DP Technology, a leading developer of computer-aided manufacturing (CAM) software, announces a new update to their popular New ESPRIT series. The New ESPRIT 4.6 includes features such as turning toolpath enhancements, support for contour-type features in pocketing, and automatic tool orientation for 5-axis toolpath, improved support for multi-spindle and multichannel machines, and a new connection to the Machining Cloud tool catalog.

Version 4.6 includes a series of toolpath enhancements for turning cycles. These enhancements will reduce perishable tooling consumption, minimize intervention from the machine tool operator by creating more predictable machining processes, and reduce the need for manual NC code editing, further improving users’ efficiency.

The new support for contour-type features in pocketing allows users to use ESPRIT’s ProfitMilling cycle to rough out a profile without creating extra boundary geometry. Programming is easier, faster, and it enables automation with KnowledgeBase (KBM) integration. KBM is a centralized database that supports consistent institutional knowledge across an organization.

5-axis composite automatic tool orientation is a new programming method for the composite cycle. “This is a big leap forward for simplifying 5-axis programming and improving toolpath continuity,” says Yijun Fan, Director of Product Marketing at DP Technology. “It makes it much easier to program 5-axis composite, especially in parts with hard-to-reach areas.” Automatic orientation gives precedence to toolpath continuity, creating a better surface finish on a completed part.

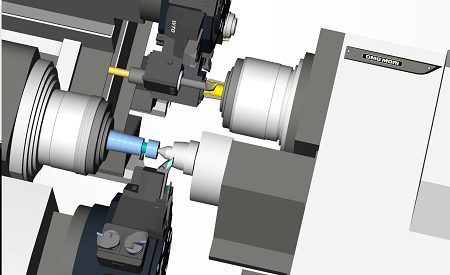

ESPRIT 4.6 enables support for multi-spindle machines with off-center sub-spindle with X-axis slide including machines with tailstock and sub-spindle mounted on the same X-axis slide.

Multichannel machines can be controlled with a new interactive method that synchronizes motions within a cycle. This new method enables advanced optimization for shaving seconds off the program of a high-volume production lathe.

Machining Cloud is the fastest way to find, select, and assemble tools from leading tool manufacturers. ESPRIT improves the connection to Machining Cloud with a simplified workflow and with the introduction of a new job manager for full control over the import of the tool assemblies.

DP Technology regularly releases product updates that often directly address customer feedback and requests. “Our product should match the way machining professionals work, not the other way around,” says Tania Campanelli, Director of Research and Development for DP Technology. “ESPRIT allows users to enjoy the benefits of the latest in manufacturing technology on their existing machine tools.”