Control’s Asia Sales Manager Ricky Ong says they’re ready to showcase their latest and most cutting-edge solutions for the food industry, and expects greater production efficiency, resource management and sustainability to be key talking points at this year’s show. The company will be on stand in Hall 14, Booth 14A56.

“Interpack represents packaging and process industry’s biggest international overview of the market and there’s no denying our industry is in a state of transformation,” says Ong.

“As global demand for packaged snacks and frozen foods continues to rise — processors are being challenged with the rising costs of energy, resources and raw materials.

“These issues have driven an evolution in food processing technology, and we can’t wait to share our latest developments."

New technology from industry favourite FastBack® will be on display at the show and the new solution from Heat and Control is set to transform the horizontal motion conveying market — all over again.

FastBack 4.0 conveyor

A new solution for the category, FastBack 4.0 is a circular to linear drive horizontal motion conveyor which will offer unprecedented performance to food processors. A key feature is its new drive mechanism — which uses rotational (circular) drive motion to produce a horizontal (linear) motion. The innovative design uses circular-to-linear drive efficiency — to convert rotational motion into pure horizontal motion — while also supporting the vertical weight of the pan.

FastBack’s patented circular motion can gently handle product — so it is undamaged and its coatings undisturbed — and achieves the industry’s highest travel rates, and flow rate capacity.

The new solution from equipment manufacturer Heat and Control is a culmination of more than 10 years development, multiple international patents, and a development partnership with industry-leading industrial bearing manufacturer SKF (AB SKF).

FastBack Lift and Tip

As consumer demand for new and different flavours continues to grow, snack processors are finding they must be ready to respond to consumer trends and create new products quickly. Heat and Control’s latest seasoning solutions will also be on display at Interpack, and the equipment will provide a revolution in flexibility for food processors wishing to season, salt, flavour, and coat all manner of products.

Development of the technology has innovated the seasoning process and can provide significant savings and flexibility for processors of potato chips, snack foods, crackers, tortilla chips, nuts and trail mix.

Heat and Control will showcase their innovative On-Machine Seasoning (OMS) system at Interpack. This system is proven to provide the industry’s most efficient and uniform coverage and can apply different seasonings — at each packaging station — without cross contamination.

On-Machine Seasoning (OMS) system

“OMS systems give processers the flexibility they need to create new products for seasonal campaigns or produce a wider range of products to respond to consumer demand,” says Ong.

“The best systems make it easy to manage product and seasoning flow, application rates and dwell time.

“Our patented On-Machine Seasoning (OMS) application method is proven to provide the industry’s most efficient and uniform coverage.”

In addition, OMS systems provide significant savings and flexibility to processors because they apply seasoning to products just before they enter the weigher.

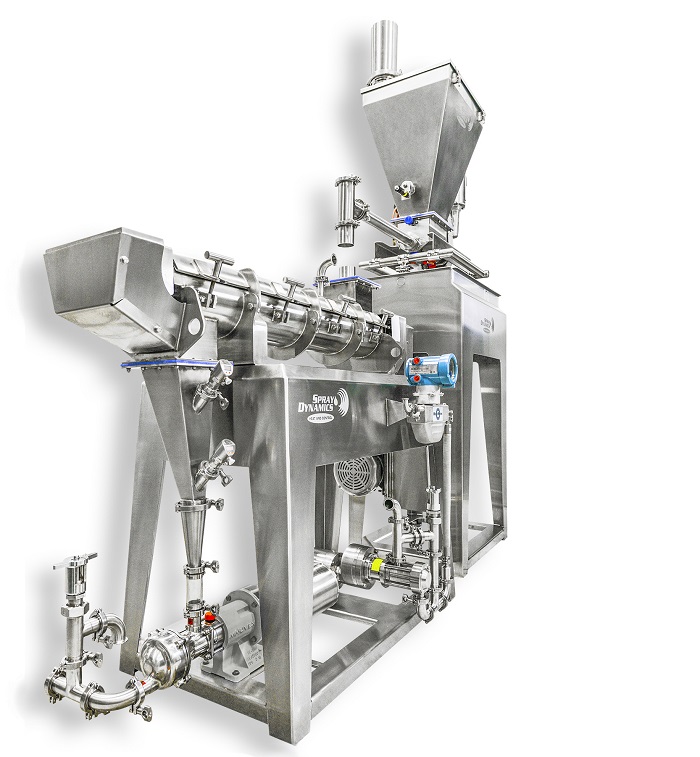

Spray Dynamics - Continuous Mixer with Dual Drive & Uni III

FastBack Revolution Seasoning System

Heat and Control will also display their FastBack® Revolution Seasoning System (RSS) at interpack. This on-machine seasoning system incorporates multiple innovations — in a complete system approach. It is able to produce consistent seasoning coverage with little seasoning waste — allowing processors to produce consistent product – every item, every time.

The RSS provides superior seasoning performance using a combination of a patented dynamic AccuFlavor™ Tumble Drum, the efficiency of the Modular Dust Collection System, and the advanced FastBack 260E-G3 into one compact, cost-efficient, standalone unit designed to overcome seasoning challenges at the weigher. Ideal applications for this system include potato chips, snack foods, crackers, torilla chips, nuts and trail mix.

What’s on display?

1. FastBack Lift and Tip — feeding into Ishida Multihead Head Weigher and Inspira Snack bagmaker

2. FastBack 4.0-100

3. OMS system

4. Spray Dynamics - Continuous Mixer with Dual Drive & Uni III

Live demonstrations will take place on the Heat and Control stand in Hall 14, Booth 14A56.