为满足不同设计、处理及终端使用需求,日趋严格的卫生保健行业对多样化弹性体的需求更为迫切。美国Teknor Apex公司生产的高纯度热塑性弹性体具&

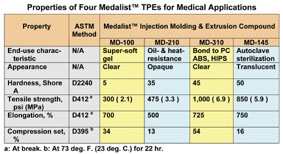

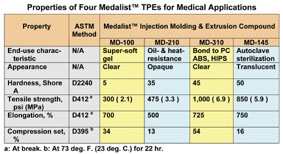

The stringent requirements of today's healthcare industry demand a diverse range of elastomers to meet the different design, processing and end use needs. Teknor Apex launched its innovative and far-ranging medical-elastomers program, MedalistTM, to provide device manufacturers with a wealth of new high-purity thermoplastic elastomer compounds along with a comprehensive body of tools and information for designers and processors. The Medalist initiative is a leap forward in our capability for serving medical manufacturers, said Andy Claytor, sales director. "While Teknor Apex has long supplied medical-grade compounds, the comprehensiveness of the Medalist range and the technical resources that accompany it will enable customers to use our program as a single source of elastomers for an array of applications and to eliminate guesswork in making material selections." The initial range of 33 Medalist compounds is already extensive. Shore A hardness spans an unusually broad range, from 5 to 87. Clear, translucent, and opaque formulations are available. The compounds fall into three series: Versatile Series (MD-100), whose widely differing grades meet many requirements encountered in medical manufacturing; Resilient Series (MD-200), formulated for enhanced toughness, oil-resistance, or heat-resistance; and Bondable Series (MD-300), for over-molding onto a variety of thermoplastic substrates. The three series are available worldwide. The accompanying table lists properties of four of the new Medalist compounds.

Will 33 Medalist compounds have been tested for compliance with ISO 10993-5 cytotoxicity standards and are free of animal-derived materials, vinyl, phthalates, latex, and additives not directly required for medical applications, said Lisa Charno, medical market manager. The sheer breadth of Medalist product offerings is remarkable ?from super-soft gels to elastomers that are semi-rigid like hard rubber. Grades are available for every major process in medical manufacturing, from injection molding to blow molding to extrusion of thin film. To aid designers in selecting the best compound for an application, and processors in optimizing production, Teknor Apex has prepared an expandable handbook and grade selector with complete information on every Medalist compound, including data on toxicology, sterilization, chemical resistance, and other properties, along with design considerations and processing guidelines. These are available at Teknor Apex's website dedicated to the product at www.medalistmd.com where data on all Medalist grades are presented. "The Medalist program is unique because it addresses such a wide range of performance requirements, subjects every one of the available grades to the same comprehensive testing, and addresses as many as possible of the issues that affect users of medical elastomers, including pending regulations," said Charno. "The whole point of the Medalist initiative is to provide梪p front梐ll of the information designers need to make the best raw material choice."

32 initial compounds for many medical requirements All Medalist elastomers meet ISO-10993-5 standards for non-toxicity and are compliant with U.S. Food & Drug Administration (FDA), RoHS, U.S. Conference of Northeastern Governors (CONEG), and California Proposition 65 requirements relevant to medical applications. They provide the advantages of thermoplastics ?outstanding processability, recyclability, colorability, and design freedom ?with the elasticity and tensile strength of conventional rubber.

The 17 grades in the Medalist Versatile Series (MD-100) series are all clear or translucent and include a 5 Shore A ultra-soft clear gel; tubing grades optimized for softness, kink-resistance, alcohol resistance, or high clarity; high-flow injection

SNEAKERS The stringent requirements of today's healthcare industry demand a diverse range of elastomers to meet the different design, processing and end use needs. Teknor Apex launched its innovative and far-ranging medical-elastomers program, MedalistTM, to provide device manufacturers with a wealth of new high-purity thermoplastic elastomer compounds along with a comprehensive body of tools and information for designers and processors. The Medalist initiative is a leap forward in our capability for serving medical manufacturers, said Andy Claytor, sales director. "While Teknor Apex has long supplied medical-grade compounds, the comprehensiveness of the Medalist range and the technical resources that accompany it will enable customers to use our program as a single source of elastomers for an array of applications and to eliminate guesswork in making material selections." The initial range of 33 Medalist compounds is already extensive. Shore A hardness spans an unusually broad range, from 5 to 87. Clear, translucent, and opaque formulations are available. The compounds fall into three series: Versatile Series (MD-100), whose widely differing grades meet many requirements encountered in medical manufacturing; Resilient Series (MD-200), formulated for enhanced toughness, oil-resistance, or heat-resistance; and Bondable Series (MD-300), for over-molding onto a variety of thermoplastic substrates. The three series are available worldwide. The accompanying table lists properties of four of the new Medalist compounds.

The stringent requirements of today's healthcare industry demand a diverse range of elastomers to meet the different design, processing and end use needs. Teknor Apex launched its innovative and far-ranging medical-elastomers program, MedalistTM, to provide device manufacturers with a wealth of new high-purity thermoplastic elastomer compounds along with a comprehensive body of tools and information for designers and processors. The Medalist initiative is a leap forward in our capability for serving medical manufacturers, said Andy Claytor, sales director. "While Teknor Apex has long supplied medical-grade compounds, the comprehensiveness of the Medalist range and the technical resources that accompany it will enable customers to use our program as a single source of elastomers for an array of applications and to eliminate guesswork in making material selections." The initial range of 33 Medalist compounds is already extensive. Shore A hardness spans an unusually broad range, from 5 to 87. Clear, translucent, and opaque formulations are available. The compounds fall into three series: Versatile Series (MD-100), whose widely differing grades meet many requirements encountered in medical manufacturing; Resilient Series (MD-200), formulated for enhanced toughness, oil-resistance, or heat-resistance; and Bondable Series (MD-300), for over-molding onto a variety of thermoplastic substrates. The three series are available worldwide. The accompanying table lists properties of four of the new Medalist compounds.  Will 33 Medalist compounds have been tested for compliance with ISO 10993-5 cytotoxicity standards and are free of animal-derived materials, vinyl, phthalates, latex, and additives not directly required for medical applications, said Lisa Charno, medical market manager. The sheer breadth of Medalist product offerings is remarkable ?from super-soft gels to elastomers that are semi-rigid like hard rubber. Grades are available for every major process in medical manufacturing, from injection molding to blow molding to extrusion of thin film. To aid designers in selecting the best compound for an application, and processors in optimizing production, Teknor Apex has prepared an expandable handbook and grade selector with complete information on every Medalist compound, including data on toxicology, sterilization, chemical resistance, and other properties, along with design considerations and processing guidelines. These are available at Teknor Apex's website dedicated to the product at www.medalistmd.com where data on all Medalist grades are presented. "The Medalist program is unique because it addresses such a wide range of performance requirements, subjects every one of the available grades to the same comprehensive testing, and addresses as many as possible of the issues that affect users of medical elastomers, including pending regulations," said Charno. "The whole point of the Medalist initiative is to provide梪p front梐ll of the information designers need to make the best raw material choice." 32 initial compounds for many medical requirements All Medalist elastomers meet ISO-10993-5 standards for non-toxicity and are compliant with U.S. Food & Drug Administration (FDA), RoHS, U.S. Conference of Northeastern Governors (CONEG), and California Proposition 65 requirements relevant to medical applications. They provide the advantages of thermoplastics ?outstanding processability, recyclability, colorability, and design freedom ?with the elasticity and tensile strength of conventional rubber.

Will 33 Medalist compounds have been tested for compliance with ISO 10993-5 cytotoxicity standards and are free of animal-derived materials, vinyl, phthalates, latex, and additives not directly required for medical applications, said Lisa Charno, medical market manager. The sheer breadth of Medalist product offerings is remarkable ?from super-soft gels to elastomers that are semi-rigid like hard rubber. Grades are available for every major process in medical manufacturing, from injection molding to blow molding to extrusion of thin film. To aid designers in selecting the best compound for an application, and processors in optimizing production, Teknor Apex has prepared an expandable handbook and grade selector with complete information on every Medalist compound, including data on toxicology, sterilization, chemical resistance, and other properties, along with design considerations and processing guidelines. These are available at Teknor Apex's website dedicated to the product at www.medalistmd.com where data on all Medalist grades are presented. "The Medalist program is unique because it addresses such a wide range of performance requirements, subjects every one of the available grades to the same comprehensive testing, and addresses as many as possible of the issues that affect users of medical elastomers, including pending regulations," said Charno. "The whole point of the Medalist initiative is to provide梪p front梐ll of the information designers need to make the best raw material choice." 32 initial compounds for many medical requirements All Medalist elastomers meet ISO-10993-5 standards for non-toxicity and are compliant with U.S. Food & Drug Administration (FDA), RoHS, U.S. Conference of Northeastern Governors (CONEG), and California Proposition 65 requirements relevant to medical applications. They provide the advantages of thermoplastics ?outstanding processability, recyclability, colorability, and design freedom ?with the elasticity and tensile strength of conventional rubber.  The 17 grades in the Medalist Versatile Series (MD-100) series are all clear or translucent and include a 5 Shore A ultra-soft clear gel; tubing grades optimized for softness, kink-resistance, alcohol resistance, or high clarity; high-flow injectionSNEAKERS

The 17 grades in the Medalist Versatile Series (MD-100) series are all clear or translucent and include a 5 Shore A ultra-soft clear gel; tubing grades optimized for softness, kink-resistance, alcohol resistance, or high clarity; high-flow injectionSNEAKERS