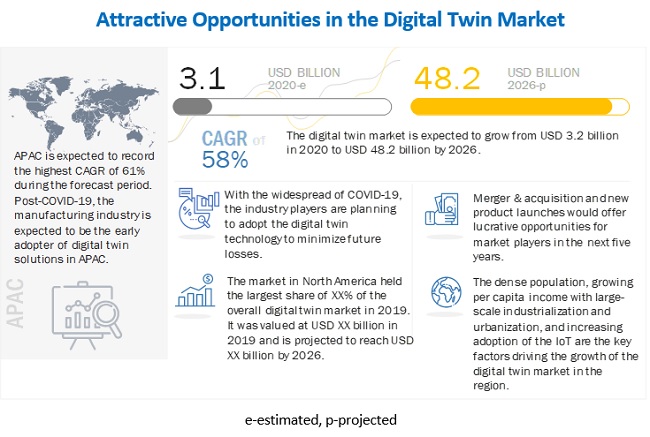

The global digital twin market size was valued at USD 3.1 billion in 2020 and is projected to reach USD 48.2 billion by 2026. It is expected to grow at a CAGR of 58% during the forecast period. Increasing demand for digital twins in the healthcare and pharmaceutical industries due to the outbreak of COVID-19 pandemic, the changing face of maintenance, and growing adoption of digital twin solutions to cope up with the COVID-19 pandemic are the key factors driving the growth of the digital twin market.

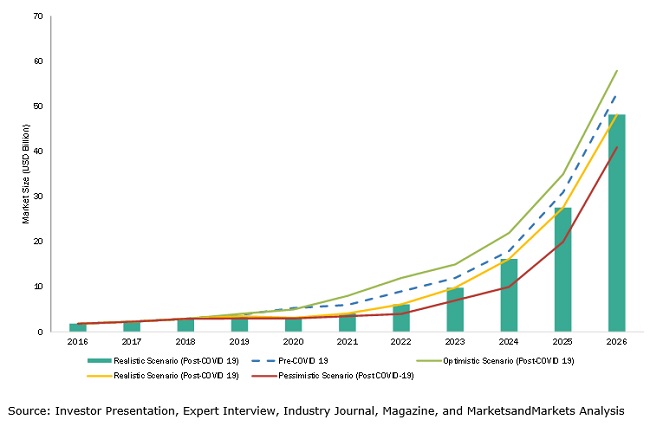

Pre- and Post-COVID-19 Scenario for digital twin market

The world is facing an economic crisis due to the sudden outbreak of the COVID-19 pandemic. The pandemic has affected the growth of the end-use industries. Major oil producers are running out of storage space for extracted oil, as the demand is on a declining trend. This has resulted in a massive gap between supply and demand. The energy & power, automotive & transportation, and aerospace & defense industries are also among the key end users of digital twin technology. These industries are also witnessing a declining demand due to the pandemic. There is a restriction on foreign trades due to the lockdown of international borders, non-operational distribution channels, and various government laws to take precautionary measures for public health and safety. However, the focus on the digitization of processes across the industries is expected to increase in the post-COVID-19 period. The increase in demand in the energy & power sector is also likely to boost the growth of the segment from 2021 to 2026.

Market Dynamics:

Driver: Increasing demand for digital twins in healthcare and pharmaceutical industries due to out break of COVID-19 pandemic

With the rapid spread of the novel coronavirus, the healthcare and pharmaceutical industries are at the forefront of combating COVID-19. Digital twin plays an important role in monitoring a patient’s health, the impact of tablets, and other parameters. Some of the industry players have grabbed the opportunity to fight against the coronavirus pandemic by providing different solutions. For instance, Exactcure (France), a French start-up developing a software solution to reduce medication errors, has developed a digital twin solution to lower the impact of inaccurately dosed medication. Through this digital twin solution, the efficacy and interactions of medications in the body of a patient based on their personal characteristics, such as age, gender, and kidney status, are monitored. Besides, the industry players are increasingly investing in research and development related to new daily life changes that have occurred due to the COVID-19 pandemic. For instance, the players are trying to develop a digital twin solution to identify people who have symptoms, are infected, or have recovered with antibodies and people who have come in contact with an infected person. By using such solutions, it will be easy for state or local governments to monitor green and red zones. Such solutions can be deployed in smart cities effectively.

Restraint: Data security due to use of IoT and cloud platforms

The implementation of digital technologies, such as the cloud, big data, IoT, and artificial intelligence, is increasing in various facets of businesses. Digital twin involves the integration of various IoT sensors and all the digital technologies for virtualizing the physical twin. With growing connectivity arises the risk of security, compliance & data protection, and regulations.

Increasing occurrences of viruses and cyber-attacks have raised concerns regarding data security. Important information can be stolen by malicious viruses in computer systems, resulting in a major loss to the companies. Failure of IoT infrastructure providers and cloud platform providers in implementing proper security measures might lead to disruptions in the flow of information. The industries that have implemented digital twins with such platforms are prone to malware attacks that are targeted at industrial systems due to the increasing dependence on Web-based data interchange and off-the-shelf IT solutions.

A large volume of data is more prone to the risk of security. The digital twin gathers information from many aspects of the business into one place. The data includes IPs, sensitive data as well as access to the physical assets, all of which are critical information. The vast influx of data is valuable to companies as well as hackers. Business planning needs to include data security, data integrity, privacy as well as compliance considerations. Therefore, it is essential to ensure that good security practices are already in place while deploying the digital twin, may it be for a product, process, or a complete system/unit.

With the rise in cyber-attacks on the critical infrastructure over the past decade, cybersecurity has become a major concern among users and vendors of industrial automation. Thus, the increasing threat pertaining to the security of the data, which is connected to the cloud, is expected to be a major restraint for the growth of the digital twin market.

Opportunity: Implementation of digital twins in the manufacturing industry to handle several issues due to the spread of COVID-19

Due to COVID-19, the industry players are facing many challenges related to health and safety, supply chain, supplier resilience, labor shortages, and others. To reopen a business, companies have to follow all the norms implemented by governments to curb the spread of COVID-19. In the current scenario, the industry manufacturers required is real-time visibility across corporate boundaries and down to the supply and demand chain. This can be done with the help of digital twin technology. The digital twin acts as a powerful digital shadow. They gather all the interrelating data sources from an asset’s entire lifecycle as its semantically defined, data-based virtualization.

A digital twin can be used to create twins of components, assemblies, people, or an entire manufacturing plant and can be combined in multiple ways to create a solution with numerous sources of data and information. Digital twins help to extend capabilities, increase flexibility, and mitigate the risk of business failure. For instance, Rolls-Royce has implemented the digital twin-based interoperable ecosystems to deliver the next generation in customer service.

Challenge: Lack of awareness regarding cost benefit of the adoption of digital twins

Companies do not have any specific plan for the implementation of digital twins for product management and have not made any significant investments yet. As the technology is new for many companies and requires significant changes, the companies are unclear about the economic benefits, investments involved, and the cost benefits in the near future. The determination of the potential of a digital twin is considered to be very complex and diverse, which further complicates the adoption of this technology.

System digital twin to account for a larger share of the digital twin market by 2026

The market for system digital twin accounted for the largest market share in the 2019. This growth can be attributed to the increasing use of digital twin for systems in various applications. For example, in the aerospace & defense sector, the LOCOMACHS has implemented a digital twin for the entire assembly line for an aircraft wing for performance monitoring. In addition, in the automotive & transportation industry, Tesla Motors is using a digital twin solution for every car it manufactures for better performance 33 and business improvement.

Automotive & Transportation accounted for the largest market share in 2019

Automotive & transportation industry accounted for the largest market share in the digital twin market in 2019. This growth can be attributed to the increasing usage of digital twins for designing, simulation, MRO (maintenance, repair, and overhaul), production, and after service. Automotive & transportation is one of the industries that will witness high growth in the post-COVID-19 period, as industry players will try to adopt digital solutions for their end-to-end operations to minimizes losses that have occurred due to the pandemic.

Predictive maintenance to account for the largest market share during the forecast period

The market for predictive maintenance application accounted for the largest share in 2019. The growth of the predictive maintenance application segment can be attributed to an increase in the use of digital twins for predictive maintenance in the post-COVID-19 period across various industries.

North America to hold the largest share in digital twin market during the forecast period

The North America holds the largest share in the digital twin market. In recent years, the development of various software and deployment of automation solutions in the manufacturing industries has improved production lines and downstream operations. These developments have positively impacted the growth of the market in North America due to the high economic growth and a large presence of vendors offering digital twins. Moreover, the increased R&D in the field of the IoT and IIoT and increasing demand for efficient and cost-effective technologies for product manufacturing are also supporting the regional market growth.

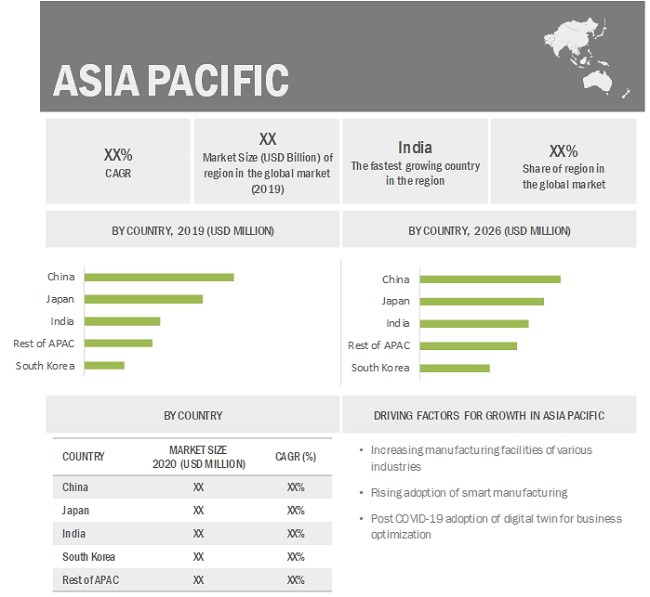

Digital Twin Market in APAC to witness higher CAGR during the forecast period

The market in APAC has been divided into India, China, Japan, and Rest of APAC. The market in APAC is expected to grow at the highest rate during the forecast period. China has a high potential for creating digital transformation in the manufacturing industries. The dense population, growing per capita income with large-scale industrialization and urbanization, and increasing adoption of IoT are the factors driving the growth of the digital twin market in the region. China’s rapid response to the pandemic allowed citizens to return to work (and normalcy) relatively faster as compared to other countries. One survey showed that almost half of the Chinese consumers expect the economy to rebound quickly and their routines to return to normal within the next 2 to 3 months. In APAC, other countries such as Japan, India, and South Korea are also affected severely, which has resulted in a significant downfall in the growth of the digital twin market in APAC. The market is expected to attain normalcy within a period of 1.5 to 2.5 years.

Key Market Players

General Electric (US), >IBM (US), >PTC (US), >Microsoft Corporation (US), >Siemens AG (Germany), ANSYS (US), SAP (Germany), Oracle (US), Robert Bosch (Germany), and SWIM.AI (US)., are among the major players in the digital twin market.

Recent Developments

In july 2020, Siemens launched the Simatic Real-time Locating Systems (RTLS) plus SieTrace software that offers real-time location information, which customers can use to control their manufacturing processes during the COVID-19 crisis and design their operating procedures accordingly. In the event of an employee contracting COVID-19, the solution will enable companies to quickly and efficiently control how employees interact with one another, with the production line and with the plant setup.

In june 2020, Bosch Building Technologies, a division of Bosch Group, developed an energy and cost-saving solution for its internal operations. The Energy Platform uses Microsoft Azure Digital Twin to monitor and analyze energy consumption in real time, helping manage business processes and provide actionable insights to operators.

In june 2020, Siemens has launched the Teamcenter X software, a new product lifecycle management (PLM) solution that will enable companies to quickly implement, scale, and integrate industry-leading PLM technology across functional disciplines. Moreover, access to Teamcenter X on the cloud will enable the creation of a complete digital twin, with multi-domain design and bill of materials integration.

In june 2020, Siemens acquired UltraSoC (UK), a provider of instrumentation and analytics solutions with exceptional capabilities in cybersecurity, to integrate UltraSoC’s technology into its Xcelerator product portfolio. The combination of Siemens and UltraSoC technology is expected to benefit the entire semiconductor product lifecycle, including structural, electrical, and functional capabilities of SoCs. It also supports Siemens's comprehensive digital twin with UltraSoC providing monitoring of the real device.

In june 2020, IBM and Siemens (Germany), a global technology provider with core activities in the fields of electrification, automation, and digitalization, have partnered to develop a new solution that will optimize the service lifecycle management (SLM) of assets by dynamically connecting real-world maintenance activities and asset performance back to design decisions and field modifications. This new solution combines elements of the Xcelerator portfolio from Siemens and IBM Maximo to improve product performance, maintenance, and operations.