Technology group GEA will be at interpack (hall 3 / booth E46–E54) to exhibit a wide range of innovations and demonstrate its engineering expertise in the fields of meat, meat alternatives, cheese, bakery, confectionery, and pastry products. The focus will be on the benefits of GEA's line expertise, numerous technological innovations, and new solutions in automation and digitalisation for efficient and energy-saving production processes. All solutions create new opportunities to produce more sustainably.

The food industry is undergoing a transformation process. The current challenges in energy management, the ambition to conserve resources and optimise the circular economy, on the one hand, and the increasing demand for packaged food and higher food safety, on the other, require intelligent solutions in the processing and packaging process. "The challenges of sustainability, efficiency, and digitalisation are increasingly intertwined," says Rebecca Cullinan, CEO Food & Healthcare Technologies at GEA. "We have made it our mission to enable our customers to achieve long-term success and sustainable value creation with future-proof technologies and solutions – be it with individual plants, specialised production lines for entire processes, or the establishment of completely new production sites (greenfield projects) of customers. Our modern systems make a major contribution to achieving the sustainability goals of the food processing industry."

Soft cookies leave GEA's new electric baking oven, which produces efficiently and CO2 neutrally. (Source: GEA)

Overall plant efficiency through automation and line expertise

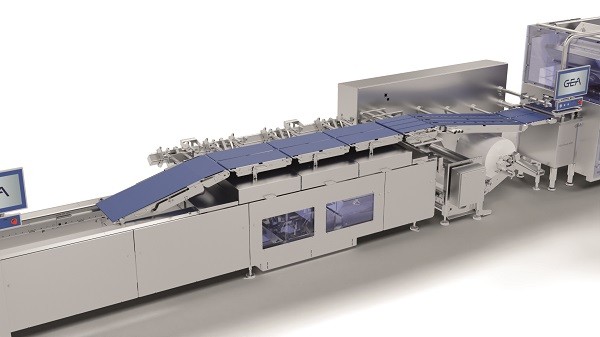

GEA's food processing & packaging range is currently one of the most comprehensive on the market. At Interpack, the new portfolio program will now be partly presented on a 25-meter-long production line for portion-precise slicing and loading into the thermoformer. GEA's aspiration for forward-looking line concepts is to ensure maximum plant effectiveness (OEE = Overall Equipment Effectiveness) through the best possible interaction of all line components. "Our lines are designed for the smallest possible footprint on the production area. This focus allows us to ensure more capacity per square meter with our future solutions, thereby minimising energy consumption per production area. A consistent modularity concept, which runs through the complete and innovative automation program, allows us to design individual solutions according to exact customer requirements," explains Steffen Bamberger, Head of Product Management Automation at GEA.

GEA's new electric baking oven for a carbon neutral and efficient production process for baked goods. (Source: GEA)

Many new technology highlights will be on display in the exhibited slicing and packaging line for consistently calibrated products, such as sausage and cheese slices.

- In the area of belt loading systems, the new OptiLoader family is being presented to the market for the first time. The OptiLoader stands for the best possible line integration and has the highest degree of modularity to ensure maximum output quantities while at the same time minimising the footprint of a complete GEA slicer line. For example, the OptiLoader 6000 is placed integrated in the thermoformer concept.

- GEA's new robotics solution GEA OptiRobot 6000 is in demand when it comes to the highest degree of automation combined with super-low labor costs and ample flexibility. The new robot enables differently shaped portions (stacked, shingled, overlapped, etc.) to be loaded into a packaging machine with any kind of laying pattern fully automatically.

- Another world premiere is the unveiling of GEA OptiBuffer. To ensure high line efficiency, it is imperative to avoid waiting times caused by components. In a slicing line, the reloading times of the slicer cause gaps in the product flow. However, a robot should run smoothly and continuously. "GEA solves this problem with a newly integrated, dynamic, and intelligent high-performance buffering system, with the help of which picking capacities of a robot system are effectively and exclusively used for inserting good portions into a packaging machine. This is currently unique on the market," explains Steffen Bamberger.

- The presentation of the new automation program at Interpack is rounded off by the innovative GEA PowerSort 6000 separating and sorting system, which can be configured exactly to customer requirements from the same modular system.

The new GEA OptiLoader 6000 is integrated into the thermoformer and shows the newly developed line concept of integrating individual components into the line in the best possible way. (Source: GEA)

More sustainable packaging solutions

Sustainability is one of the most important issues in the packaging market today, and one that all companies in the value chain must address. At Interpack, GEA will showcase:

- The new GEA PowerHeat zone heating system for energy-efficient processing of mono-materials in the GEA thermoformer, which enables energy savings of 25–30%.

- With the new GEA PowerJet longitudinal nozzle, it is possible to introduce the protective gas more uniformly into the packaging and keep the residual oxygen content at a constant 0.1%, which significantly counteracts product spoilage.

- The GEA V-Packer IM-IV, a new vertical packaging solution for particularly fragile products in the pastry and bakery sector.

- Technological updates for the proven GEA Aquarius TwistWrapper for lollipops.

- The GEA SmartPacker TwinTube for the production of larger pillow bags with a width of 160 mm.

GEA accelerates the digitisation process of its customers

Digitalisation and automation are decisive factors for more sustainable and energy-saving production. GEA is strongly focused on increasing customer value by increasing the transparency and efficiency of its equipment. For this purpose, the company is expanding the number of machines for which the new GEA SmartControl HMI operating panel, as well as GEA PerformancePlus digital services and the GEA Machine Data Interface (OPC UA) are available.

- GEA SmartControl HMI (Human-Machine Interface) GEA SmartControl HMI has been developed with a consistent user-centric approach that ensures maximum ease of use, transparency and safety.

- GEA PerformancePlus provides key indicators and analysis of machine health and performance at the touch of a button to ensure high performance throughout the entire machine life.

- GEA Machine Data Interface (OPC UA) allows customers to connect their machines easily and efficiently to internal control or monitoring systems and thus drive Industry 4.0 forward in real terms.

Further technology highlights at interpack

Manufacturers of baked goods, pasta, snacks, and confectionery products will receive detailed information at the GEA booth about the numerous other technological innovations that offer many advantages for more flexible and energy-efficient production. As a highlight, GEA will present a new electric oven and a retrofit kit for the conversion from gas to electric heating, which provides a carbon-neutral and efficient production process. For the pasta industry, the focus is on a new pre-dryer for pasta. Maximising air exchange at the product increases energy efficiency. The new multi-purpose gelatiniser is an all-in-one machine that combines the functions of the xTru-Former and the xTru-Cooker. The machine has the advantage of a smaller footprint and a lower energy consumption.