CONTINUOUS innovation aligned with—and anticipatory of—market needs has kept Heat and Control a strong player in the increasingly competitive food equipment manufacturing industry. A specialist in turnkey processing and packaging equipment, the company provides solutions for manufacturers of snack foods, meat products, ready-made meals and even pharmaceuticals.

Backed by nearly seven decades of experience in the industry, Heat and Control can customise solutions for traditional and new-generation products for processing, product handling, packaging and inspection, factoring in the design food manufacturers’ large-volume manufacturing, high quality and efficiency, hygiene and sanitation, and cost saving requirements. The company maintains an extensive network of after-sales personnel throughout the ASEAN region to provide support to customers and establish long-term relationships.

Knowing that factory equipment and machinery are required to operate 24/7, Heat and Control places a premium on reliability and efficiency. Ricky Ong, sales manager for Asia, noted at the ProPak Asia 2019 in Thailand that the company invests significantly in upgrading existing products to serve the market better.

“At Heat and Control, we’ve always been innovating equipment to stay abreast of the market and meet customers’ needs,” Mr. Ong said.

Ricky Ong, Heat and Control Sales Manager for Asia

Greater efficiency for product handling

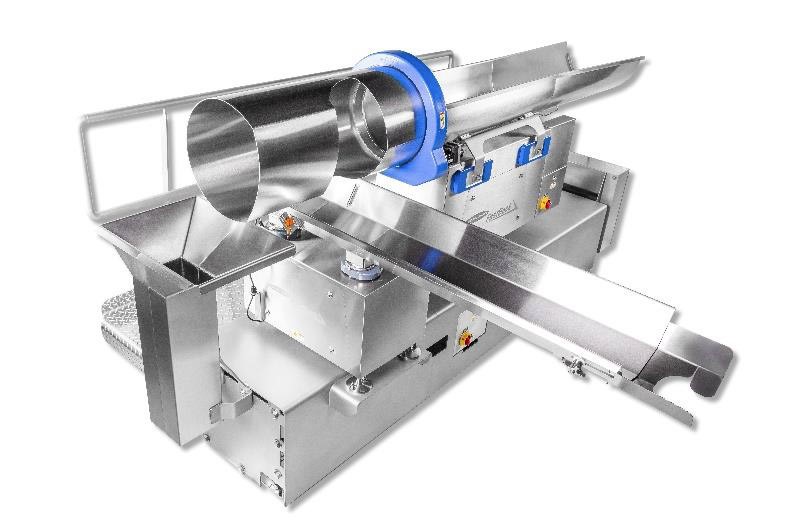

Heat and Control further elevates product handling and distribution efficiency with its latest generation of the FastBack® Horizontal Motion conveyor system. Incorporating the industry’s safest and only truly proportional gate – the FastBack® Revolution® Proportional Gate 3.0 – this conveyor system accurately proportions product flow from distribution conveyors to the weighing and packaging stations, in the process boosting not just efficiency but product quality, sanitation, operator safety as well.

Designed for snack foods, frozen fruits and vegetables, confectionery, cereal, pet food, meat, and poultry, French fries and any other product that conveys on a FastBack, the system eliminates product damage, ensures proportional, granular feeding to achieve product uniformity and improve packaging. While the main product supply flows, a cylindrical outlet rotates to divert a portion of the product. Individual weigher/bagger stations are allocated certain amounts, which means downstream stations are not left empty and need not wait for their allocation.

The fully closable Revolution Gate guarantees zero product leakage and cross-contamination, which also reduces waste. The absence of pinch points eliminates the risk of injury.

The Revolution Gate is optimised for both frozen, wet and dry applications and can withstand sub-freezing and washdown environments.

FastBack® Horizontal Motion conveyor system

Heat and Control also provides process equipment for snack foods and processed products such as meat products. For snack foods, the company has developed the E-FLO.

Ideal for potato chips, French fries and other root vegetables, the E-FLO Electroporation System improves product crunch, taste and texture. The patented system also reduces sugar and asparagine levels with its Pulse Electric Field Processing (PEF), which perforates the cell walls of the potato and creates micro holes to help wash out sugars and asparagine. This also helps lower the need for blanching.

The E-FLO’s compact design simplifies integration with new or existing processing lines with increase in yield according to Mr. Ong.

“Besides greater yield, the E-FLO has the capability to reduce acrylamide, which is one of the concerns now in the industry because of its cancer-causing attributes. This substance exists in starch products when they’re heated,” he said.

Shoring up sunrise markets

Mr. Ong sees more country markets emerging, if not growing even bigger, in the years ahead. “Existing markets such as Thailand are strong in that they have large production and export volumes. Indonesia and the Philippines are gaining more traction and have positive market outlook. These countries are producing more high-volume products,” he said.

To support the anticipated needs of these markets, Heat and Control continues to innovate and work with food manufacturers to achieve the kind of automation that they seek.

“In markets such as Indonesia and the Philippines demand on processed products is increasing due to changes in population, life style and economic situation,” he shared.

Aware of the unique characteristics of the different countries in Asia, Heat and Control tailor-fits its equipment to the trends in and needs of each market.

Due to increase in demand for processing and packaging needs in the region, Heat and Control has started manufacturing in China and India in addition to their regional HQ in Australia. The larger pool of skilled and professional manpower in the region also provide support to our users in ASEAN region.

Remaining relevant

Health and food safety issues and rising production costs are just some of the major challenges faced by food equipment manufacturers today. As consumers gain more purchasing power and awareness about trends across the global market, their requirements evolve as well, in many cases becoming even more stringent.

Heat and Control acknowledges a greater number of Asia’s food manufacturers are putting hygiene on top of their priorities list in light of food safety cases in Asia. But whilst companies expect a lot in terms of hygiene, they are also looking to reduce costs and increase savings and at the same time raise efficiency and product quality.

Mr. Ong said: “I’ve been in Heat and Control in this capacity looking after Asia for three decades now and I’ve seen how customers’ requirements have continued to change along with developments in the global market and in the region in particular. On top of all these expectations in terms of hygiene, costs, savings, production and safety, equipment manufacturers face a lot of pressure from tightening competition. The challenge is to stay ahead and make sure our machines are competitive enough not just in terms of their capability but also in terms of costs.”

This is why innovation remains a key driving force for Heat and Control. The company’s design process also revolves around machines that help boost the quality of the food or end product, be it as regards texture, crunch or overall look. The equipment must also be easy and safe to use and maintain, Mr. Ong concluded.

Highsnobiety Style