Ascend Performance Materials has launched several several new specialty polyamides at K 2019 to meet the growing needs of its customers.

Among the new products that has attracted visitors' attention is Vydyne® XHT, long-chain polyamides and high-temperature polyamides. Vydyne® XHT, a new portfolio of heat-stabilized polyamide 66 and copolymers, is capable of withstanding prolonged exposure to temperatures up to 230 degrees centigrade. Using a combination of unique polymer chemistries and a multi-stage heat stabilization technology, XHT products push the boundaries of temperature resistance without sacrificing the processability, durability and mechanical properties PA66 is known for.

“Consistent high heat performance is critical in under-the-hood applications to accommodate for various load, torque and speed conditions in engines,” said Vikram Gopal, Ascend’s Senior Vice President of Technology. “We created Vydyne® XHT to perform across a broad operating window for our customers, who are today limited to products with narrow operating windows and poor performance outside those windows.”

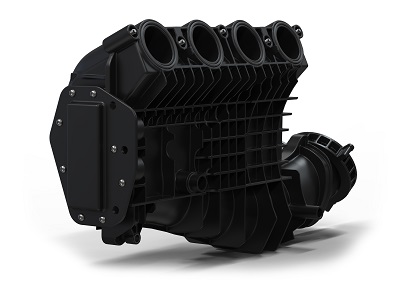

The Vydyne® XHT portfolio includes four glass-filled grades ideal for use in demanding automotive applications, such as charge air coolers, integrated air intake manifolds, exhaust gas recirculators and resonators. All XHT grades exhibit excellent flow and are regrindable, allowing excess material to be reprocessed, thus improving production efficiency.

Ascend also introduced a new portfolio of PA610 and PA612 long-chain polyamides. With low moisture absorption, high chemical and UV resistance, Ascend’s LCPA are engineered for a variety of applications, including monofilaments, battery seals, cable ties, automotive cooling and fuel connectors, and sporting goods.

“Our customers are driving innovation and meeting increasing demands across the industries they serve,” said Phil McDivitt, Ascend’s president and CEO. “In turn, we are building off our vertical integration and strong position in PA66 to bring the greater reliability, functionality and flexibility to make that innovation possible.”

The company is expanding into high-temperature polyamides. Ascend’s new HTPA grades offer higher strength, stiffness, chemical- and temperature-resistance for metal replacement and high-heat automotive applications.

Other products introduced include The new addition is the Vydyne ThermaPlus™, a heat-stabilised PA66 for cable ties and fasteners. Utilising Ascend’s proprietary multistage heat-stabilising technology, Vydyne ThermaPlus brings temperature resistance up to 230oC without sacrificing the processing efficiency manufacturers rely on. Vydyne ThermaPlus allows manufacturers to use their current PA66 processing equipment without an impact to efficiency to produce cable ties and fasteners for under-the-hood automotive applications.

Mr. Kevin Wu, Senior Vice President & Managing Director for Asia Pacific Region

Acteev is also a whole new nylon 66 textile resin that sets manufacturers and their customers free from the limitations of the past. With its odor-free, dyeable and non-silver technology, Acteev is the ideal answer for an active world that wants products that wear better, smell better, retain color better and are better for the environment."Our materials, such as Acteev, respond to the current market demands. Ascend can provide products for specific market requirements and this is our strength. Worldwide, Ascend has been monitoring the trends to develop products that conform to standards as well as market requirements," according to Kevin Wu, Senior Vice President and Managing Director for Asia Pacific Region at Ascend.

With Acteev, even the hardest-working apparel stays fresh. And Acteev passed ISO 20743 testing. The material can also be designed with any color, and without any need to mix in white. Yarn made with no-odor Acteev works just like regular yarn. "The material is also environmentally-friendly as zero silver goes into the water system," according to Mr. Wu.

Air Jordan